A fully assembled pig house

A prefabricated, fully assembled technology, applied in animal houses, applications, animal husbandry, etc., can solve the problems of large pollution in the construction process, long construction period, low construction level, etc., to reduce on-site construction operations and construction time, Construction efficiency and quality improvement, the effect of reducing drilling construction work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

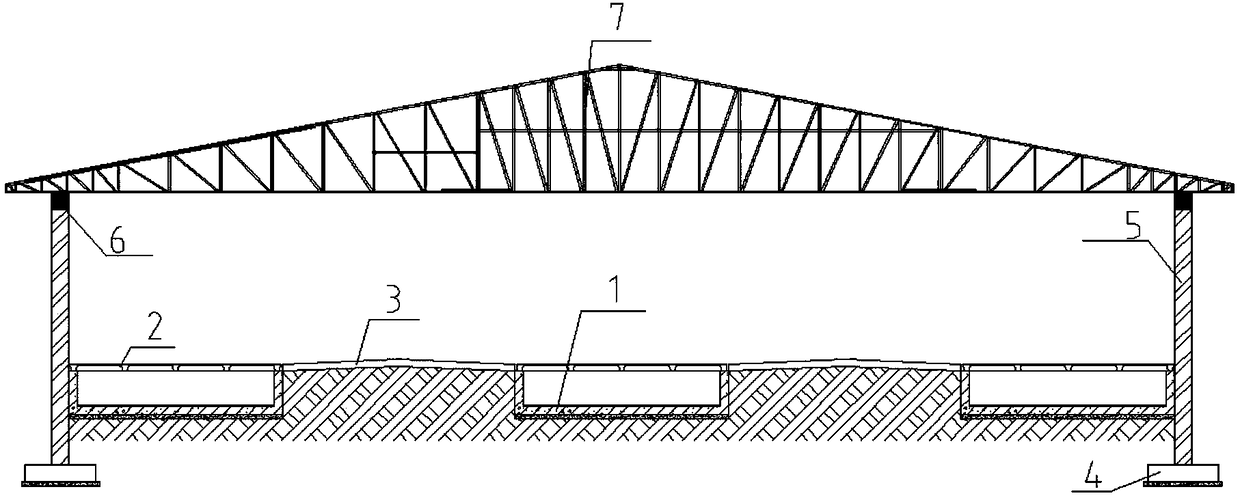

[0050] Such as Figure 1~4 As shown, in a preferred embodiment of the present invention, the fully-assembled pig house includes a prefabricated manure ditch system and a prefabricated building system enclosing the prefabricated manure ditch system.

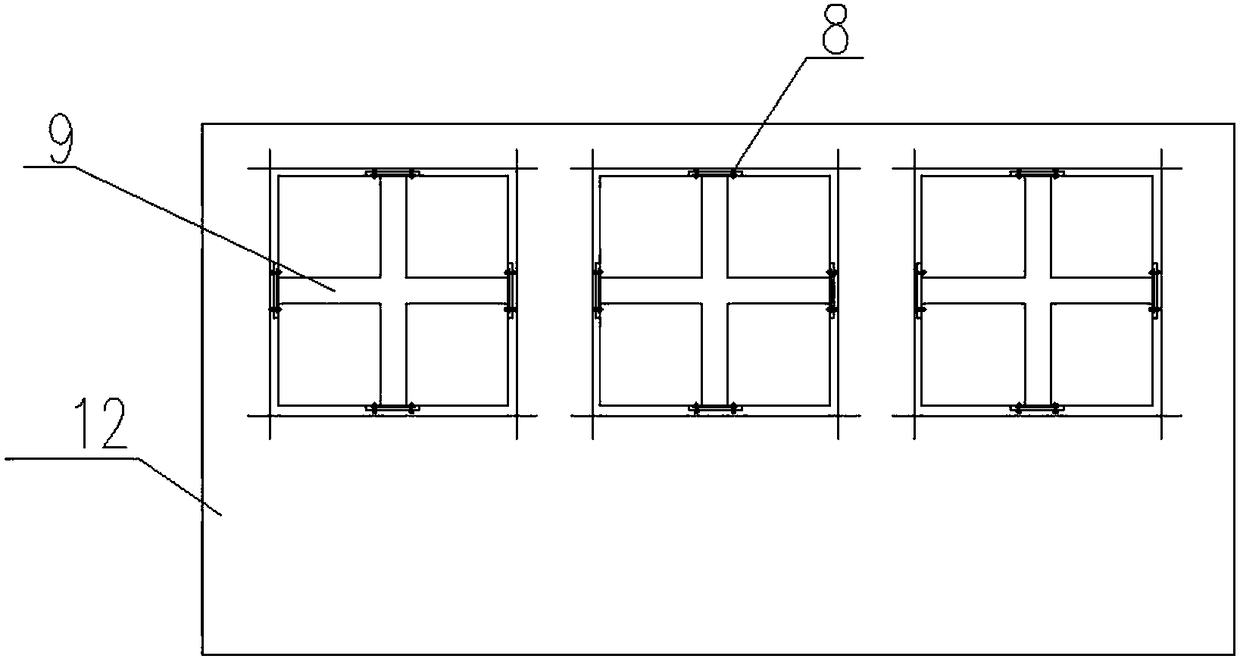

[0051] Among them, the prefabricated manure ditch system includes three parallel prefabricated manure ditches 1 buried under the indoor floor of the pig house and arranged along the long axis of the pig house, and each of the prefabricated manure ditch 1 covered The prefabricated slatted board 2 is flush with the indoor floor 3 of the piggery. The aisle of the pig house is between the adjacent prefabricated manure ditch 1, and the aisle is a slope structure with a high middle and low sides, and the slope is 2-5%.

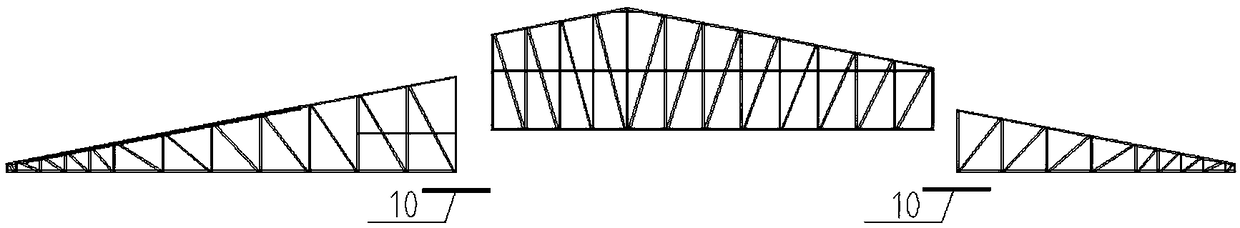

[0052] The prefabricated building system includes prefabricated concrete foundation 4, prefabricated prefabricated column 5, prefabricated beam 6, prefabricated roof truss and prefabricated prefabricated slab. The pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com