Composite frame type low-voltage bus slot and preparation method thereof

A technology of composite frame and busway, which is applied in the direction of assembly/disassembly of semi-enclosed busbar devices and contact pieces, which can solve the problems of high temperature and humidity requirements in the production environment, bubbles and structural defects of insulating materials, and low mechanical strength of the busway and other problems, to achieve the effect of good bending and torsion resistance, low internal bubble content, and short process cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

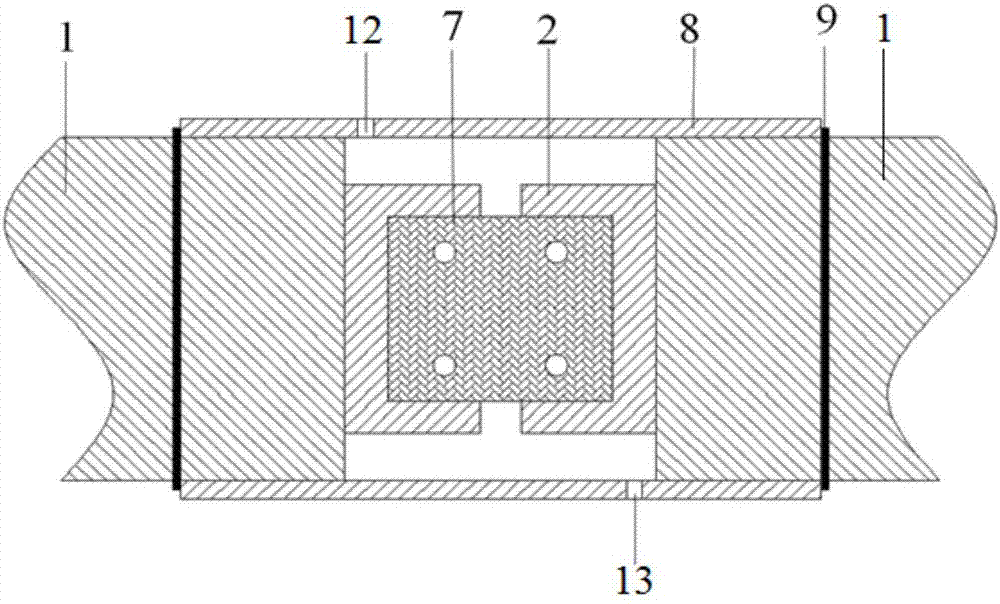

[0037] The present invention is a composite frame type low-voltage bus duct, such as figure 1 As shown, it includes several busbar straight section supports, and the joint section is connected between every two adjacent busbar straight section supports.

