Pillar insulator assembly and GIL system

A post insulator and insulator technology, which is applied in the field of gas-insulated metal-enclosed power transmission systems, can solve the problems of easy generation of debris, scratches on the inside of the cylinder and the floating part of the ground block, and inconvenient installation, so as to reduce the contact area, Reduce sliding resistance and facilitate installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

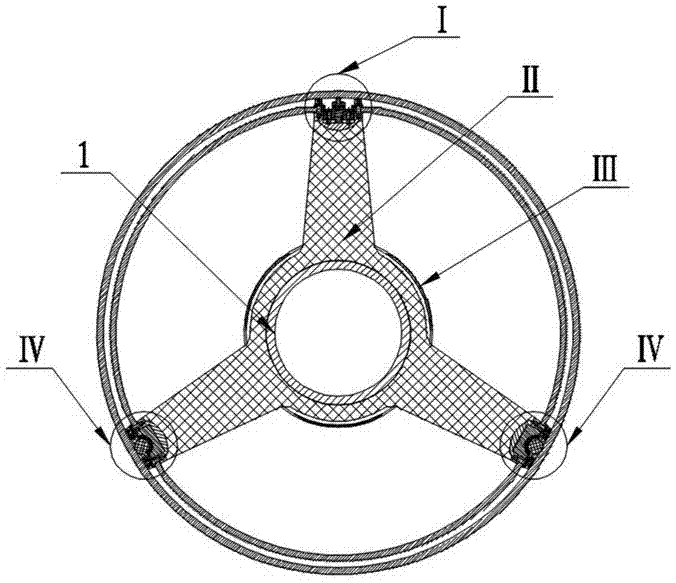

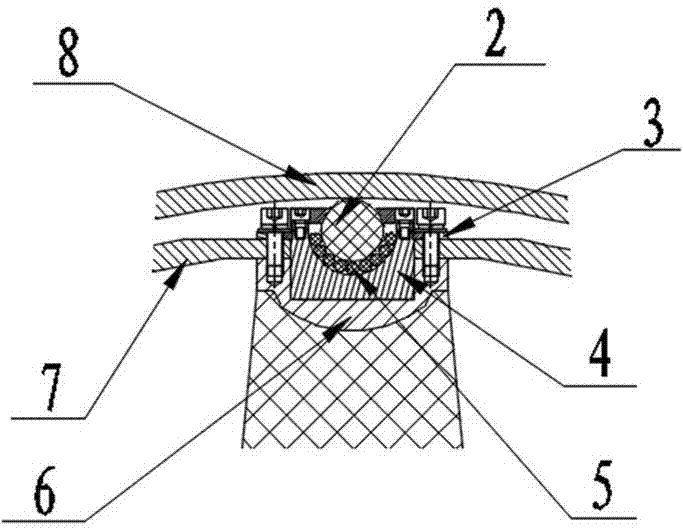

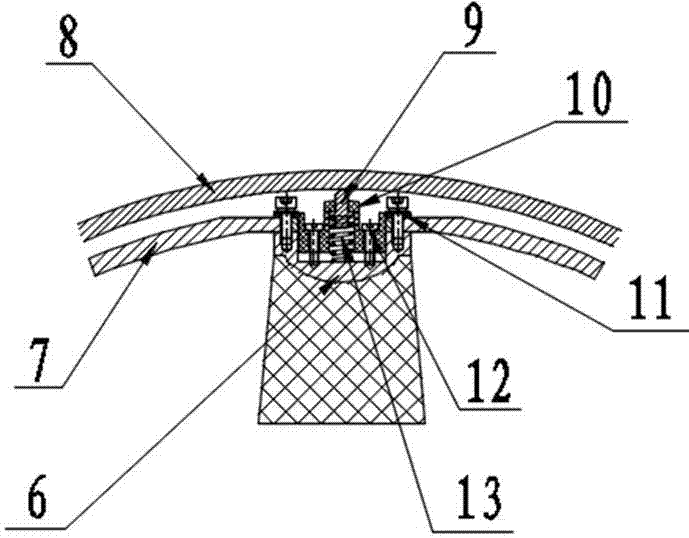

[0024] Specific embodiment one of the GIL system of the present invention, such as Figure 1 to Figure 3 As shown, it includes a cylinder body 8 that is sealed and connected in multiple sections, and a post insulator assembly is movably installed in the cylinder body 8 in the length direction of the cylinder body, that is, in the axial direction of the cylinder body. The post insulator assembly includes an insulator with three posts. The insulator includes an insulating castable body II. The insulating castable body II consists of a metal bushing 1, an insulating post cast on the outside of the metal bushing 1, and a Metal inserts6. The outer side of the insulating casting body II is also provided with a shielding part III, which can effectively reduce the problem of excessive electric field intensity along the surface caused by the concave-convex struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com