Disc part code scanning and alignment mechanism

A disk-type parts and disk-shaped technology, which is applied in the field of code-scanning and alignment mechanisms for disk-type parts, can solve the problems of not having the alignment function of disk-type parts and the inability to guarantee the position requirements of disk-type parts, so as to meet the position requirements , ensuring synchronization and improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

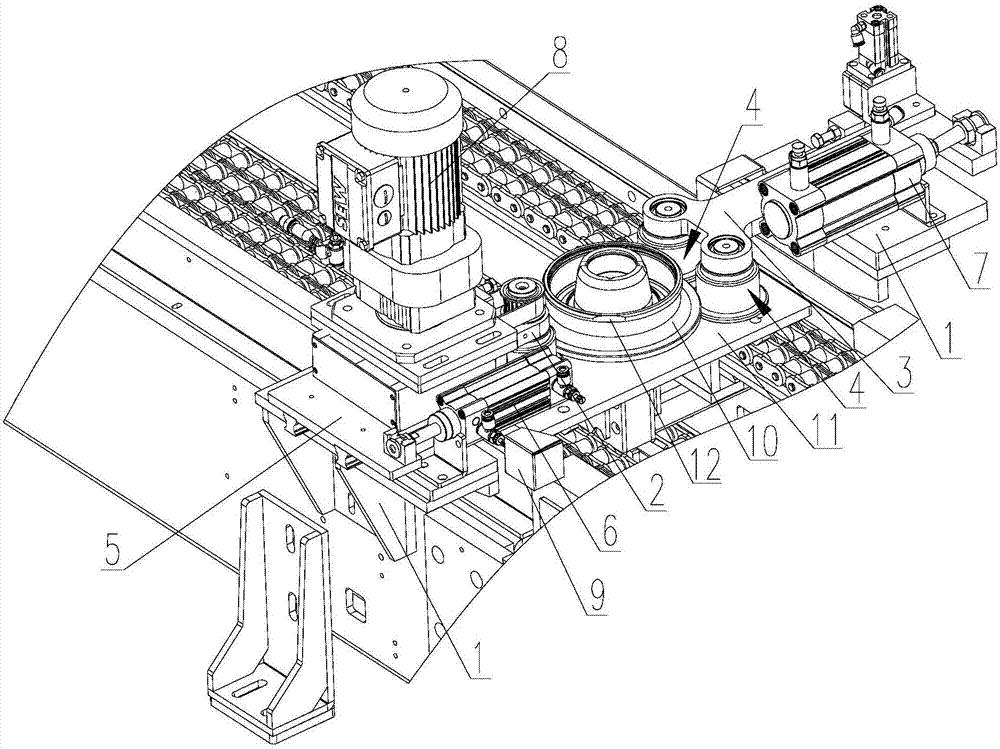

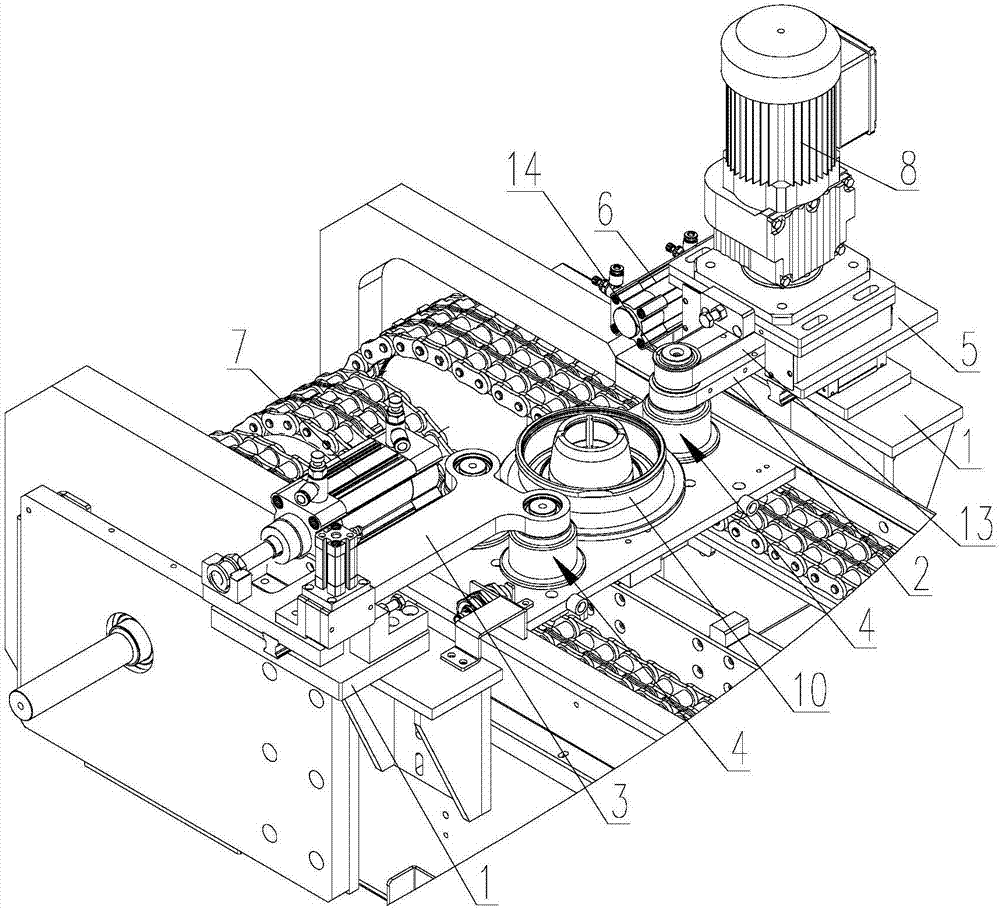

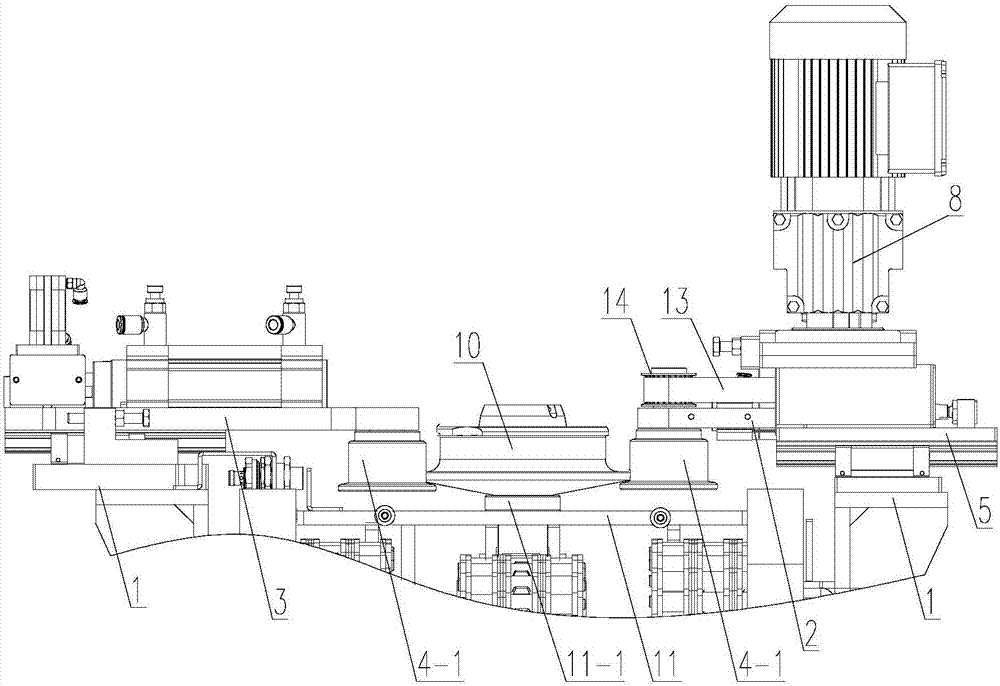

[0026] Such as Figure 1-5 As shown, a code scanning and alignment mechanism for disc parts is used to align disc parts 10 placed on a transfer pallet 11. The disc parts 10 are disc-shaped, and the outer peripheral surface of the disc parts 10 An identification code 12 is arranged on the upper part, and the alignment mechanism includes a mounting frame 1, a controller, and an oppositely arranged active yoke 2 and driven yoke 3, the inner ends of the active yoke 2 and the inner ends of the driven yoke 3 are both The rotation is provided with friction wheels 4, and there are at least three friction wheels 4;

[0027] A slide plate 5 is slidably arranged on the mounting frame 1, and the active yoke 2 is fixed on the slide plate 5. Power device, the first power device is used to drive the active yoke 2 on the slide plate 5 to move closer or farther away from the driven yoke 3, and the second power device is used to drive the driven yoke 3 to move closer or farther away from the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com