Environmental-friendly ceramic material processing device and method

A technology of ceramic materials and processing devices, applied in the field of ceramic processing, can solve the problems of low production efficiency, insufficient intelligence and high cost, and achieve the effect of ensuring environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with accompanying drawing:

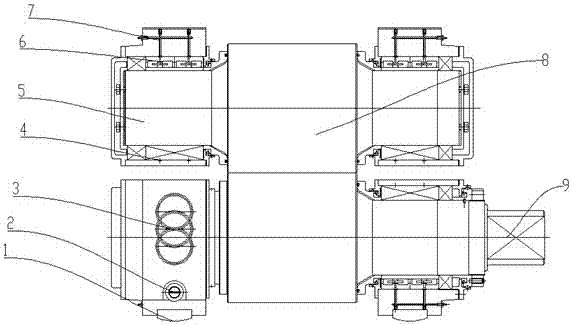

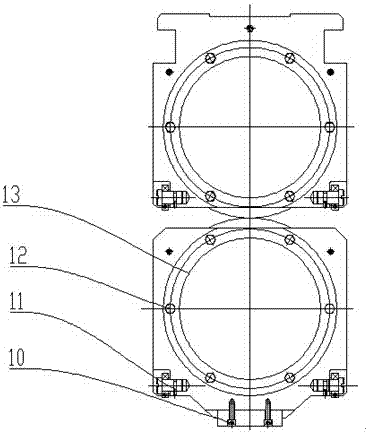

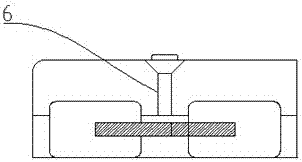

[0032] Such as Figure 1-Figure 3As shown, an environment-friendly ceramic material processing device and processing method include a vacuum machine 1, a molding chamber 5, a sintering chamber 8 and a cleaner 11. A pressure regulating valve 2 is installed on the upper end of the vacuum machine 1 to vacuumize the equipment. , and adjusted to a suitable pressure, the upper end of the pressure regulating valve 2 is installed with a radiator 3, which has a good heat dissipation effect on the equipment, and the upper end of the radiator 3 is installed with a compactor 4, which can compact the ceramic raw materials and improve the yield. Density, the upper end of the compactor 4 is connected with a molding chamber 5 for preliminary molding of the ceramics. A heater 6 is installed at the upper end of the molding chamber 5 to heat the furnace for sintering. A thermometer 7 is insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com