Dust-accumulation-preventing natural circulation fluidized bed boiler

A fluidized bed boiler and natural circulation technology, applied in the field of boilers, can solve the problems of low efficiency, reduced heat exchange efficiency, loss of heat exchange function, etc., and achieve the possibility of increasing heat exchange efficiency, large degrees of freedom, and reducing interference Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

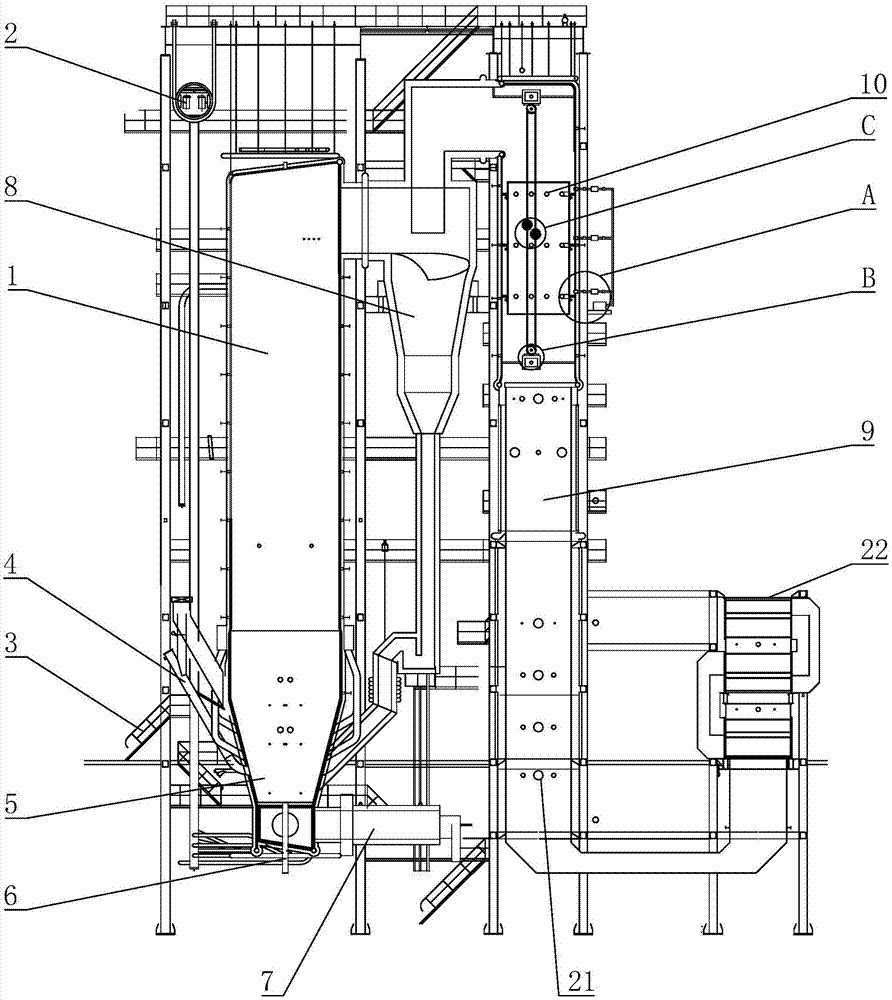

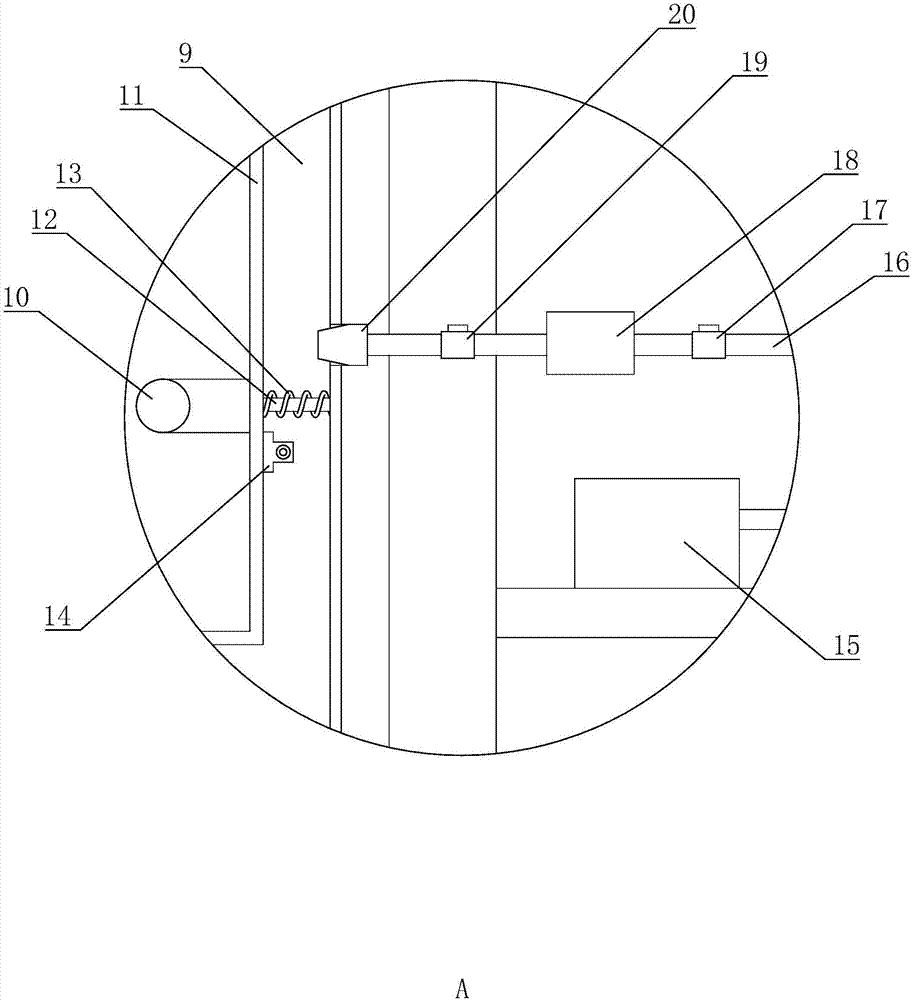

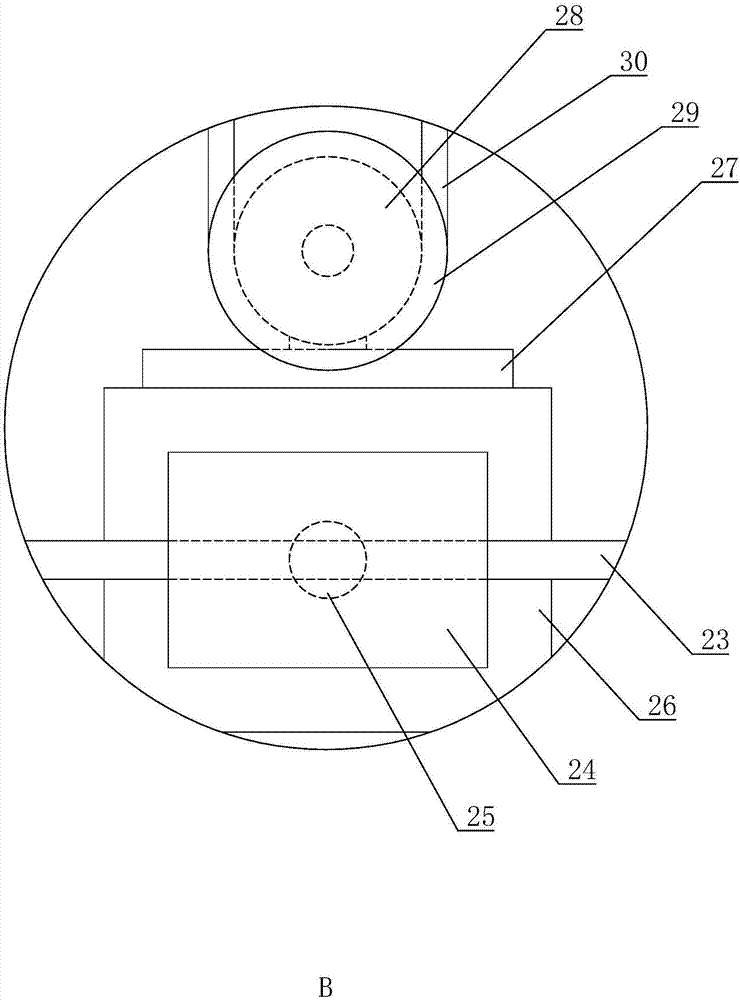

[0032] refer to Figure 1 to Figure 4 The present invention will be further described.

[0033] like figure 1 and figure 2 As shown, an anti-ashing natural circulating fluidized bed boiler includes a furnace 1, a drum 2 is installed above the furnace 1, and a feeder 3 and a blanking pipe 4 are externally connected to the bottom side of the furnace 1. The feeder 3. The blanking pipe 4 leads to the combustion chamber 5 at the lower part of the furnace chamber 1. The lower part of the combustion chamber 5 is arranged with a slag discharge pipe 6, an ignition device 7 is arranged under the combustion chamber 5, and a cyclone separator is arranged vertically on the right side of the furnace chamber 1. 8. A vertical shaft 9 is arranged on the right side of the cyclone separator 8, an economizer 10 is arranged above the shaft 9, the economizers 10 are arranged in series, and the economizer 10 is a membrane type economizer 10, The outer side of the economizer 10 is fixedly connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com