Method for preparing flexible composite material with low filler content and high electrical conductivity on basis of swelling penetration method

A technology of filler content and composite materials, applied in the field of composite materials, can solve the problems of high carbon nanotube content, affecting flexibility and sensitivity, etc., and achieve the effects of simple method, low cost and low resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

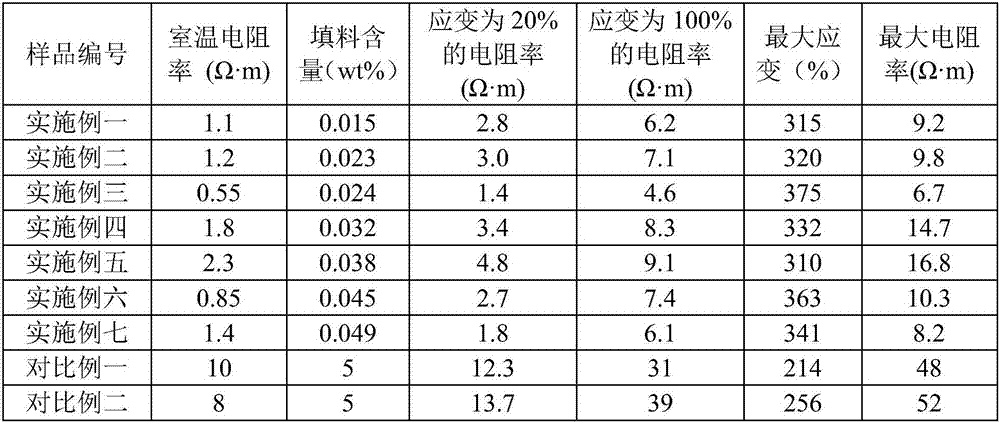

Examples

Embodiment 1

[0042] Weigh 10g of polydimethylsiloxane and 0.05g of crosslinking agent hydroxy silicone oil, cure at 100°C for 2h, and then swell in hexane for 15min. Configure a mixed solution of DMF and water (weight ratio DMF:water=10:1), then add CNTs at a concentration of 0.3 mg / ml, and ultrasonically disperse to obtain a suspension, wherein the CNTs have a diameter of 2 nm and a length of 0.5 μm; the swelling The rubber was placed in the suspension of CNTs, and heated in a water bath at 30°C for 12 hours; the composite material was taken out, ultrasonically cleaned with deionized water for 1 hour, and then dried in a 60°C oven for 12 hours until completely dry.

Embodiment 2

[0044] Weigh 10g of polydimethylsiloxane and 2g of crosslinking agent 2,5-dimethyl-2,5-bis(tert-butylperoxy)hexane, cure at 100°C for 2h, then place in toluene to swell 180min. Configure a mixed solution of NMP and water (weight ratio NMP: water = 1: 10), then add CNTs at a concentration of 1.5 mg / ml, and ultrasonically disperse to obtain a suspension, wherein the CNTs have a diameter of 30 nm and a length of 100 μm; the swollen The rubber was placed in the suspension of CNTs, heated in a water bath at 90°C for 3 hours and ultrasonically cleaned for 3 hours; the composite material was taken out, ultrasonically cleaned with deionized water for 1 hour, and then dried in a 60°C oven for 12 hours until completely dry.

Embodiment 3

[0046] Weigh 10g of methyl vinyl silicone rubber and 0.5g of cross-linking agent dicumyl peroxide, cure at 100°C for 2h, and then swell in toluene for 60min. Prepare a mixed solution of DMF and water (weight ratio DMF:water=4:1), then add CNTs at a concentration of 1.5 mg / ml, and ultrasonically disperse to obtain a suspension, wherein the diameter of the CNTs is 20 nm and the length is 30 μm; the swollen The rubber was placed in the suspension of CNTs, and heated in a water bath at 70°C for 3 hours with ultrasound; the composite material was taken out, cleaned ultrasonically with deionized water for 1 hour, and then dried in an oven at 60°C for 12 hours until completely dry.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com