Double-side imprinted conductive film, manufacturing method thereof, circuit board and touch module

A production method and technology of conductive film, applied in the directions of printed circuit, printed circuit manufacturing, transfer printing method, etc., can solve the problems of complex process, low production yield, limited transparent conductive film, etc., and achieve high transmittance and good yield. High and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

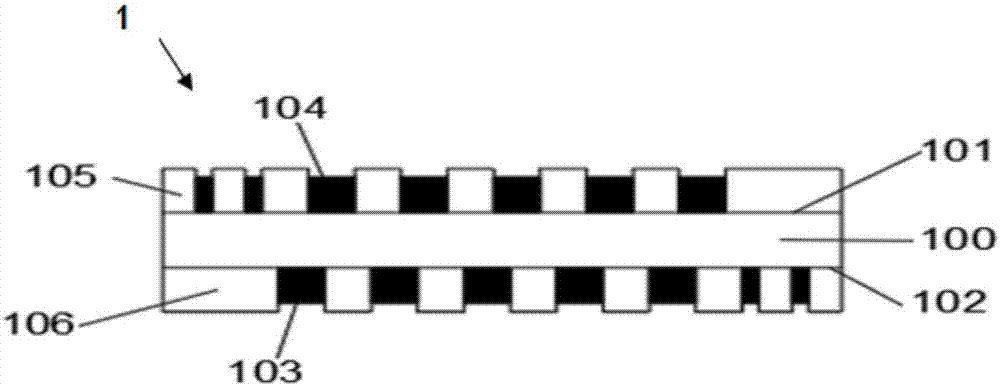

[0026] See figure 1 , the double-sided embossed conductive film 1 shown in a preferred embodiment of the present invention (embodiment 1) includes a transparent substrate 100 having a first surface 101 and a second surface 102 oppositely arranged, and the transparent substrate 100 A first conductive layer 104 and a first dielectric layer 105 are disposed on the first surface 101 , and a second conductive layer 103 and a second dielectric layer 106 are disposed on the second surface 102 of the transparent substrate 100 . The first conductive layer 104 is the input wiring layer, the second conductive layer 103 is the output wiring layer, and the first dielectric layer 105 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com