A metal smelting holding furnace

A heat preservation furnace and metal technology, applied in the direction of furnaces, crucible furnaces, furnace types, etc., can solve the problems of high thermal stress load on the surface of heating elements, short service life, high frequency of maintenance or replacement, etc., to prevent heat from being transferred to the shell, The effect of high heat utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

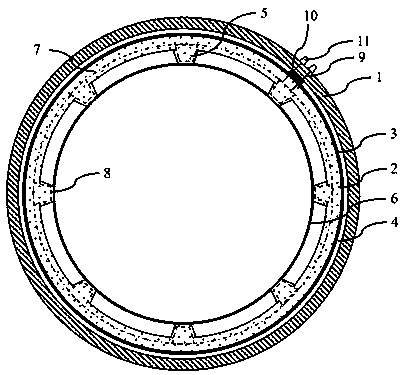

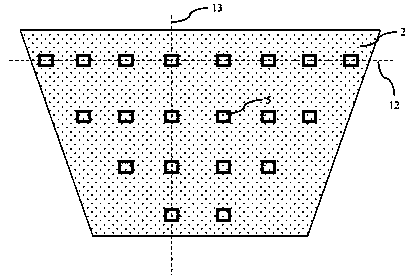

[0019] see figure 1 , the metal smelting and holding furnace of the present invention has a cylindrical furnace body structure, and the furnace body includes an outermost shell 1, a refractory brick layer 2 located in the shell 1 and an innermost crucible 6, and the shell There is a vacuum isolation cavity 4 between the body 1 and the refractory brick layer 2, the inner surface of the refractory brick layer 2 has a plurality of protrusions 5, and the plurality of protrusions 5 are in close contact with the crucible 6, the A first heating element 7 is arranged in the refractory brick layer 2, and the first heating element 7 is a spiral electric heating wire; each of the plurality of protrusions 5 has an independent second heating element 8, and the second The control circuits of the heating element 8 and the first heating element 7 are independent of each other; the outer side of the refractory brick layer 2 is also wrapped with a layer of fiber heat insulation layer 3 .

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com