Jig for notebook computer LOGO press fit

A notebook computer and fixture technology, applied in the direction of manufacturing tools, hand-held tools, workpiece clamping devices, etc., can solve the problems of inconvenient operation, high labor intensity, unstable workpiece positioning, etc., and achieve the goal of improving versatility and ensuring precision Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

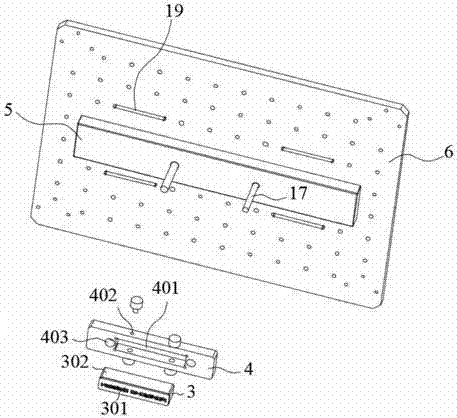

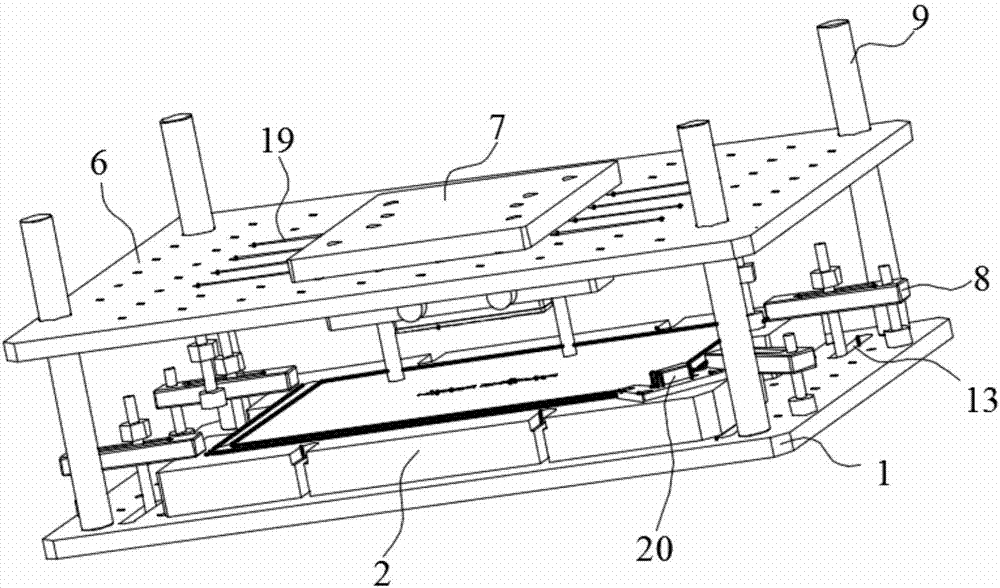

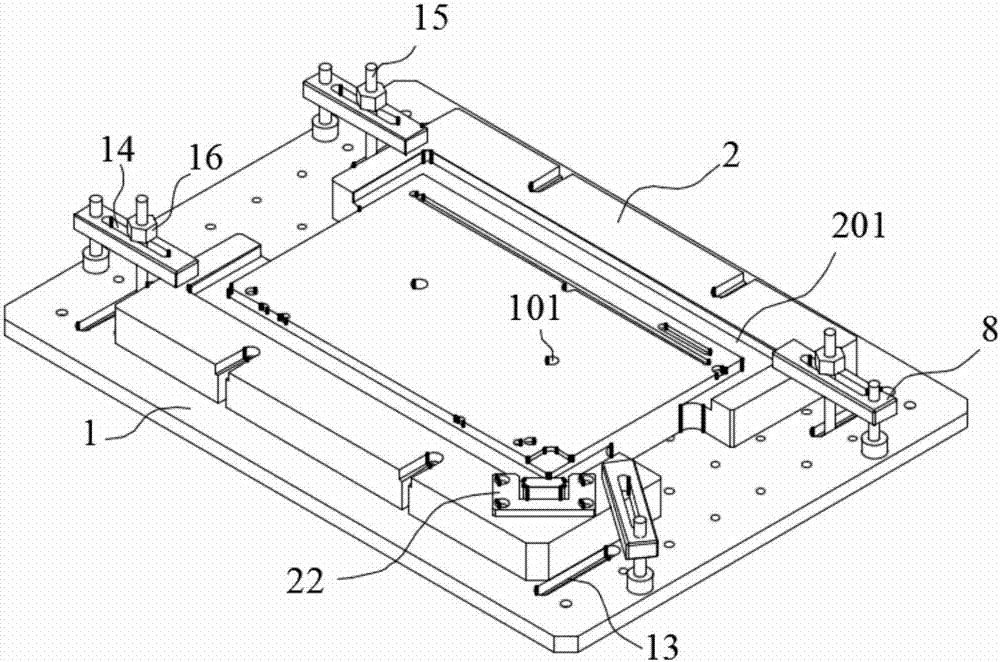

[0028] Embodiment 1: A fixture for laptop computer LOGO lamination, including a base plate 1, a base plate 2, an indenter 3, an indenter fixing plate 4, a mounting plate 5, a movable plate 6 and a transition plate 7, the base plate 1 Installed on the workbench of the pressing machine, the base plate 2 is fixedly connected to the base plate 1 through a plurality of pressing plates 8, and the base plate 1 and the movable plate 6 are connected by at least two guide posts 9, and the at least two guide posts 9 are respectively Located on both sides of the bottom plate 1, the pressure head fixing plate 4 and the mounting plate 5 are installed and connected to the lower surface of the movable plate 6, and the transition plate 7 is installed on the upper surface of the movable plate 6 and is in contact with the piston rod of the power cylinder;

[0029] Both ends of the bottom plate 1 are provided with a plurality of strip-shaped through holes 13, and the plurality of pressure plates 8...

Embodiment 2

[0034] Embodiment 2: A fixture for laptop computer LOGO lamination, including a base plate 1, a base plate 2, an indenter 3, an indenter fixing plate 4, a mounting plate 5, a movable plate 6 and a transition plate 7, the base plate 1 Installed on the workbench of the pressing machine, the base plate 2 is fixedly connected to the base plate 1 through a plurality of pressing plates 8, and the base plate 1 and the movable plate 6 are connected by at least two guide posts 9, and the at least two guide posts 9 are respectively Located on both sides of the bottom plate 1, the pressure head fixing plate 4 and the mounting plate 5 are installed and connected to the lower surface of the movable plate 6, and the transition plate 7 is installed on the upper surface of the movable plate 6 and is in contact with the piston rod of the power cylinder;

[0035] Both ends of the bottom plate 1 are provided with a plurality of strip-shaped through holes 13, and the plurality of pressure plates 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com