2-amino-4-nitrophenol-6-sulfonic acid dye intermediate waste liquid modified high-efficient water reducing agent

A dye intermediate and high-efficiency water reducer technology, applied in the field of water reducer production, can solve the problems of high production cost, easy bleeding, low application level, etc., and achieve good product workability, no three wastes discharge, and a short reaction cycle short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A 2-amino-4-nitrophenol-6-sulfonic acid dye intermediate waste liquid modified high-efficiency water reducer, comprising the following raw materials in parts by weight: 70 parts of sodium aminobenzenesulfonate, 58 parts of phenol, water 40 parts, 92 parts of formaldehyde, 16 parts of acrylic acid, 5 parts of sodium hydroxide, 160 parts of 2-amino-4-nitrophenol-6-sulfonic acid dye intermediate waste liquid.

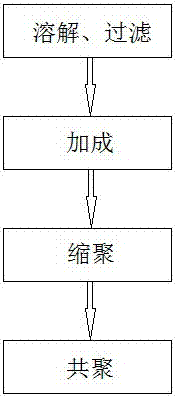

[0023] Its preparation method comprises the following steps:

[0024] (1) Dissolving and filtering: add an appropriate amount of water to the reaction kettle, then add sodium sulfanilate and phenol respectively, raise the temperature of the reaction kettle to 85-92°C, and stir for 1 hour;

[0025] (2) Addition: Slowly add sodium hydroxide to the reaction kettle to adjust the pH of the solution to 7.6-8.2;

[0026] (3) Polycondensation: raise the temperature of the reactor to 90-95°C, slowly add formaldehyde dropwise to it, so that the formaldehyde will be dropped w...

Embodiment 2

[0030] A 2-amino-4-nitrophenol-6-sulfonic acid dye intermediate waste liquid modified high-efficiency water reducer, including the following raw materials in parts by weight: 65 parts of sodium aminobenzenesulfonate, 65 parts of phenol, and 20 parts of water 100 parts of formaldehyde, 15 parts of acrylic acid, 40 parts of sodium hydroxide, 150 parts of 2-amino-4-nitrophenol-6-sulfonic acid dye intermediate waste liquid.

[0031] Its preparation method comprises the following steps:

[0032] (1) Dissolving and filtering: add an appropriate amount of water to the reaction kettle, then add sodium sulfanilate and phenol respectively, raise the temperature of the reaction kettle to 85-92°C, and stir for 2 hours;

[0033] (2) Addition: Slowly add sodium hydroxide to the reaction kettle to adjust the pH of the solution to 7.6-8.2;

[0034] (3) Polycondensation: raise the temperature of the reactor to 90-95°C, slowly add formaldehyde dropwise to it, so that the formaldehyde will be d...

Embodiment 3

[0038] A 2-amino-4-nitrophenol-6-sulfonic acid dye intermediate waste liquid modified high-efficiency water reducer, including the following raw materials in parts by weight: 75 parts of sodium aminobenzenesulfonate, 62 parts of phenol, and 100 parts of water 98 parts, 98 parts of formaldehyde, 18 parts of acrylic acid, 35 parts of sodium hydroxide, 240 parts of 2-amino-4-nitrophenol-6-sulfonic acid dye intermediate waste liquid.

[0039] Its preparation method comprises the following steps:

[0040] (1) Dissolving and filtering: Add an appropriate amount of water to the reaction kettle, then add sodium sulfanil and phenol respectively, raise the temperature of the reaction kettle to 85-92°C, and stir for 1.5 hours;

[0041] (2) Addition: Slowly add sodium hydroxide to the reaction kettle to adjust the pH of the solution to 7.6-8.2;

[0042] (3) Polycondensation: raise the temperature of the reactor to 90-95°C, slowly add formaldehyde dropwise to it, so that the formaldehyde ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com