Touch module, electronic device and pressure calibration method

A touch module and pressure technology, applied in electrical digital data processing, instruments, calculations, etc., can solve the problems affecting the detection accuracy of the pressure touch sensor and the deformation of the touch screen, so as to avoid false responses and ensure the detection accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Reference will now be made in detail to the exemplary embodiments, examples of which are illustrated in the accompanying drawings. When the following description refers to the accompanying drawings, the same numerals in different drawings refer to the same or similar elements unless otherwise indicated. The implementations described in the following exemplary examples do not represent all implementations consistent with the present disclosure. Rather, they are merely examples consistent with aspects of the disclosure as recited in the appended claims.

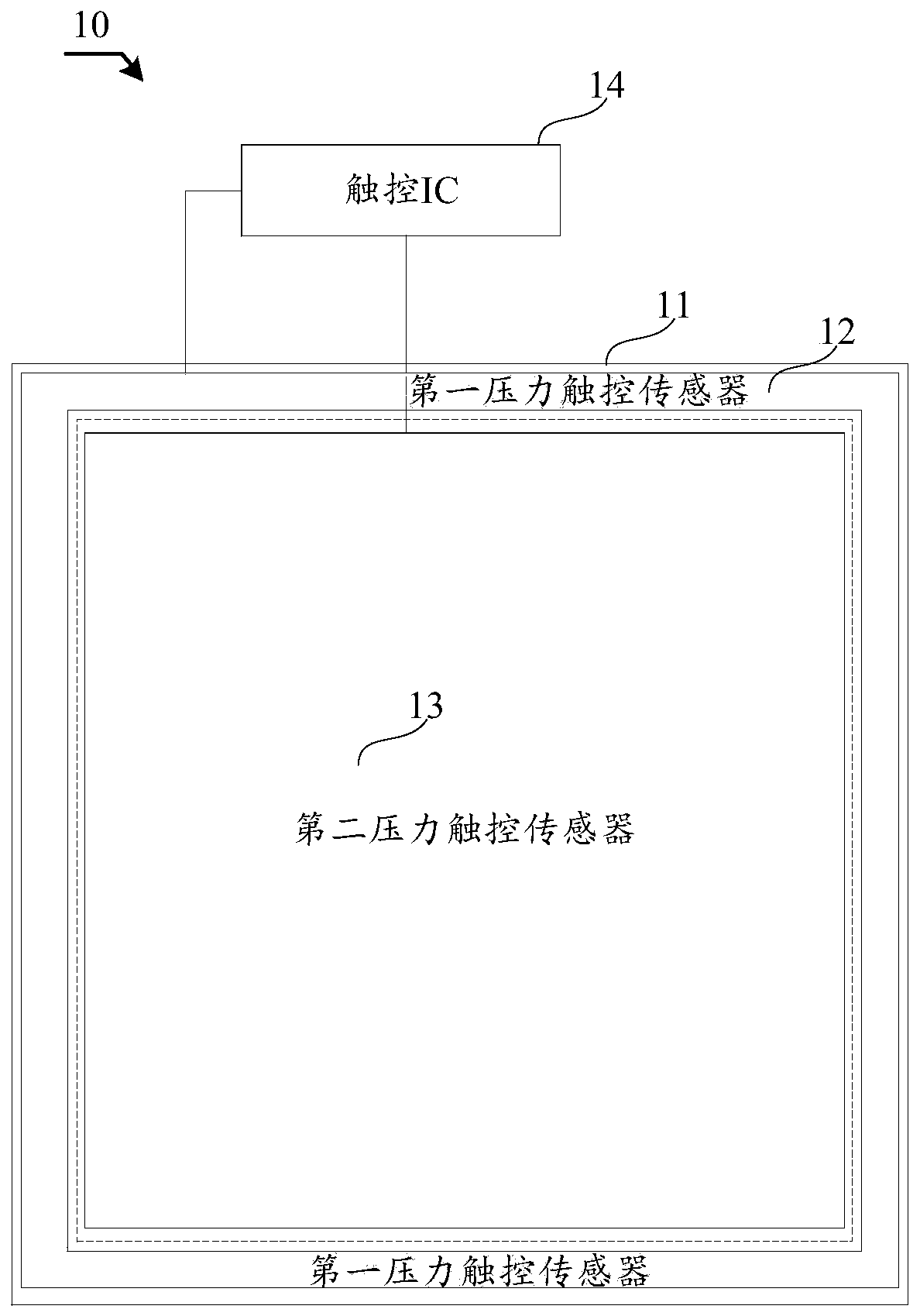

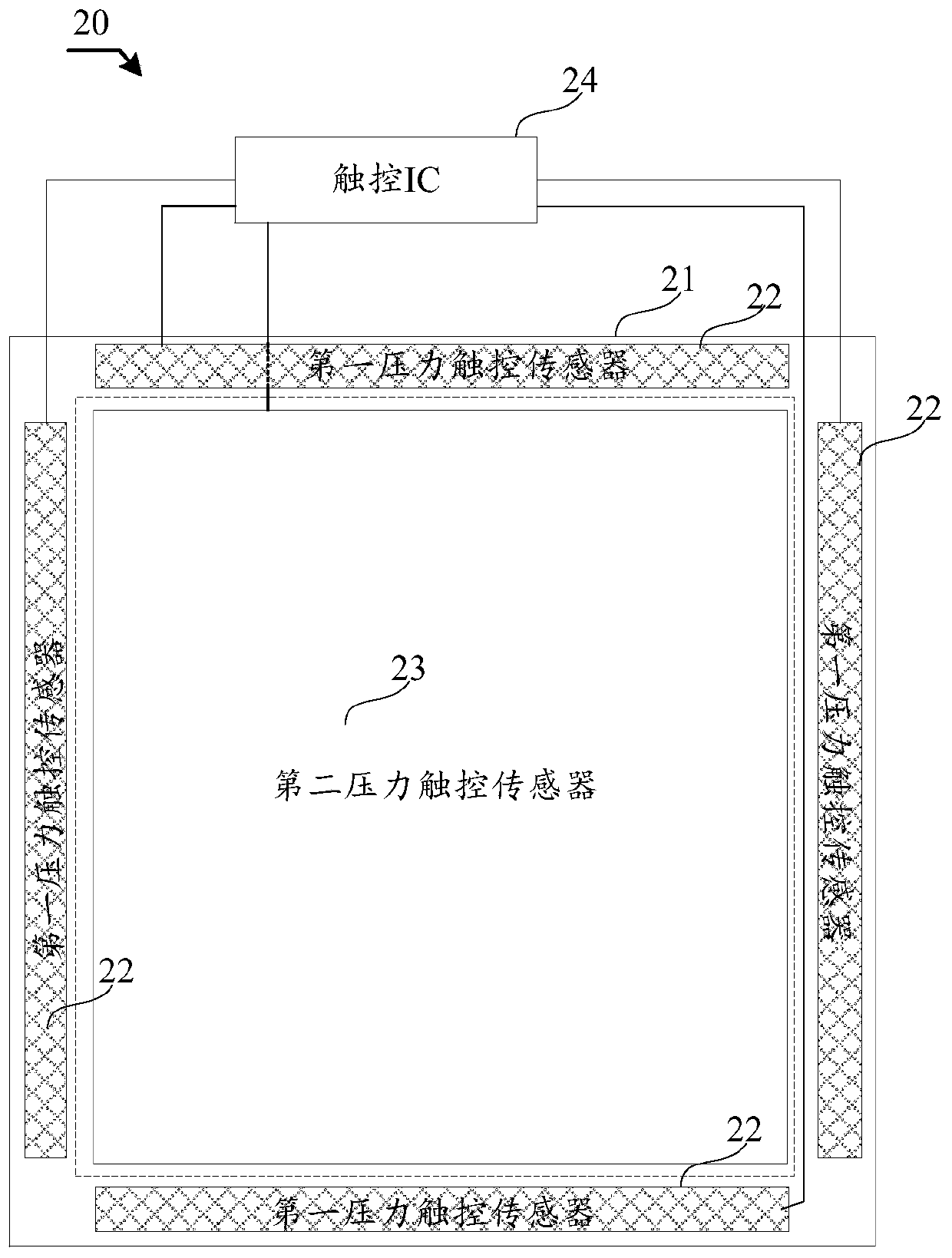