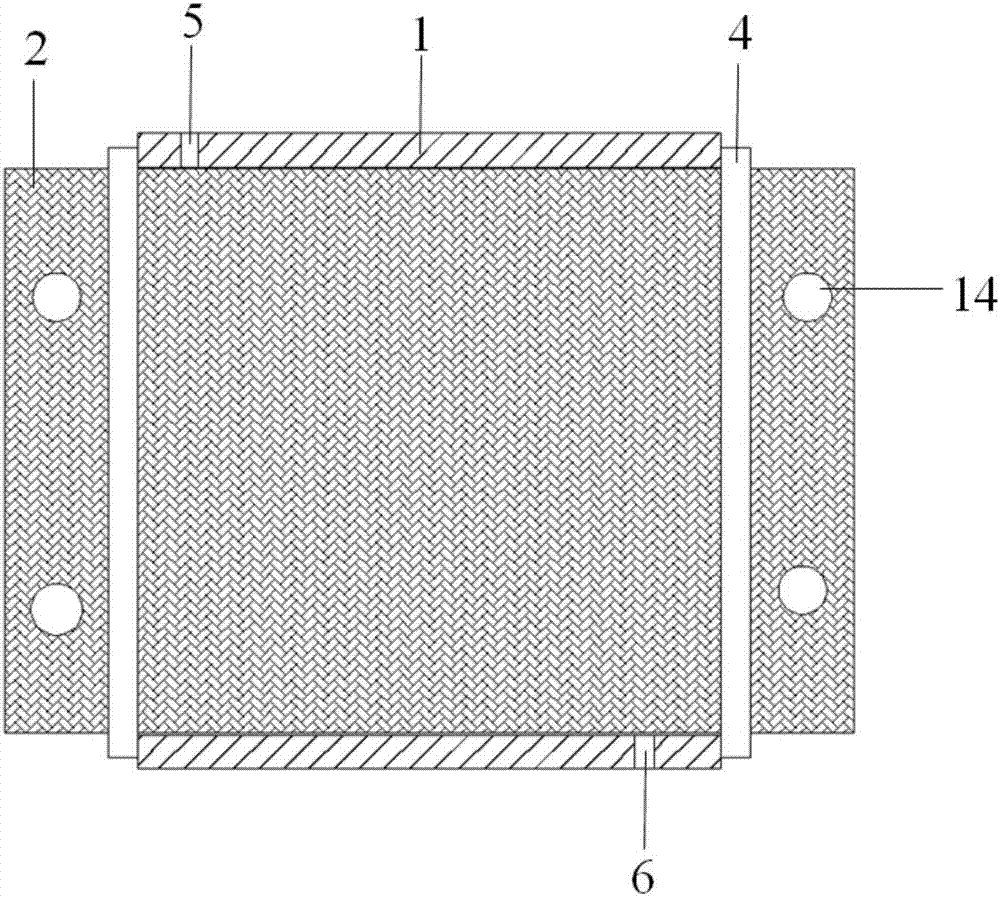

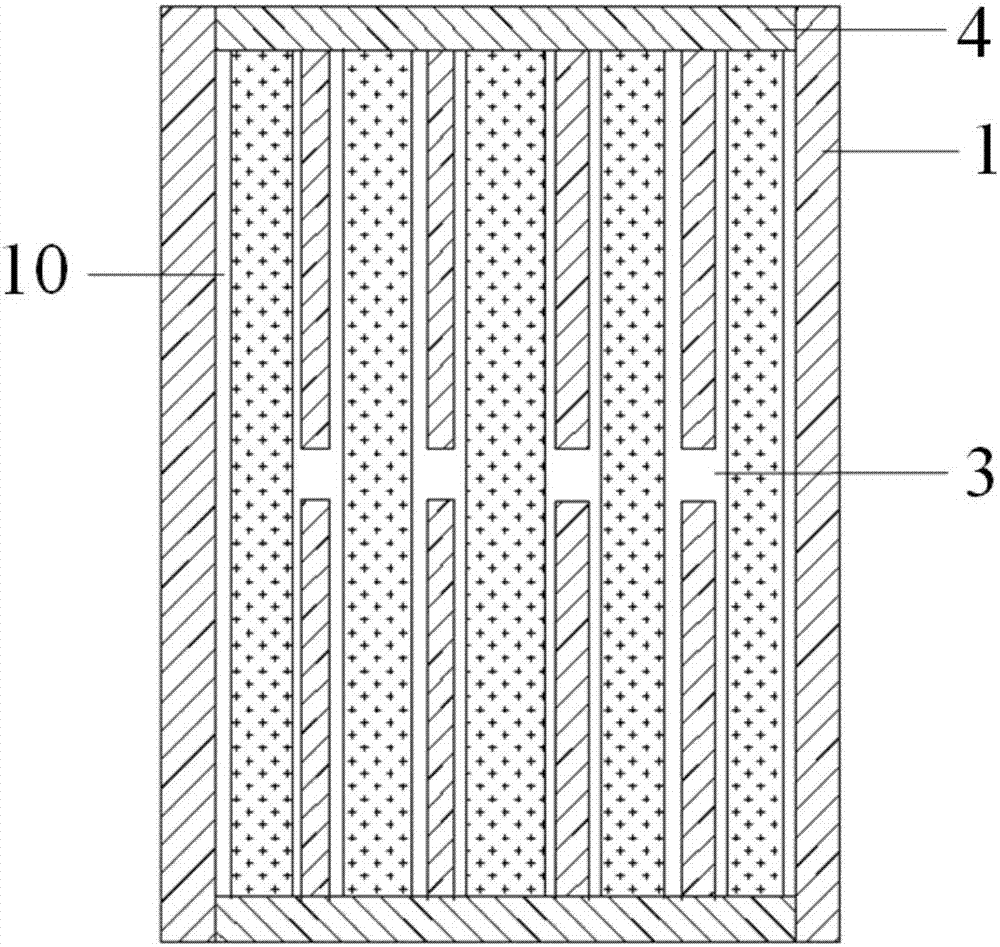

[0038] Such as figure 2 As shown, the straight section support includes an insulating sheath 1 for the straight section of the busbar. The insulating sheath 1 for the straight section of the busbar is prefabricated by pultrusion, molding or vacuum impregnation. The insulating sheath 1 for the straight section of the busbar is rectangular and cylindrical. The two opposite sides of the sheath 1 are provided with 3 to 5 grooves 10, such as image 3 As shown, and the two side grooves 10 are opposite, a conductor 2 is arranged between every two opposite grooves 10, and the conductor 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com