Ceramic brick with super-flat glaze without glaze defect and preparation process of ceramic brick

A preparation process and ceramic tile technology, which is applied in the field of architectural ceramics, can solve the problems of low flatness of the glazed surface, reduce dark ceramic tiles, and low clarity, achieve a smooth and delicate glazed surface, solve the problem of glazed orange peel, Reduce the effect of pinhole defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

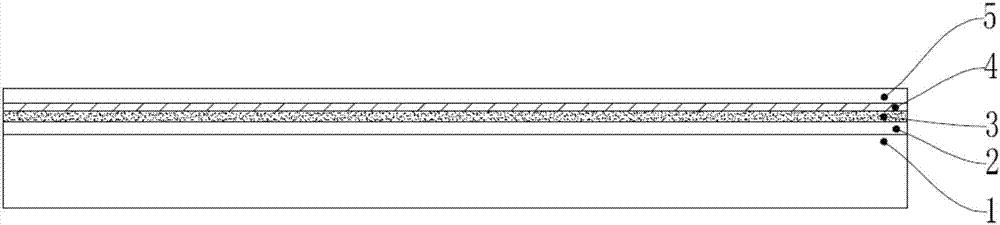

Image

Examples

Embodiment 1

[0024] Embodiment 1-a kind of preparation technology that has ultra-flat glazed surface and the ceramic tile without glazed surface defect, comprises the steps:

[0025] 1. Preparation of printing paste:

[0026] The raw material composition ratio of printing paste is shown in the following table:

[0027] raw material

Waterborne Tackifying Resin

ethylene glycol

Anti-sticking agent

water

percentage

8%

3%

2%

2%

85%

[0028] Mix the above raw materials to obtain a printing paste containing a water-based tackifying resin, wherein the viscosity of the printing paste is 2500MPa.S;

[0029] 2. Preparation steps:

[0030] (1) brick adobe is prepared according to a conventional preparation method, and an underglaze is poured on the surface of the adobe to form an underglaze layer;

[0031] (2) Ink-jet / screen printing is carried out on the surface of the brick adobe with the bottom glaze layer to form a pattern layer...

Embodiment 2

[0034] Embodiment 2-a kind of preparation technology that has ultra-flat glazed surface and the ceramic brick without glazed surface defect, comprises the steps:

[0035] 1. Preparation of printing paste:

[0036] The raw material composition ratio of printing paste is shown in the following table:

[0037] raw material

Waterborne Tackifying Resin

ethylene glycol

Anti-sticking agent

water

percentage

12%

3.5%

2.5%

2%

80%

[0038] Mix the above raw materials to obtain a printing paste containing a water-based tackifying resin, wherein the viscosity of the printing paste is 2000MPa.S;

[0039] 2. Preparation steps:

[0040] (1) brick adobe is prepared according to a conventional preparation method, and an underglaze is poured on the surface of the adobe to form an underglaze layer;

[0041] (2) Ink-jet / screen printing is carried out on the surface of the brick adobe with the bottom glaze layer to form a pattern...

Embodiment 3

[0044] Embodiment 3-a kind of preparation technology that has ultra-flat glazed surface and the ceramic brick without glazed surface defect, comprises the steps:

[0045] 1. Preparation of printing paste:

[0046] The raw material composition ratio of printing paste is shown in the following table:

[0047] raw material

Waterborne Tackifying Resin

ethylene glycol

Anti-sticking agent

water

percentage

8%

5%

5%

2%

80%

[0048] Mix the above raw materials to obtain a printing paste containing a water-based tackifying resin, wherein the viscosity of the printing paste is 3000MPa.S;

[0049] 2. Preparation steps:

[0050] (1) brick adobe is prepared according to a conventional preparation method, and an underglaze is poured on the surface of the adobe to form an underglaze layer;

[0051] (2) Ink-jet / screen printing is carried out on the surface of the brick adobe with the bottom glaze layer to form a pattern laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com