Floor attaching device for house decoration

A technology for fitting devices and floors, which can be used in buildings, building structures, etc., and can solve the problems of narrow floor edges, limited indoor space, and easy fatigue of workers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

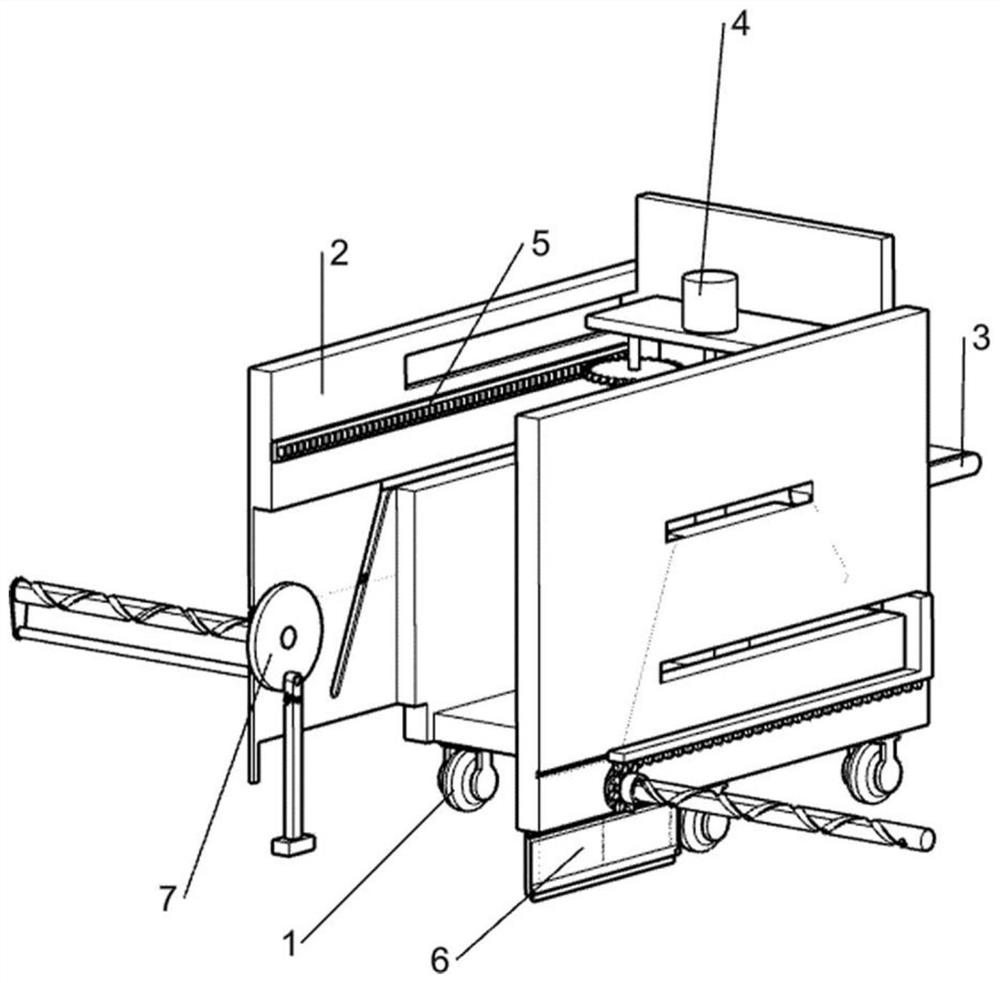

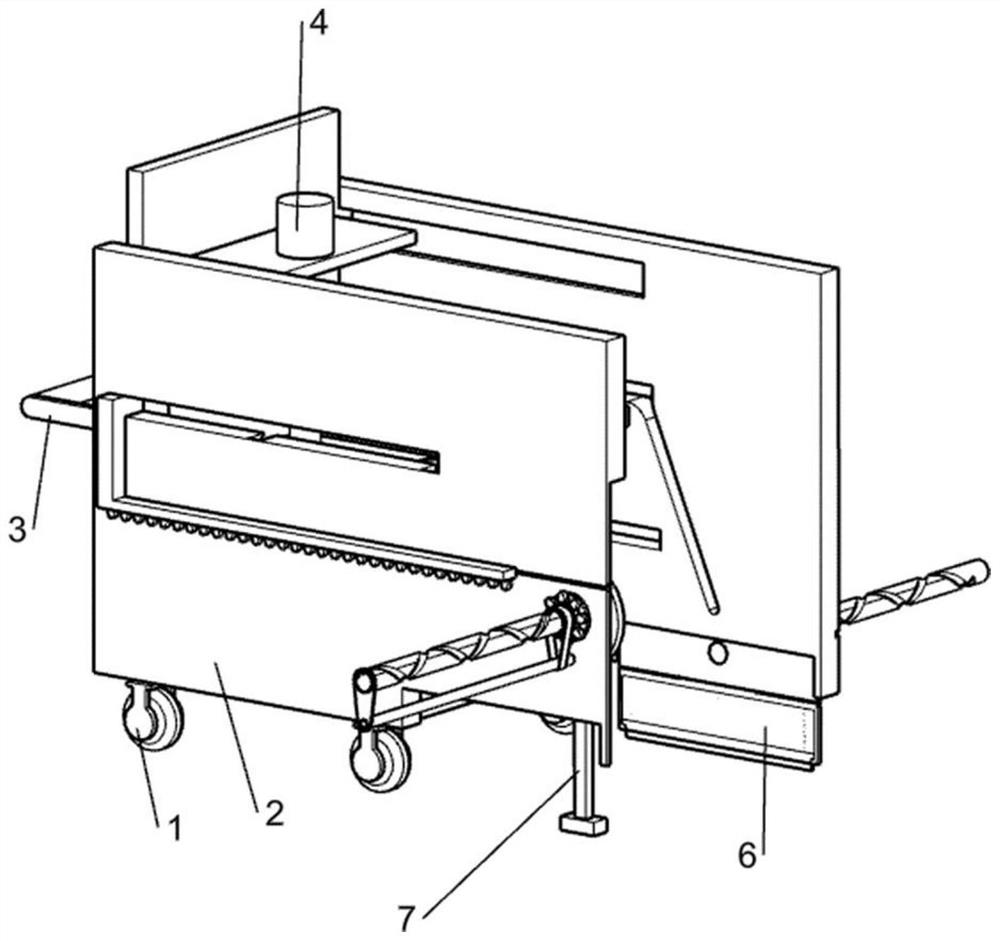

[0024] A floor bonding device for house decoration, such as Figure 1-7 As shown, it includes a universal wheel 1, an outer frame bracket 2, a push rod 3, a lifting mechanism 4, a moving mechanism 5 and a scraping mechanism 6, and the bottom of the outer frame bracket 2 is connected with a universal wheel 1 for distributed rotation, and the outer frame bracket 2 One side is fixed with a push rod 3 for convenient pushing, the lifting mechanism 4 is slidably connected to the outer frame support 2, the moving mechanism 5 is set on the lifting mechanism 4, and the scraping mechanism 6 is rotatably connected to the outer frame support 2 , Scraping mechanism 6 is used for fully smoothing the cement on the ground.

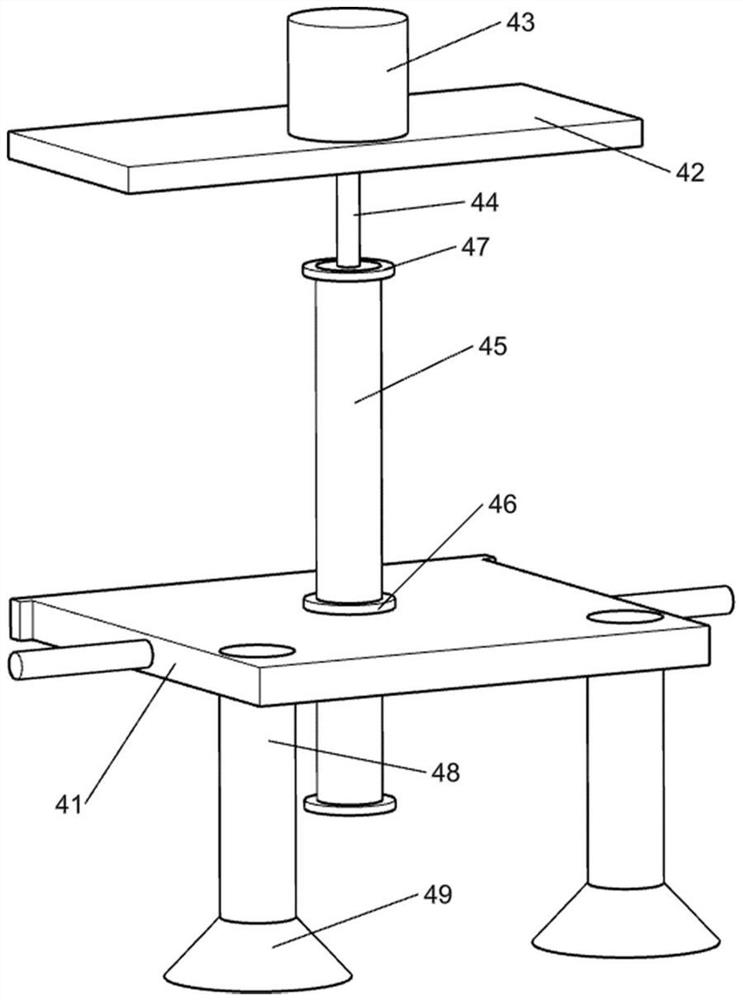

[0025] The lifting mechanism 4 includes a moving plate 411, a slide block 41, a support frame 42, a motor 43, a first power shaft 44, a transmission shaft 45, a sliding sleeve 46, a block 47, a first fixed rod 48 and a suction cup 49, and the moving plate 411 Slidingly c...

Embodiment 2

[0031] On the basis of Example 1, such as Figure 8 As shown, it also includes a fitting and pressing mechanism 7, which is arranged on the outer frame support 2, and the fitting and pressing mechanism 7 is used to make the floor and the ground closely fit, and the fitting and pressing mechanism 7 includes The third rack 71, the second looper 72, the second overrunning clutch 73, the second rotating gear 74, the second reciprocating screw 75, the fixed plate 76, the fixed disc 77, the second power shaft 78, the leather strip 79, the third The fixed rod 710 and the rubber hammer 711 are fixedly connected with the third rack 71 on the moving plate 411 away from the second rack 61, the third rack 71 is connected to the outer frame support 2 in a sliding manner, and the second looper 72 is connected in a rotational manner On the outer frame support 2 away from the first looper 62, the second looper 72 is fixedly connected with a second overrunning clutch 73, and the second overrun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com