Combined gasket and automatic mounting and pasting jacking mechanism and welding process of combined gasket

A gasket and top-tight technology, applied in welding equipment, welding medium, welding equipment, etc., can solve the problem of inability to manually install gaskets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

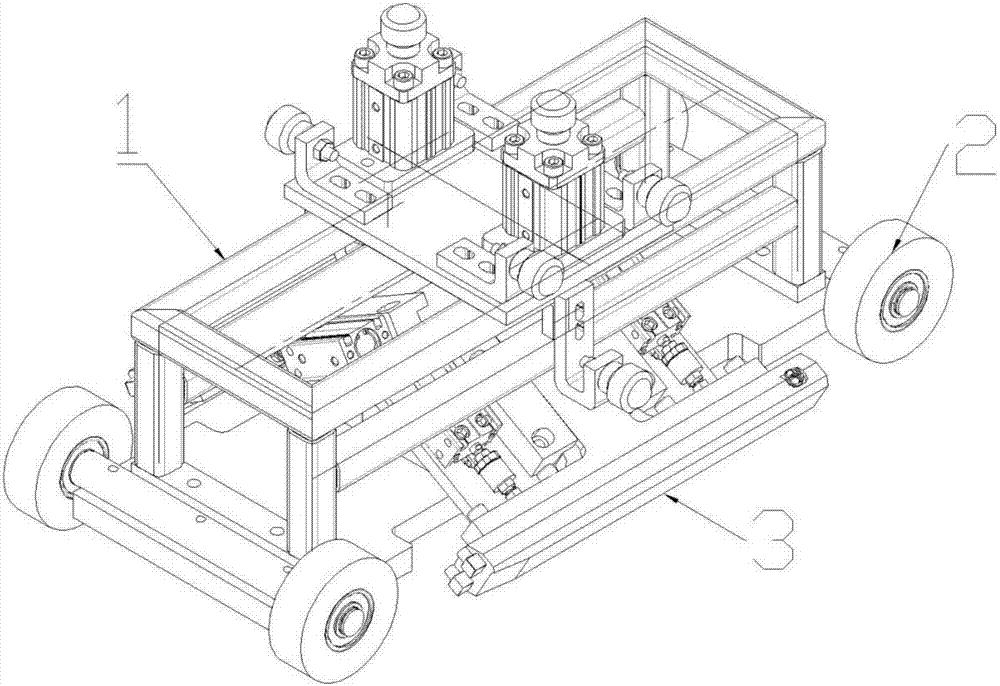

Image

Examples

Embodiment Construction

[0070] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0071] The invention provides a combined liner, which is used to shape the back of the longitudinal seam when welding the front of the longitudinal seam between the bridge deck unit and the U-shaped rib, including:

[0072] a soft pad for snuggling against the back of the longitudinal seam;

[0073] a hard pad for being in close contact with the surface of the soft pad away from the longitudinal seam;

[0074] Wherein, when the front side of the longitudinal seam is welded, the soft liner is partially melted, but the hard liner is not melted.

[0075] In the above technical solution, the orthotropic slab steel bridge is spliced by multiple bridge deck units, and each bridge deck unit needs to be welded with several U-shaped ribs, and a slender bridge must be formed between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com