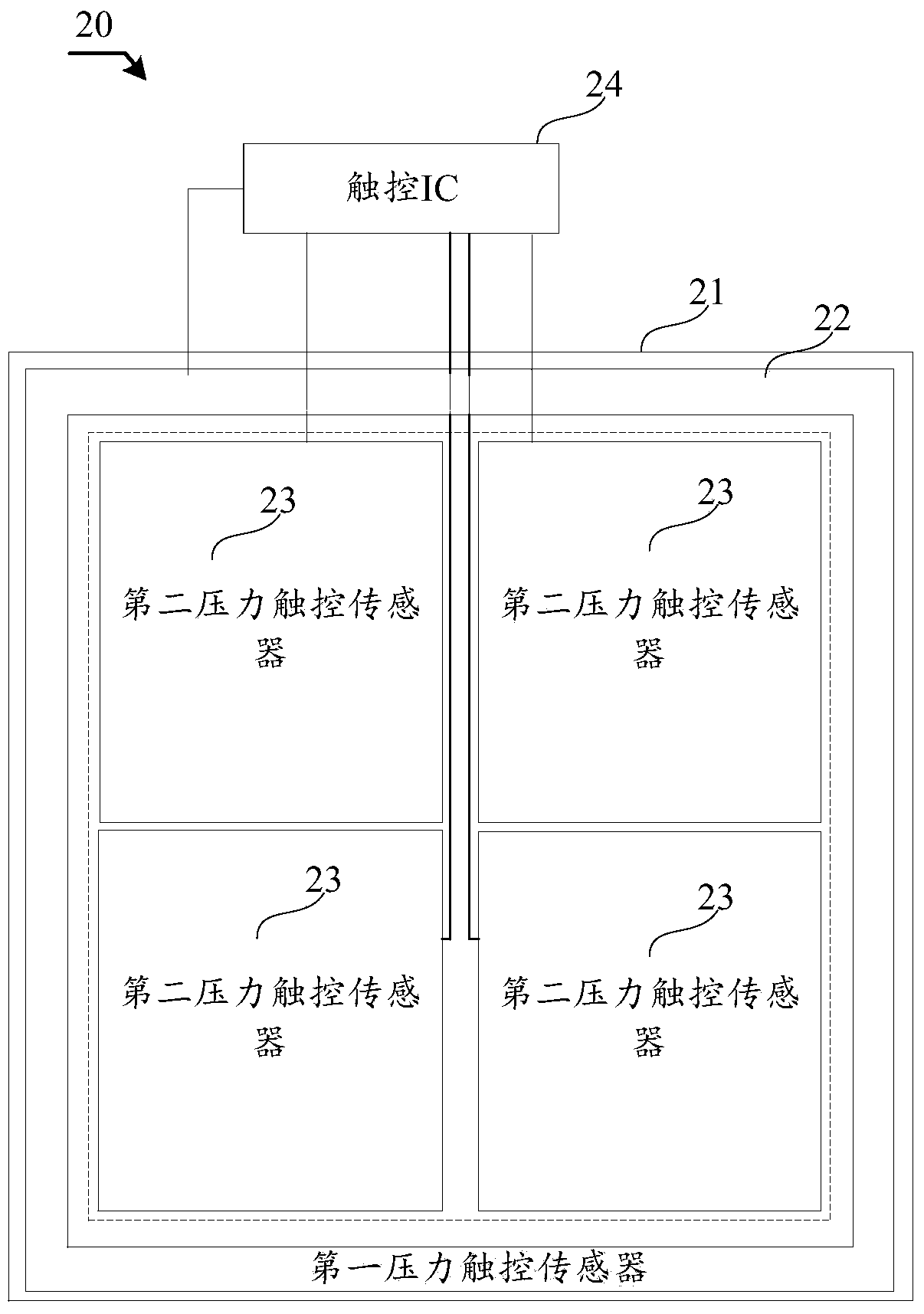

[0046] figure 1 It is a schematic structural diagram of a touch module 10 according to an exemplary embodiment. The touch module 10 may include: a touch screen 11 , a first pressure touch sensor 12 , b second pressure touch sensors 13 and a touch IC 14 , where a is a positive integer and b is a positive integer.

[0047] The projection of each first pressure touch sensor 12 in the plane where the touch screen 11 is lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com