Backflow smoke type moxa-moxibustion column and making method

A technology of moxibustion and moxa, which is applied in the direction of medical formulas, medical preparations containing active ingredients, plant raw materials, etc., can solve the problems of easy ash falling, inconvenient moxibustion, and great difference in curative effect, so as to improve utilization rate and increase The effect of curative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

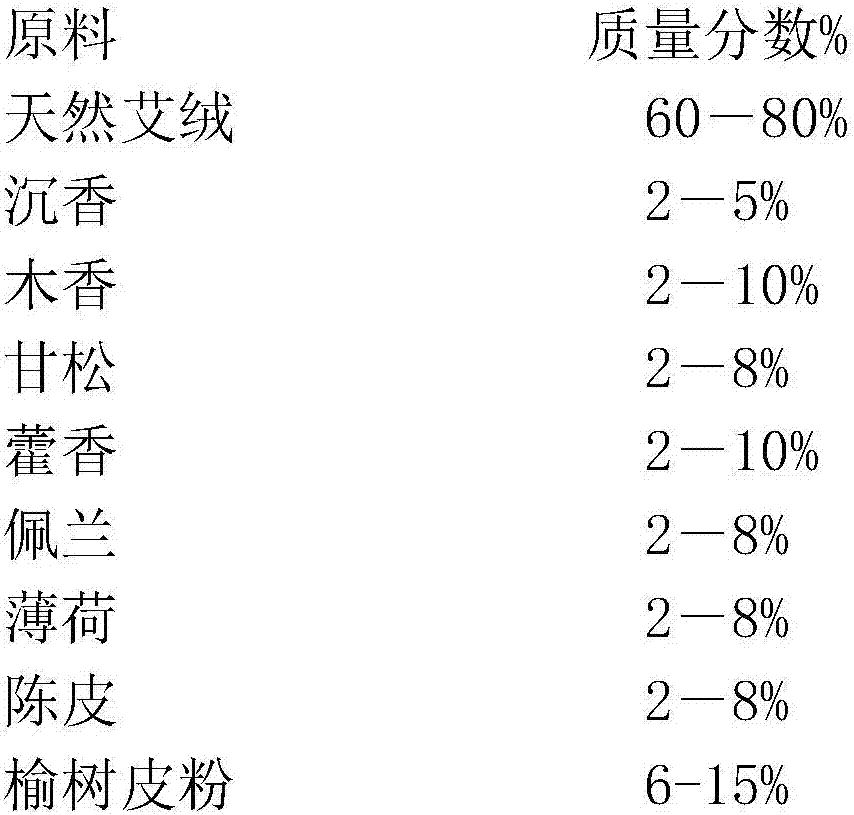

[0058] A backflow smoke type moxibustion column, which is made of the mass fraction of the following raw materials:

[0059]

[0060] A method for preparing a backflow smoke type moxibustion column, the steps are:

[0061] A. Weigh natural moxa, woody, agarwood, ageratum, perrin, nard pine, tangerine peel, mint, and elm bark powder in proportion.

[0062] B. Natural moxa, woody, agarwood, wrinkled wrinkle, perrin, nard pine, tangerine peel, mint, elm bark powder, mixed evenly to obtain a mixture;

[0063] C. Add tap water (5%-30%) to the mixture in step B, stir, and transfer into mud;

[0064] D. Knead it by hand or make it into a cone or bullet shape with a mold. The diameter of the bottom is between 0.5cm and 6.0cm, and the height is between 0.5cm and 8.0cm. A hole is punched in the middle of the bottom. The diameter of the hole can be adjusted The size adjustment of the moxibustion column is generally <1cm. The height of the hole is smaller than the height of the backf...

