Surface spraying protective paint spraying auxiliary device for robot machining

A robot processing and surface spraying technology, applied in the direction of spraying device, etc., can solve the problems of low mixing efficiency, inability to achieve full stirring, and dead corner of stirring device, etc., to achieve the effect of improving stirring efficiency, ensuring smoothness and avoiding dead corner of stirring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

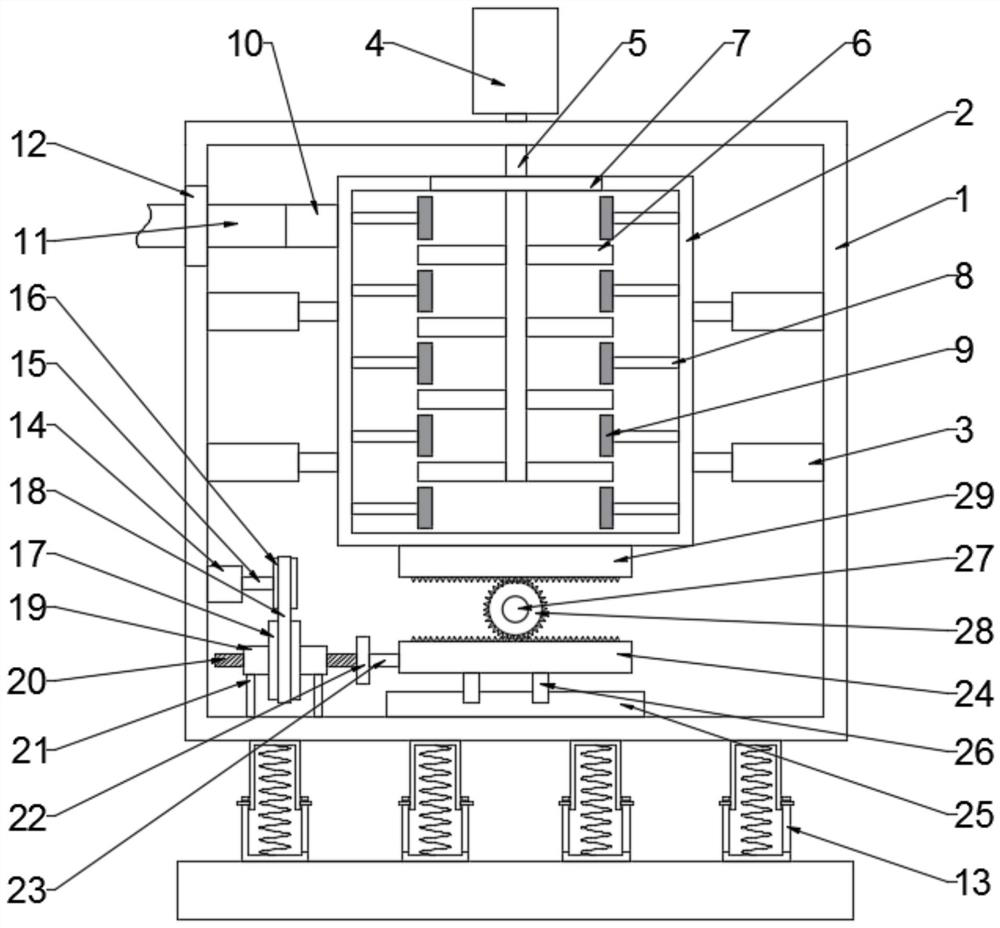

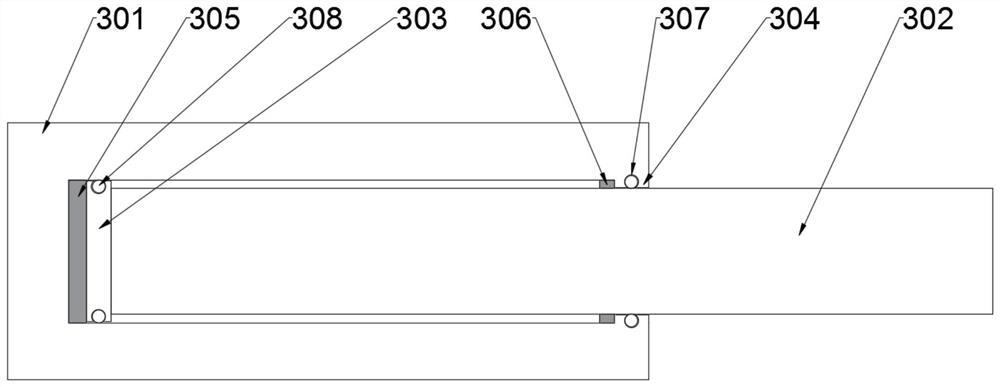

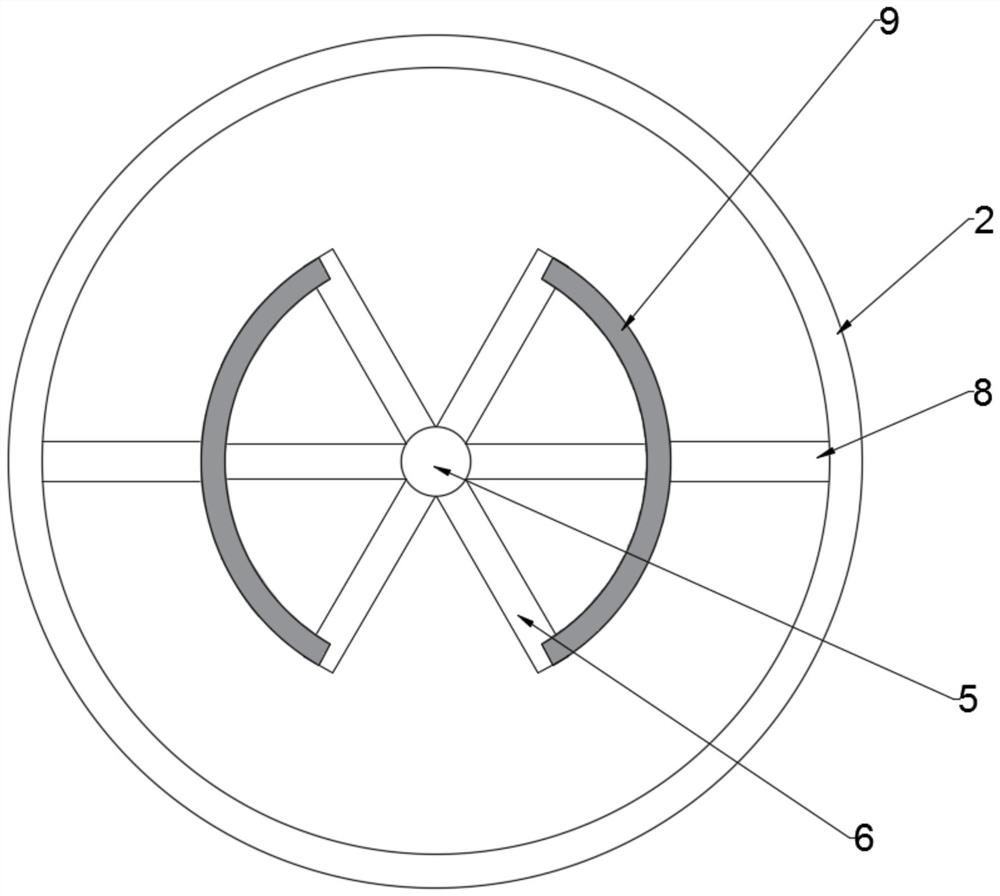

[0040] see figure 1 and image 3 , an auxiliary device for surface spraying protective paint spraying for robot processing, comprising a body 1 and an inner cylinder 2 arranged inside the body 1, and a plurality of lateral telescopic limit mechanisms 3 are connected between the inner cylinder 2 and the body 1. The top is provided with a first motor 4, the output end of the first motor 4 is connected with a stirring shaft 5, the stirring shaft 5 is arranged through the body 1 and the inner cylinder 2, and the inner cylinder 2 is provided with a bar-shaped groove that matches the stirring shaft 5. 7. There are several groups of stirring rods 6 fixed on the outer wall of the stirring shaft 5. Each group of stirring rods 6 includes a plurality of stirring rods 6 distributed in a ring shape. Five groups of support rods 8 are symmetrically arranged on the inner wall of the inner cylinder 2. The end of 8 is connected with a stirring plate 9, the stirring plate 9 and the stirring rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com