Conductive asphalt concrete

A conductive asphalt and concrete technology, applied in the field of road engineering materials, can solve the problem of difficult to ensure the electrical conductivity and road performance of asphalt concrete at the same time, and achieve the effects of preventing or pavement cracks, prolonging durability, and improving low-temperature crack resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

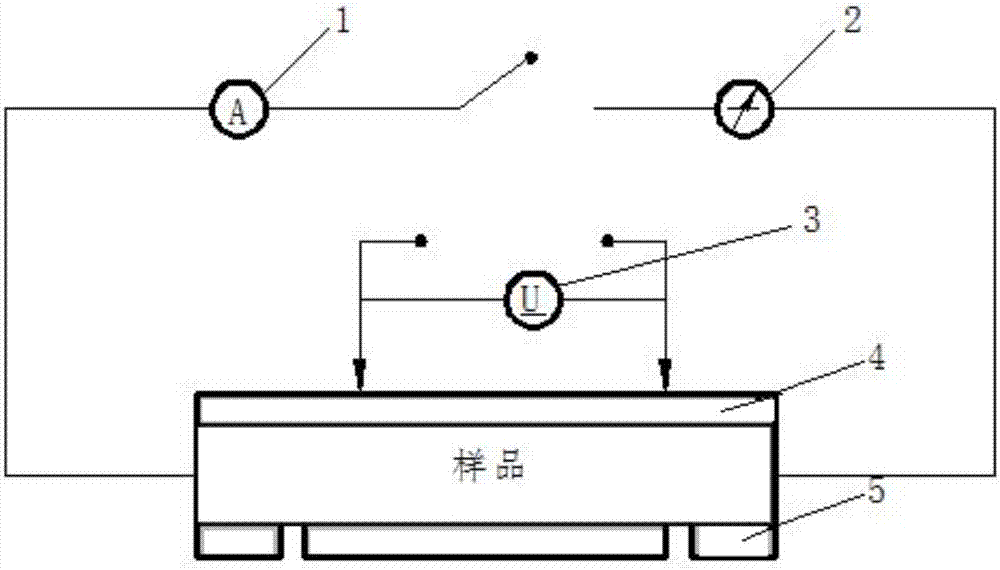

Image

Examples

Embodiment 1

[0026] This embodiment provides a conductive asphalt concrete, the aggregate gradation type used is AC-13 type, the asphalt used is SBS modified asphalt, including the following raw materials in parts by mass:

[0027] 98 parts of aggregate, 2 parts of mineral powder filler, 8 parts of asphalt, 11 parts of conductive material, 2 parts of 3,4-dihydroxycinnamic acid conductivity improver, trimethoxy-2-azidobenzenesulfonylethylsilane coupling 0.01 part of agent, 0.5 part of bis(octylphenol polyoxyethylene ether) phosphoester dispersant; the conductive material used is a mixture of nano-silver solution, silver-plated conductive yarn, and black titanium powder.

[0028] Prepare according to the following preparation method:

[0029] Step 1. Add black titanium powder into nano-silver solution with a mass concentration of 20% to 40%, stir evenly, soak the silver-plated conductive yarn for 40-60 minutes, heat it to a colloidal suspension, and then cool it naturally to obtain a conduct...

Embodiment 2

[0033] This embodiment provides a conductive asphalt concrete, the raw material ratio is as follows:

[0034] 91 parts of aggregate, 9 parts of mineral powder filler, 3 parts of asphalt, 0.7 part of conductive material, 0.01 part of asphalt conductivity improver, 2 parts of coupling agent, and 0.01 part of dispersant.

[0035] The preparation method of this embodiment is the same as that of Example 1.

Embodiment 3

[0037] This embodiment provides a conductive asphalt concrete, the raw material ratio is as follows:

[0038] 94.7 parts of aggregate, 5.3 parts of mineral powder filler, 4.9 parts of asphalt, 8 parts of conductive material, 1.1 parts of asphalt conductive improver, 0.9 part of coupling agent, and 0.18 part of dispersant.

[0039] The preparation method of this embodiment is the same as that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com