Stay wire manufacturing platform

A technology for making platforms and operating platforms, which is applied in the installation of cable installation devices, electrical components, cables, etc. It can solve problems such as inconsistent processes, low work efficiency, and time-consuming and labor-intensive production of pulling wires, and achieve uniform installation and production processes and high work efficiency. Improves the effect of facilitating quick and efficient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

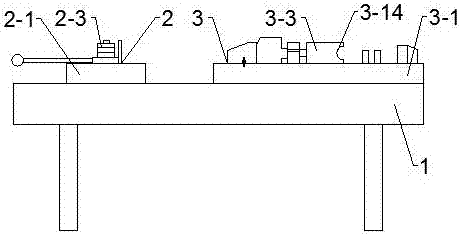

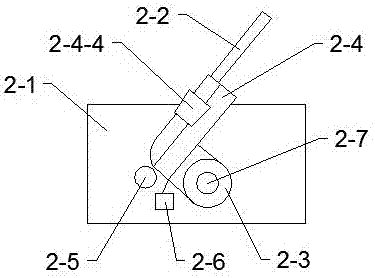

[0017] Such as Figure 1-4 As shown, a backguy making platform includes an operation platform 1, on which a backguy curver 2 and a wedge-shaped clamp installation device 3 are arranged; wherein the backguy curver 2 includes a support 2-1, and a support 2-1 There is a bending handle 2-2 and a positioning wheel 2-3 on the top, the bending handle 2-2 is connected with the positioning wheel 2-3 through the connecting plate 2-4, the bending handle rotates around the connection point, and the steel strand is placed on the positioning wheel Between the bending handle and the bending handle, turn the bending handle to make a certain arc on the steel strand; the wedge-shaped clamp installation device 3 includes a base 3-1, which is fixedly connected to the operating platform, and the base 3-1 is sequentially provided with a pusher 3 -2. The push plate 3-3, the support plate 3-4 and the positioning block 3-5, the pusher 3-2 and the push plate 3-3 are connected, and the pusher 3-2 is a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com