Gear Pump

A gear pump and gear technology, applied in the direction of pumps, pump components, rotary piston pumps, etc., can solve the problems of unstable pump performance and reduced flow rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

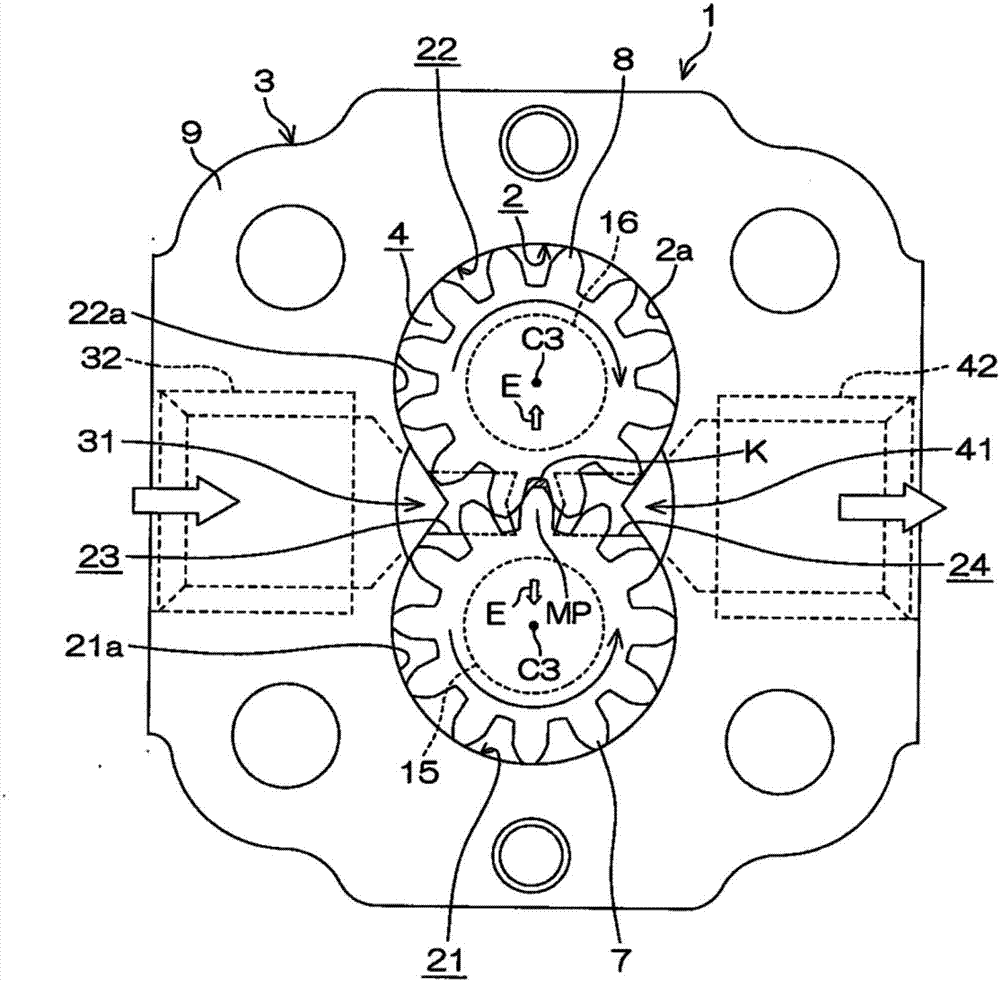

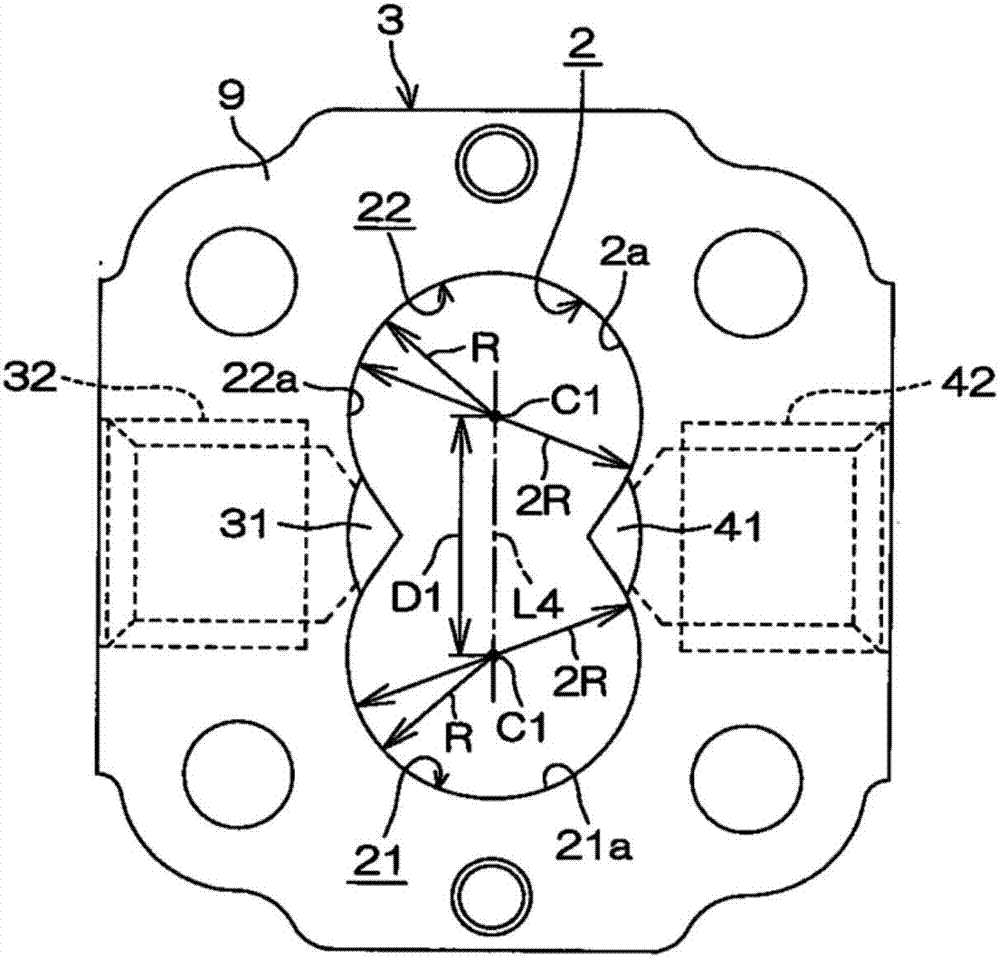

[0063] The amount of deviation ΔYa in the orthogonal direction V in Example 1 is much smaller than the amount ΔYc in the orthogonal direction V in Example 2 (ΔYa<ΔYc). Therefore, in Example 1, compared with Example 2, it is considered that due to the deviation of the dimensional tolerance of each component, even if the position of the second contact point P2 is deviated along the circumferential direction of the cylindrical holes 21 and 22, The variation in the position of the second contact point P2 in the orthogonal direction V can be further suppressed to be smaller, and the variation in performance can be further suppressed.

[0064] The present invention is not limited to the above-mentioned embodiment, although it is not shown in the figure, it can also be from any position, for example, as Figure 5A As shown, from the position of the second contact point P2 such that the first straight line L1 is perpendicular to the second straight line L2, the side having the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com