High strength steel sheet and manufacturing method therefor

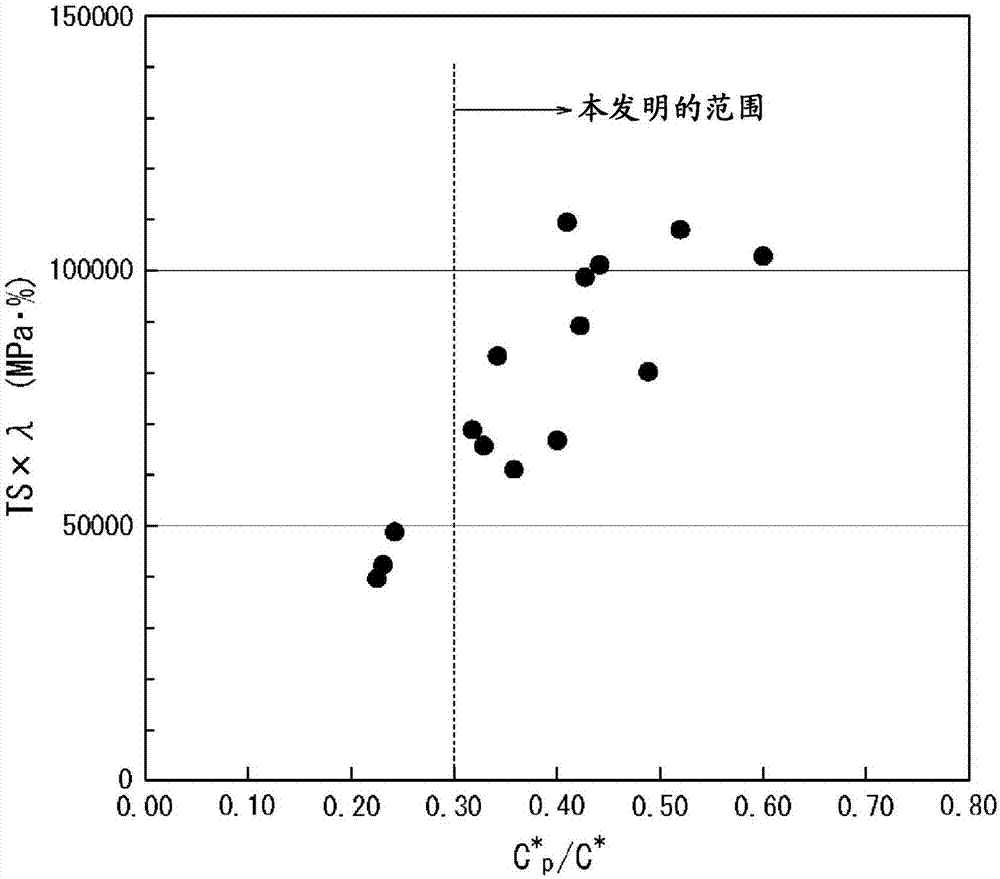

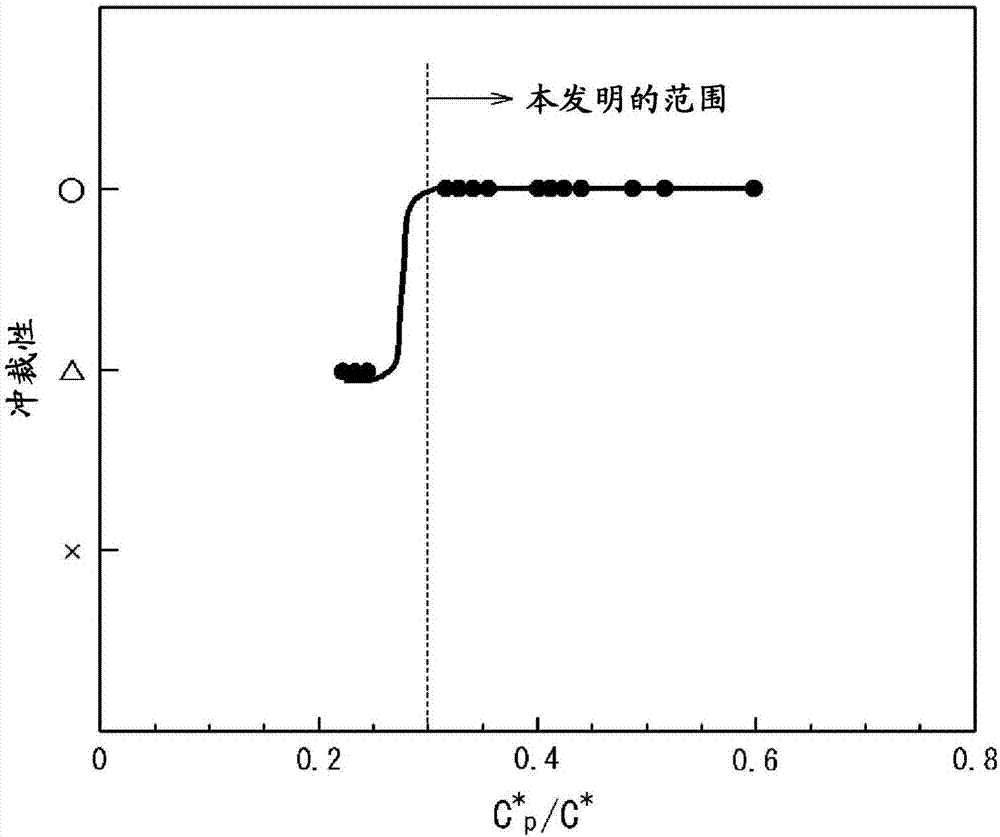

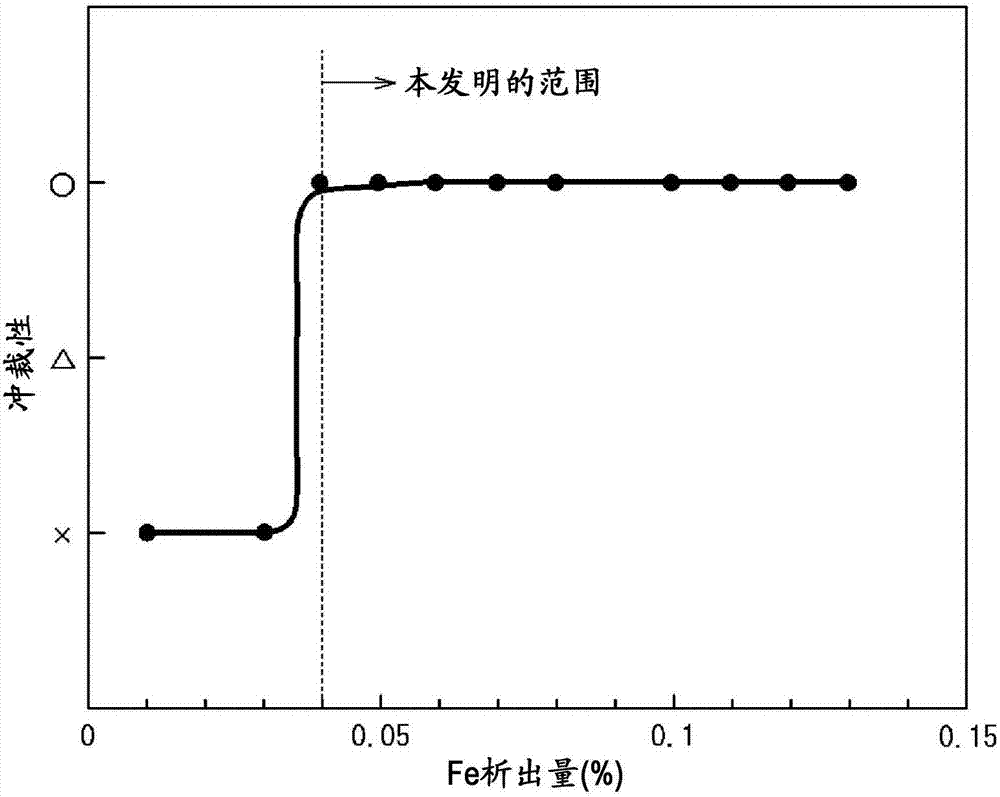

A high-strength steel plate and a manufacturing method technology, applied in manufacturing tools, furnaces, heat treatment equipment, etc., can solve problems such as insufficient punching properties, and achieve the effects of excellent punching properties and extended flange properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0152] Next, the present invention will be described more specifically based on examples. The following examples illustrate preferred examples of the present invention, and the present invention is not limited to these examples.

[0153] After heating the slabs with the composition shown in Table 1, they were hot-rolled under the conditions shown in Table 2 to manufacture hot-rolled steel sheets. In addition, some steel sheets were further processed at the thickness reduction rates described in Table 2. Test pieces were collected from each obtained hot-rolled steel sheet, and the structure and mechanical properties were evaluated by the methods described below. Table 3 shows the evaluation results of each item.

[0154] [Ferrite Area Fraction]

[0155] Follow the steps below to evaluate the ferrite area fraction. First, a steel plate thickness cross section parallel to the rolling direction of the steel plate was etched with nital to exhibit a microstructure, thereby obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com