Clothes and manufacturing process of fabric made of clothes

A preparation process and clothing technology, applied in the field of clothing fabrics, can solve the problems of inability to guarantee the moisture removal performance of the fabric, affecting the appearance and touch, complex production process, etc., and achieve the effects of fast and timely test results, low test costs, and stable wrinkle structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

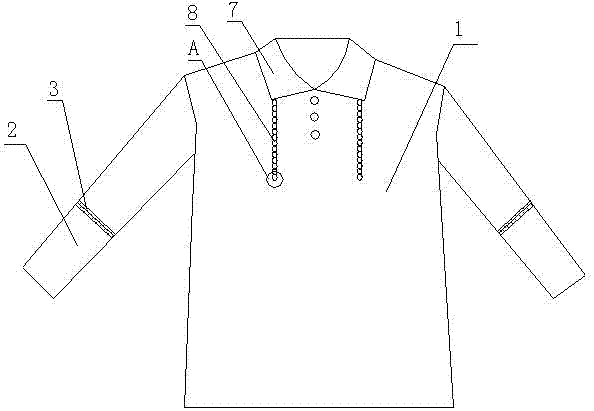

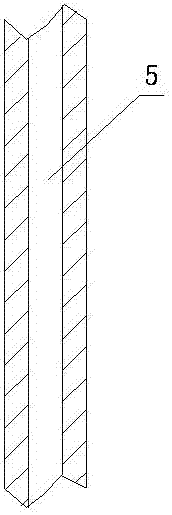

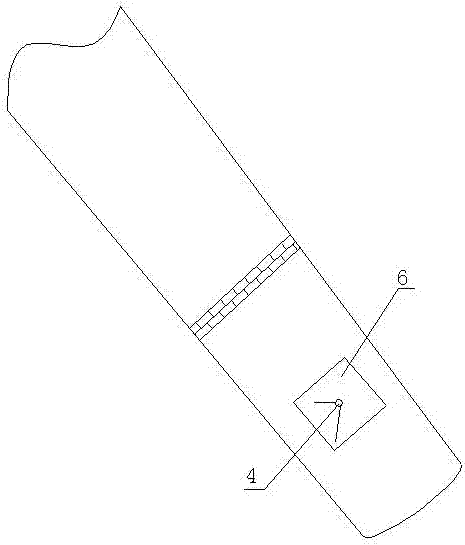

[0029] See Figure 1 to Figure 4 , The present invention relates to a garment, comprising a garment body 1 with two sleeves 2 on the garment body 1, the two sleeves 2 are connected to the outer garment body 1 by a zipper 3, and the sleeve 2 is at the front end The outer side of the arm has a hole and is provided with a transparent plastic 4, and an interlayer 5 is provided under the transparent plastic 4, and a clock 6 is placed in the interlayer 5.

[0030] The upper part of the clothes body 1 is the collar 7, and the clothes body 1 is also provided with a hanging chain 8. The hanging chain 8 has two sections, one end of each section is fixed to the collar 7 and the other end is provided with a chain buckle 9. The chain buckle 9 is similar to a key chain, which is used to buckle with the temples of the reading glasses to fix the reading glasses.

[0031] The fabric of the garment is a double-layer fabric interwoven with one set of warp yarns and two sets of weft yarns. The surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com