Fast-liquid-injection high-infiltration long-service-life lithium battery and manufacturing method and mold thereof

A long-life, lithium-ion battery technology, applied in the manufacture of electrolyte batteries, secondary batteries, battery pack components, etc., can solve the problems of small free space, low static efficiency, time-consuming and labor-intensive problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with specific embodiments.

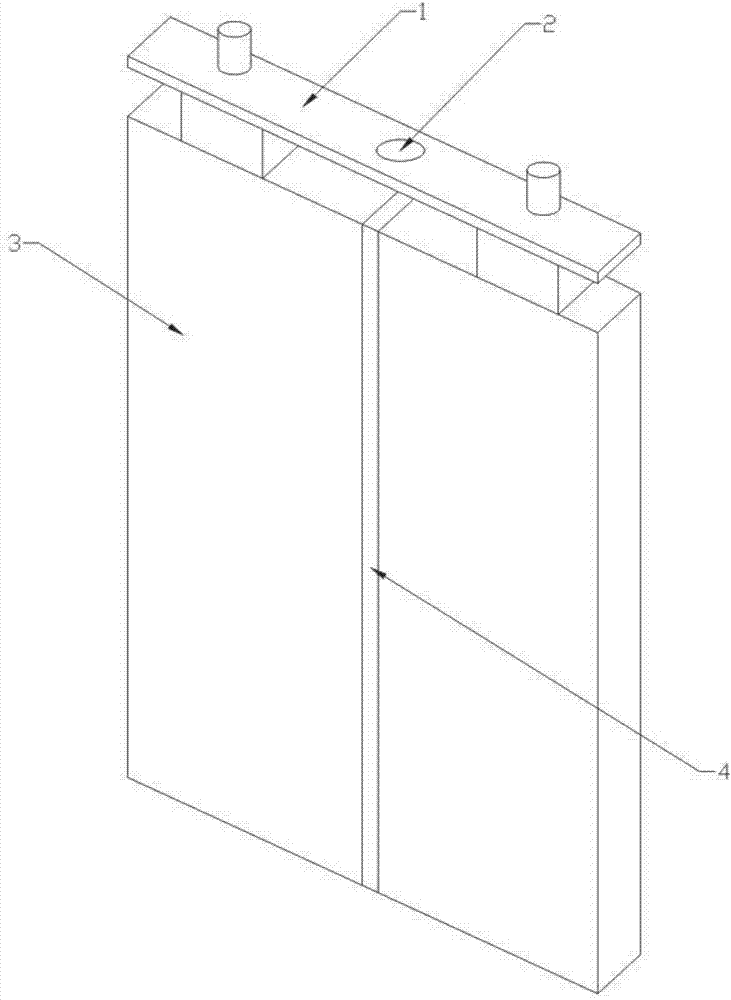

[0033] Such as figure 1 The invention provides a lithium battery with fast liquid injection, high infiltration and long life, which includes a casing and a top cover 1 for closing the opening of the casing. The top cover 1 is provided with a liquid injection port 2; Positive and negative electrode sheets 3; there is a diaphragm between the positive and negative electrode sheets 3; the positive and negative electrode sheets 3 are made of a substrate 31 and a slurry coating 32 coated on the surface of the substrate; wherein at least the positive electrode sheet 3 A groove 4 penetrating through the slurry coating 32 and reaching the substrate 31 is provided thereon. The grooves 4 penetrating through the slurry coating 32 and reaching the substrate 31 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com