Method for preparing metal-rhodium nanoparticle modified titanium dioxide nanotube array photocatalytic material

A nanoparticle modification, nanotube array technology, applied in metal/metal oxide/metal hydroxide catalysts, catalyst activation/preparation, chemical instruments and methods, etc., can solve the problem of reducing the photocatalytic efficiency of semiconductor materials and limiting solar energy. Light utilization, low quantum efficiency and other problems, to achieve the effect of good photocatalytic performance, short reaction time, and improved photocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

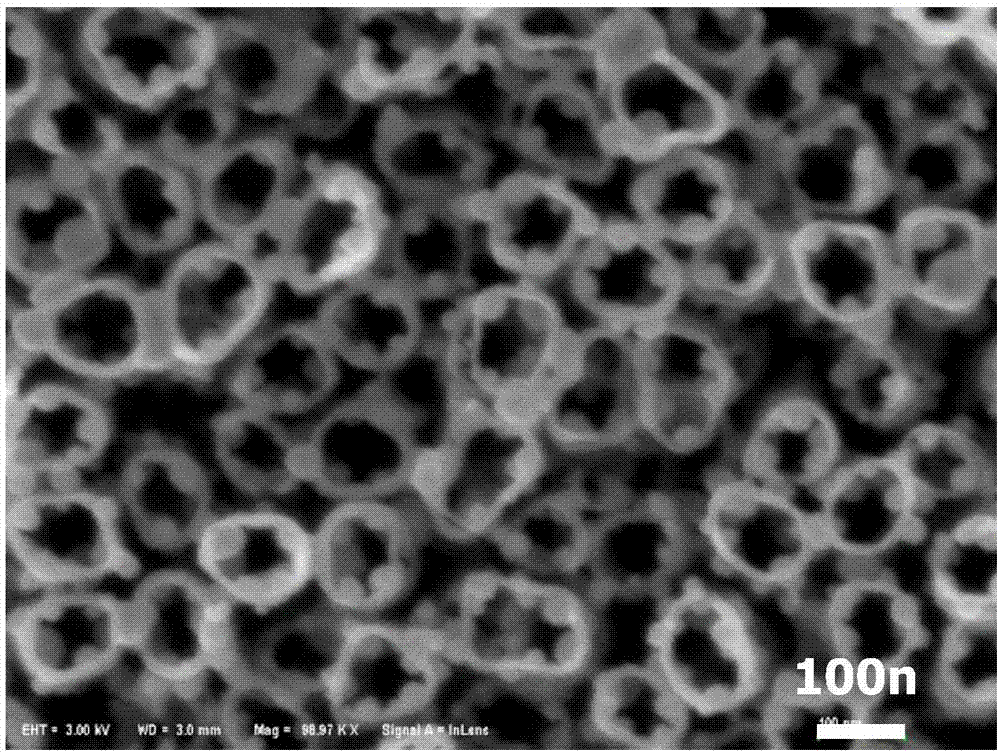

Image

Examples

Embodiment 1

[0034] Preparation of metal rhodium nanoparticles modified TiO 2 Nanotube array photocatalytic material, the steps are as follows:

[0035] Step 1: Mechanically polish the titanium sheet, and then perform ultrasonic cleaning.

[0036] Step 2, dissolving 1.76g of ammonium fluoride solute in a mixed solution consisting of 100mL and 200mL, and fully stirring for 2h to obtain an electrolyte used in the anodic oxidation reaction.

[0037] Step 3, then use the pretreated titanium sheet as the anode material, the platinum sheet as the cathode material, apply an applied voltage of 20v, and oxidize for 4h to obtain amorphous TiO 2 Nanotube array material, and then annealed to obtain anatase phase TiO 2 Nanotube Array Materials.

[0038] Step four, the TiO 2 The nanotube array material was placed in a rhodium nitrate solution with a concentration of 0.002mol / L, soaked at a constant temperature of 70°C for 8 hours, and washed 3 times with deionized water after soaking

[0039] Step ...

Embodiment 2

[0043] Preparation of metal rhodium nanoparticles modified TiO 2 Nanotube array photocatalytic material, the steps are as follows:

[0044] Step 1: Mechanically polish the titanium sheet, and then perform ultrasonic cleaning.

[0045] Step 2, dissolving 1.76g of ammonium fluoride solute in a mixed solution consisting of 100mL and 200mL, and fully stirring for 4h to obtain an electrolyte used in the anodic oxidation reaction.

[0046] Step 3, then use the pretreated titanium sheet as the anode material, the platinum sheet as the cathode material, apply an applied voltage of 20v, and oxidize for 4h to obtain amorphous TiO 2 Nanotube array material, and then annealed to obtain anatase phase TiO 2 Nanotube Array Materials.

[0047] Step four, the TiO 2 The nanotube array material was placed in a rhodium nitrate solution with a concentration of 0.003mol / L, soaked at a constant temperature of 70°C for 8 hours, and washed 3 times with deionized water after soaking

[0048] Step ...

Embodiment 3

[0051] Preparation of metal rhodium nanoparticles modified TiO 2 Nanotube array photocatalytic material, the steps are as follows:

[0052] Step 1: Mechanically polish the titanium sheet, and then perform ultrasonic cleaning.

[0053] Step 2, dissolving 1.76g of ammonium fluoride solute in a mixed solution consisting of 100mL and 200mL, and fully stirring for 2h to obtain an electrolyte used in the anodic oxidation reaction.

[0054] Step 3, then use the pretreated titanium sheet as the anode material, the platinum sheet as the cathode material, apply an applied voltage of 20v, and oxidize for 4h to obtain amorphous TiO 2 Nanotube array material, and then annealed to obtain anatase phase TiO 2 Nanotube Array Materials.

[0055] Step four, the TiO 2 The nanotube array material was placed in a rhodium nitrate solution with a concentration of 0.004mol / L, soaked at a constant temperature of 70°C for 8 hours, and washed 3 times with deionized water after soaking

[0056] Step ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com