Method for improving glue uniformity in screw assembly dispensing process

A technology of uniformity and screws, applied in the field of assembly of screws and copper caps on tools, can solve the problems of easy accumulation of glue in a certain part of the screw, poor assembly effect, uneven quality, etc., so as to eliminate the glue residue on the shell and avoid inconsistency. , The effect of good assembly quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

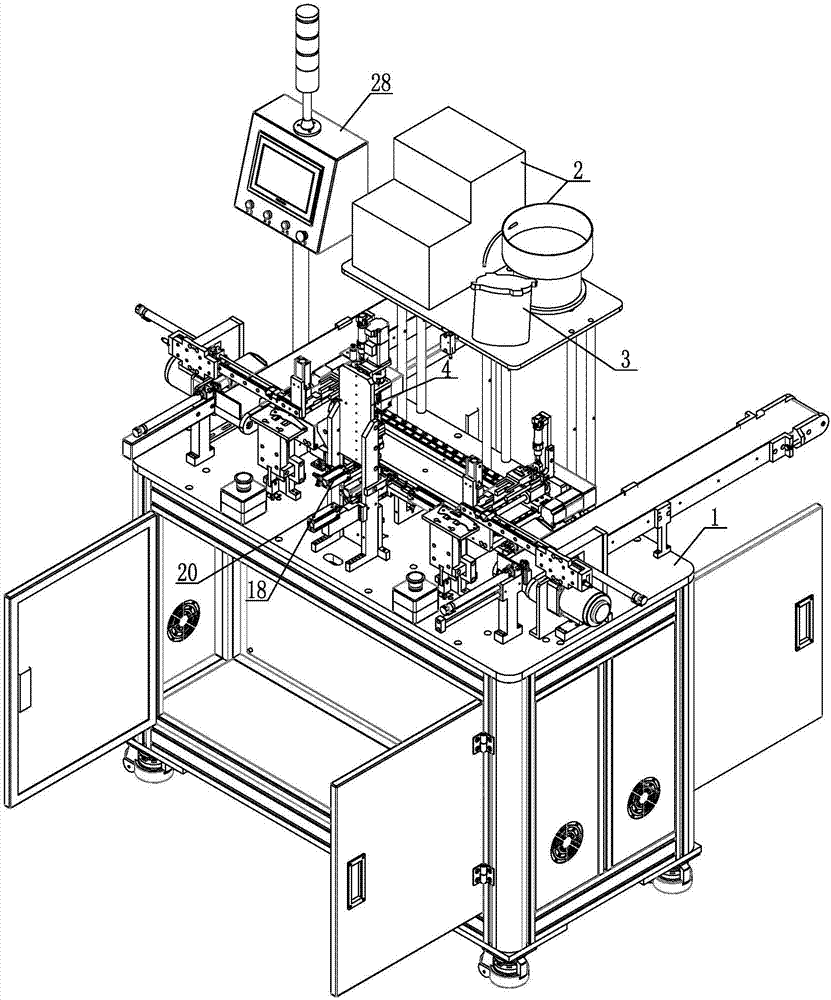

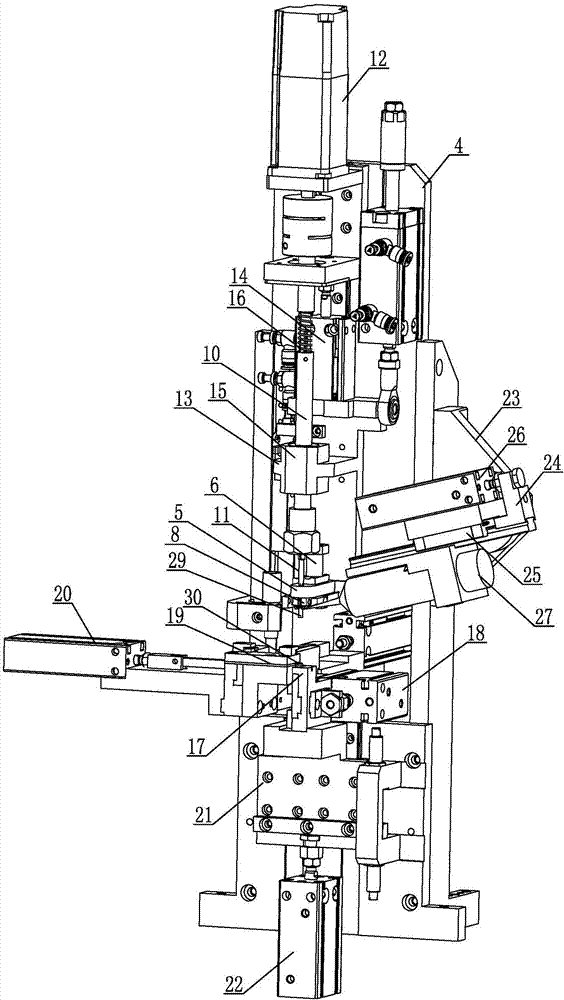

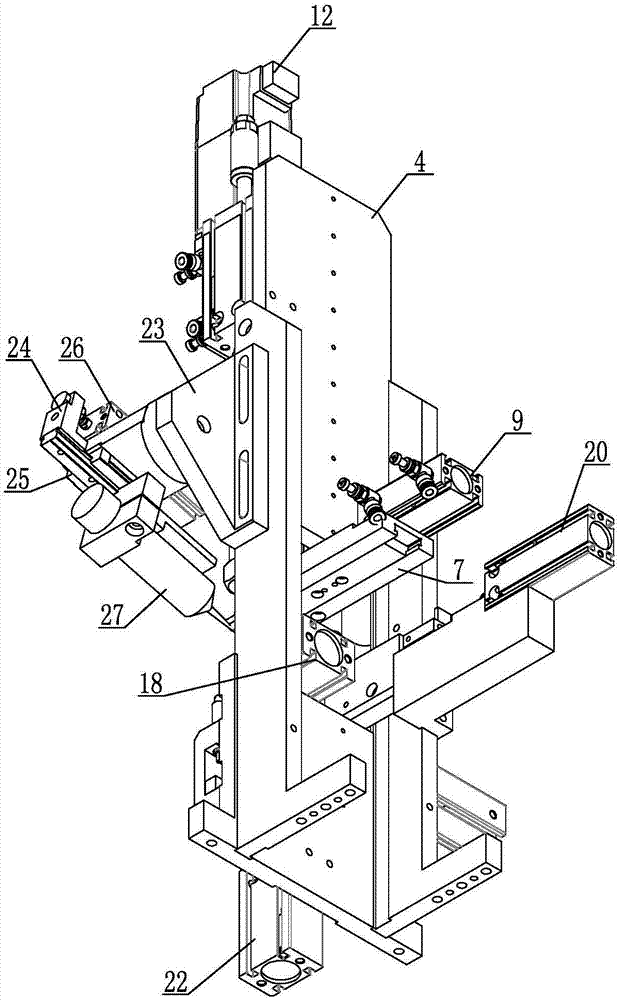

[0026] Such as figure 1 with figure 2 As shown, the method for improving the uniformity of glue in the dispensing process of screw assembly includes the following steps,

[0027] Step 1. Pour the screws 9 and copper caps 30 that need to be assembled into the vibrating plate 2 installed on the assembly platform 1 in batches, pour the assembly glue into the glue storage bin 3 installed on the assembly platform 1, The specific structure of the vibrating plate 2 is the common vibrating feeding equipment used by mechanical assembly companies to assemble the screws 29 and the copper caps 30 , and will not be described in detail here.

[0028] Step 2. In the assembly control device installed on the assembly platform 1, set the working parameters of the screw locking device and the glue dispensing device installed on the assembly platform 1. The specific method is as follows:

[0029] The parameters for using the locking screw device to rotate the screw on the assembly control devi...

Embodiment 2

[0033] The difference between this embodiment and Embodiment 1 is that the assembly parameters are changed according to the model of the tool assembly, that is, the setting parameter values of A, B, C, D, and E are adaptively adjusted, as follows Said:

[0034] This embodiment is used to assemble an irregular oval multifunctional knife shell with a length of 11.5cm and a width of 3.2cm. The time length is 0.2s, the dispensing volume is 0.02ml, and the dispensing action starts 0.2s later than the screw rotation action. After the screw 29 is in place, the assembly is carried out through the cooperation of the locking screw device and the dispensing device. After the equipment executes the processing parameters and the assembly is completed, the product is obtained. Through random inspection of the product, it is found that there are no problems such as missing glue dispensing and overflowing glue.

[0035] Whether it is the first embodiment or the second embodiment, the speci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com