End-fire planar circularly polarized antenna

A circularly polarized antenna, plane technology, applied in antennas, resonant antennas, electrical short antennas, etc., can solve the problems of low gain and narrow bandwidth, and achieve the effect of high gain, wide bandwidth and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

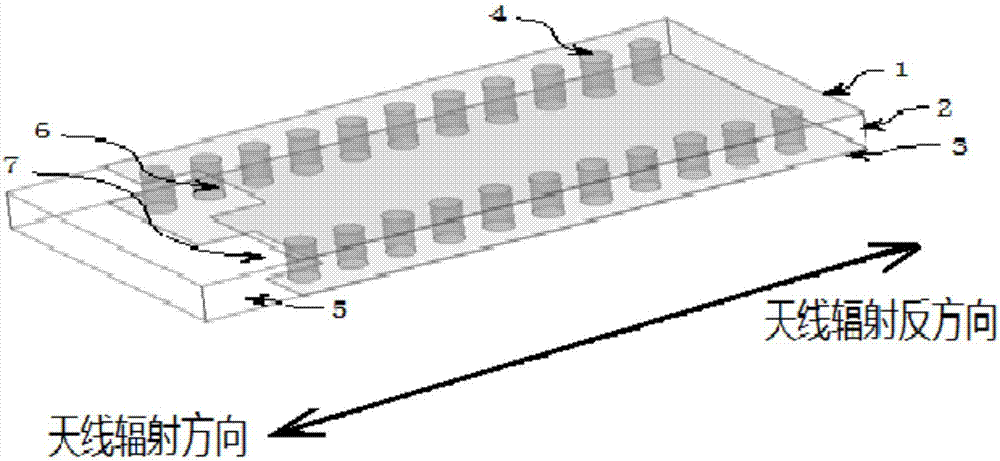

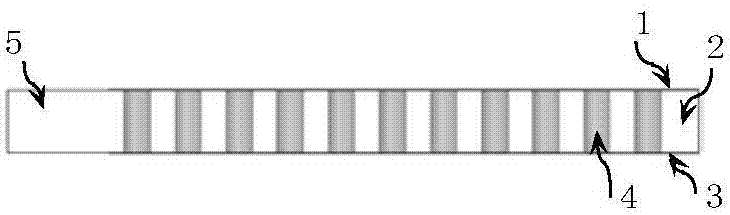

[0046] Such as figure 1 As shown, it is a three-dimensional structure diagram of the antenna described in Embodiment 1 of the present invention. The dielectric layer 2 can be made of Rogers5880, the thickness of the dielectric layer can be 1.575mm, and the printed circuit board PCB technology is used on the upper surface and the lower surface of the dielectric layer A layer of metal is respectively plated to form the upper surface metal layer 1 and the lower surface metal layer 3. The thickness of the metal layer can be 0.035mm, and the metal can be copper. There is a via hole on one side, and metal is coated on the inner wall of the via hole to form a via hole 4. The via hole electrically connects the upper surface metal layer and the lower surface metal layer. The diameter of the via hole is 0.7mm, and the distance between the via holes on the same side The distance between the centers of the through holes on both sides is 1.3mm. The through holes, the metal layer on the upp...

Embodiment 2

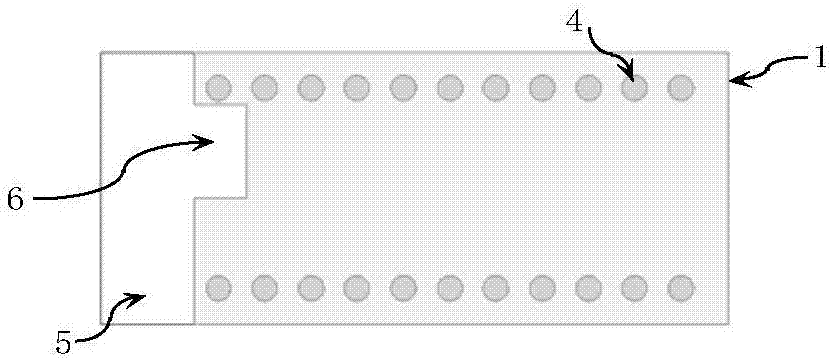

[0049] Such as Figure 5 Shown is a three-dimensional structure diagram of the antenna described in Embodiment 2 of the present invention. Dielectric layer 11, the selected material can be Rogers5880, the thickness of the dielectric layer can be 1.575mm, utilize PCB technology to coat one layer of metal layer 10, metal layer 12 respectively on the upper bottom surface and the lower bottom surface of the dielectric layer, the thickness of the metal layer can be The metal is 0.035mm, and the metal can be copper. On the whole composed of the upper surface metal layer, the lower surface metal layer and the middle dielectric layer, via holes are punched out using PCB technology along the two sides parallel to the radiation direction of the antenna. On the inner wall of the via hole Metal is coated on top to form a via hole 13, which allows the metal layer 10 and the metal layer 12 to maintain electrical connection. The upper surface metal layer, the lower surface metal layer, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com