Sterling-pulse tube mixed cold finger adopting column spring phase modulation

A vascular, phasing technique applied to Stirling-vascular hybrid cold fingers. In the field of refrigeration, it can solve the problems of low theoretical efficiency of the refrigerator, inability to recover hot-end expansion work, and limited phase modulation ability, so as to achieve the effect of realizing effective work recovery, improving efficiency, and reducing cold-end vibration output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing:

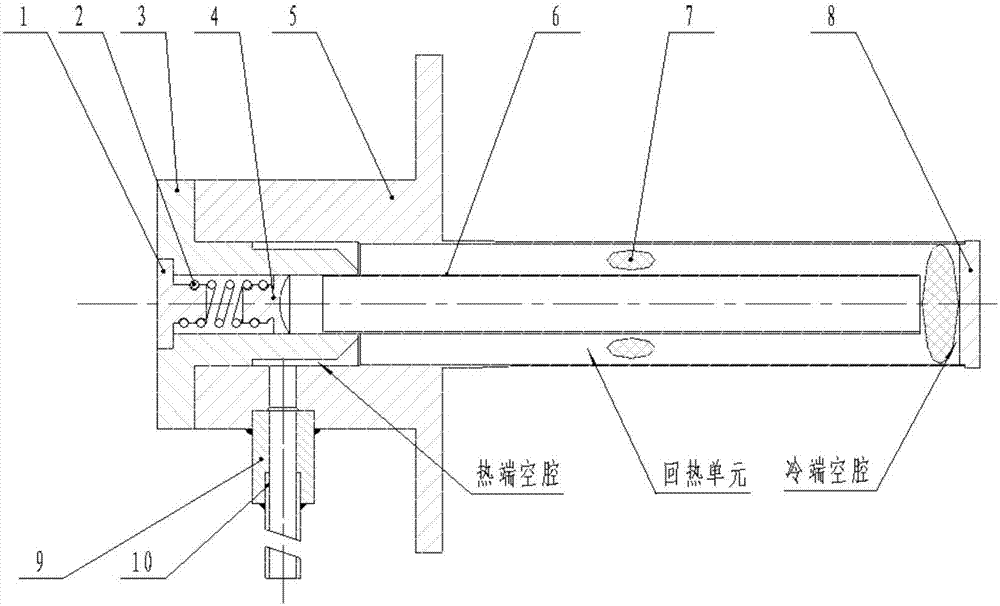

[0024] like figure 1 A Stirling-vessel hybrid cold finger using column spring phase modulation as shown includes an expansion cylinder and a vessel housing 6 embedded in the expansion cylinder and arranged coaxially with the expansion cylinder. Described expansion cylinder comprises expansion cylinder body 5, is installed in the hot end air distribution seat 3 of expansion cylinder body 5 hot end cavity openings, is installed in the cold cap 8 of expansion cylinder body 5 cold end cavity openings and is installed in expansion cylinder body 5. A connecting pipe 10 and a transition pipe 9 communicating with the hot end cavity on the cylinder block 5 . A mechanical phase adjustment device arranged coaxially with the vessel housing 6 is embedded in the gas distribution seat 3 at the hot end. The mechanical phase adjustment device includes a spring fixing seat 1 arranged at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com