Lithium strip composite calendaring device and method thereof

A technology of calendering device and lithium belt, which is applied in lamination devices, chemical instruments and methods, lamination, etc., can solve the problems of inability to ensure stable quality, low work efficiency and yield, and products affecting production costs, etc. Achieve close compounding, improve production quality and efficiency, and achieve good production quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

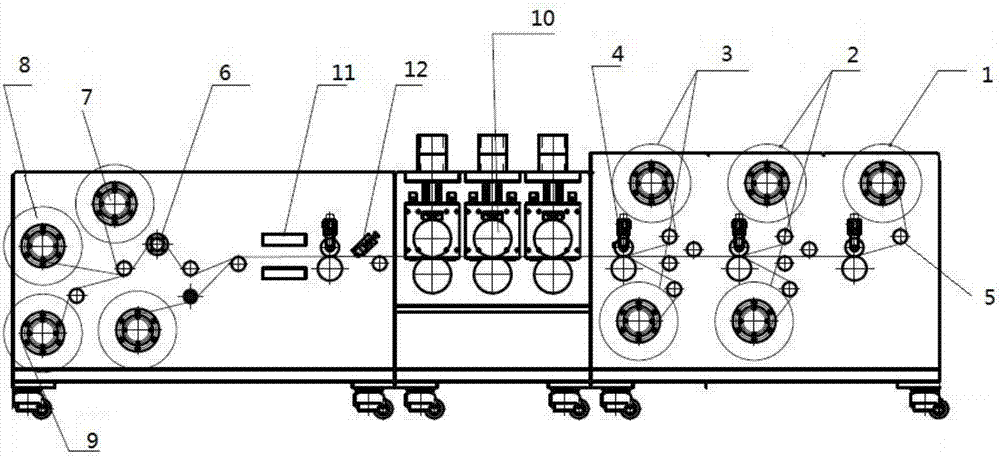

[0019] A lithium belt composite calendering device, comprising a feeding device, a rolling device, and a winding device. The feeding device includes a metal foil unwinding shaft, a lithium belt unwinding shaft 2 and a PE unwinding shaft 3 arranged in sequence. The metal of this embodiment The foil unwinding shaft is a copper foil unwinding shaft 1. The lithium belt unwinding shaft 2 and the PE unwinding shaft 3 are both symmetrically arranged on both sides of the metal foil; the feeding device and the winding device also include a traction device 4 And several auxiliary wheels 5. The winding device includes a tension roller 6, a waste PE winding 7, a composite winding shaft 8 and a flash winding shaft 9. The roller-driven calendering device is a multi-stage roller-driven calender wheel 10. A thickness gauge is also arranged between the win...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com