Rotary nozzle for a high-pressure cleaning device

A rotating nozzle and high-pressure cleaning technology, which is applied in the direction of spraying devices and spraying devices with movable outlets, can solve the problems of fluid beam scattering and reduce the cleaning effect of fluid beams, and achieve the effect of easy modeling, low cost, and low manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

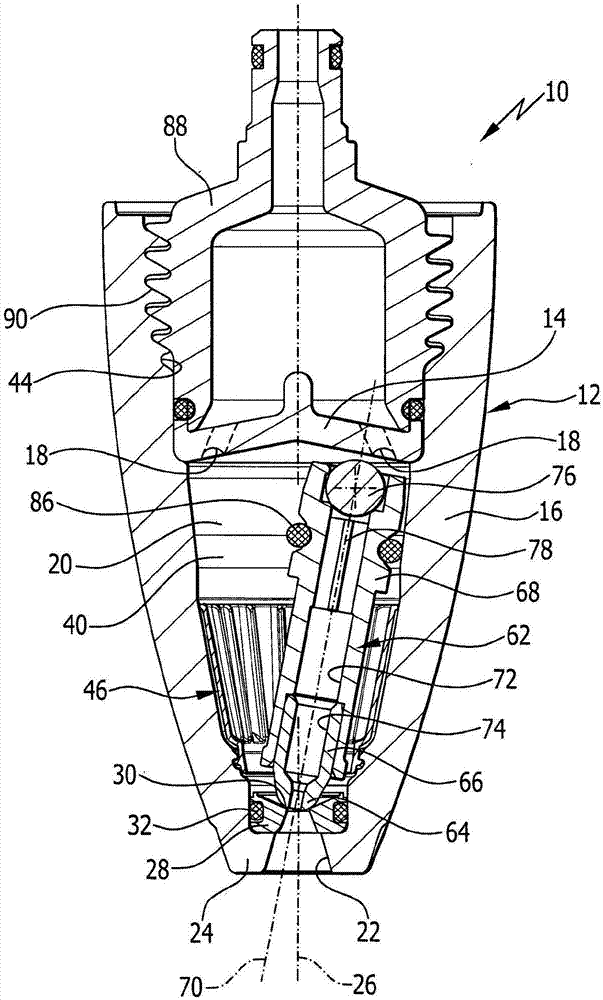

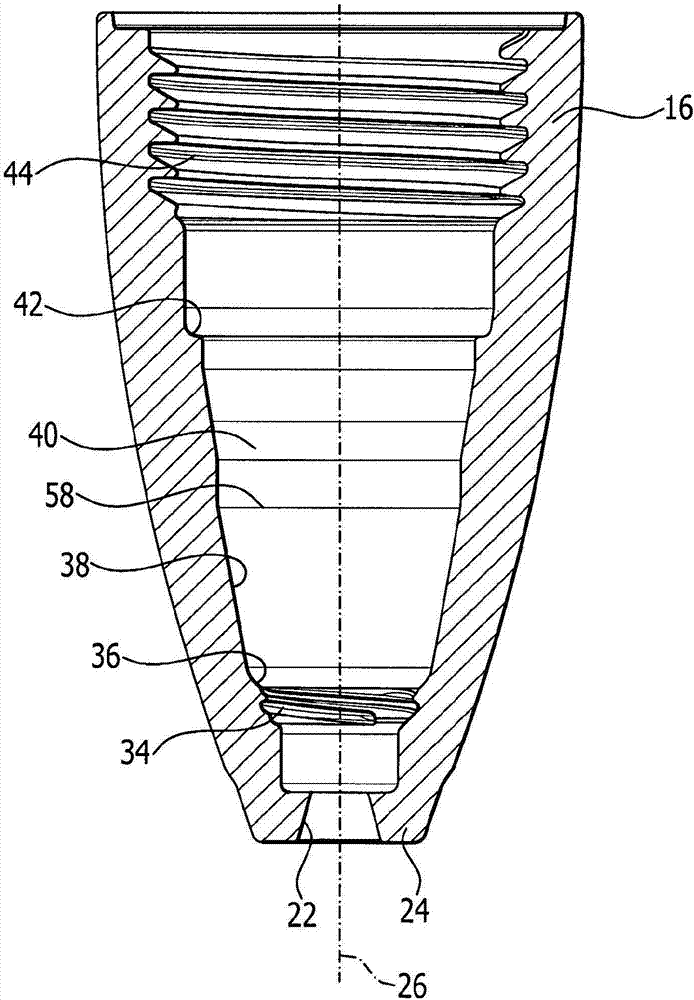

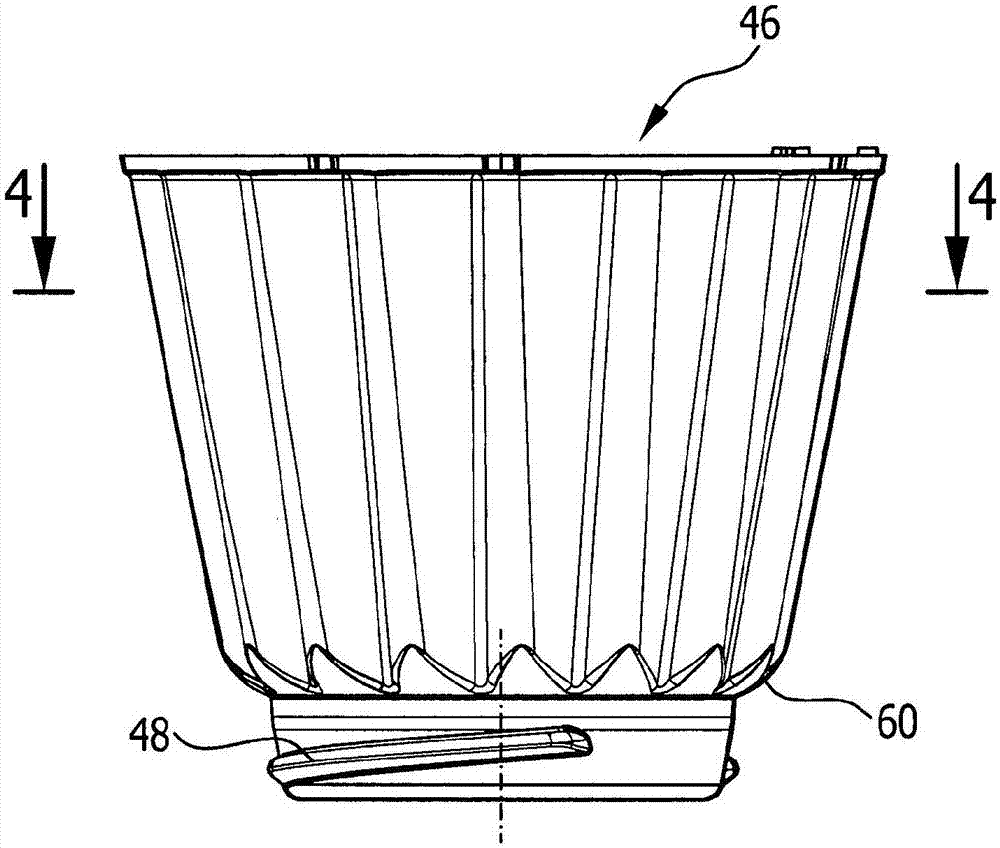

[0038] in Figure 1 to 4 A first advantageous embodiment of the rotary nozzle according to the invention is schematically shown in, which is designated by the reference number 10 as a whole. The rotating nozzle 10 has a housing 12 with a housing bottom 14 and a housing cover 16. The bottom 14 of the housing is designed to be disk-shaped and has a plurality of tangential inlets 18 which open into the inner chamber 20 of the housing 12. The inner chamber 20 is surrounded by the housing cover 16 and gradually narrows starting from the tangential inlet 18 to the outlet 22 arranged on the end wall 24 of the housing cover 16.

[0039] Via the tangential inlet 18, a fluid under pressure can be delivered to the inner chamber 20, which rotates around the housing longitudinal axis 26 in the inner chamber 20 and can escape from the housing 12 via the outlet 22.

[0040] In the inner chamber 20, a bearing in the form of a bearing ring 28 is arranged immediately upstream of the outlet 22, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com