Injection molding machine material hopper magnetic suction device

A technology of injection molding machine and magnetic suction, applied in the field of plastic injection, which can solve the problems of iron fragments entering the barrel, blockage of the injection port, and inability to inject.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

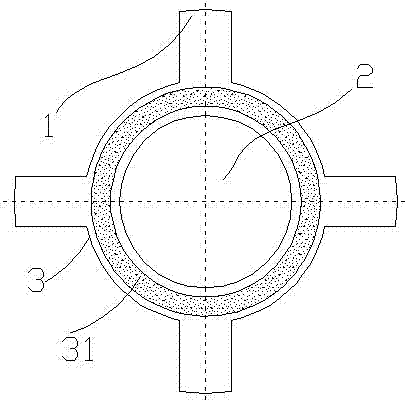

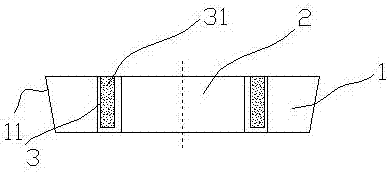

[0008] The invention discloses the magnetic attraction of the injection molding machine hopper, such as figure 1 , 2 As shown, its special diameter is that the periphery 1 of the magnetic attraction is cross-shaped, the edge 11 has a slope, the inner circle 2 is perforated, and the circle 3 with a cavity is formed in the middle, and the magnetic ring 31 is placed in the cavity.

[0009] The magnetic suction of the hopper of the injection molding machine of the present invention, in use, as long as the technician puts the magnetic suction into the feeding port of the injection molding machine, the magnetic ring will generate a magnetic field in the effective range of the feeding port without affecting the feeding, and the plastic will be perforated from the center and the hopper wall into the barrel.

[0010] Those skilled in the art will understand that without departing from the present invention, appropriate adjustments can be made to the disclosed configuration, for exampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com