Embodiment 2

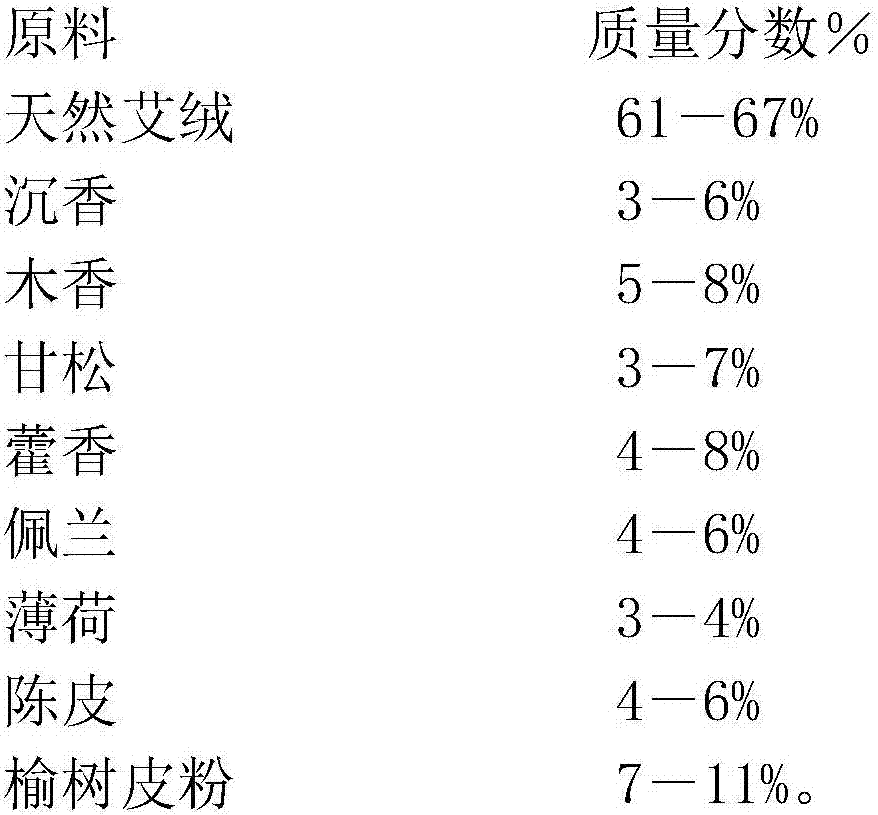

[0066] A backflow smoke type moxibustion column is composed as follows:

[0067] Natural moxa 65%, woody 5%, agarwood 3%, wrinkle 4%, nard pine 6%, perrin 4%, mint 3%, tangerine peel 2%, elm bark powder 8%, the above raw materials are weighed in proportion After that, mix well, add water to make mud, and make the main body of the moxibustion column conical in appearance, with a diameter of 4cm and a height of 5cm. The center of the moxibustion column is punched in the middle and dried before use. Long conical smoke backflow channel, the diameter of the smoke backflow channel is 0.8cm, and the height of the smoke backflow channel is 4.6cm. The moxibustion column made into moxibustion for patients with stomach deficiency and cold has an effective rate of 98%, which is 18% higher than that of the traditional moxibustion column.

Embodiment 3

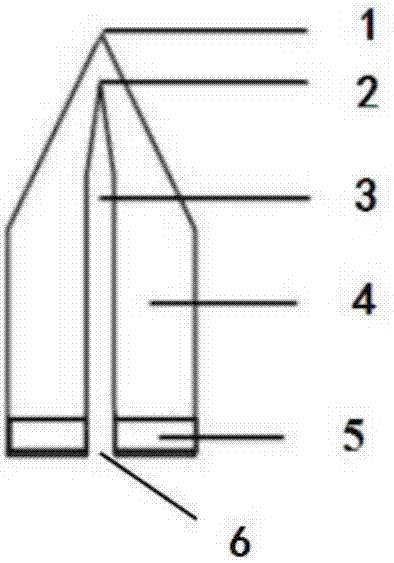

[0069] A smoke backflow type moxibustion column, which is composed of an ignition part 1, a smoke backflow point 2, a smoke backflow channel 3, a moxibustion column main body 4, a heat dissipation layer 5, and a smoke backflow outlet 6, and its connection relationship is: moxibustion The column main body 4 is respectively connected with the heat-dissipating heat insulation layer 5 and the ignition part 1. The moxibustion column main body 4 is provided with a smoke backflow point 2 and a smoke backflow channel 3, and the smoke backflow channel 3 is connected with the smoke backflow point 2 and the smoke backflow outlet 6 respectively. , the ignition site 1 is located at the highest point in the middle of the main body 4 of the moxibustion column, the smoke backflow point 2 is located directly below the ignition site 1, the smoke backflow point 2 is located in the middle of the main body 4 of the moxibustion column, and the smoke backflow channel 6 is located in the center of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bottom diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com