Microcircuit internal atmosphere detection test clamp

A technology of internal atmosphere and test fixture, which is applied in the direction of measuring device, analysis of gas mixture, gas analyzer structure details, etc., can solve the problems of large influence on test results, long time-consuming vacuuming, and inappropriate size, etc., to shorten the test cycle , reduce extra gas, speed up the effect of vacuuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

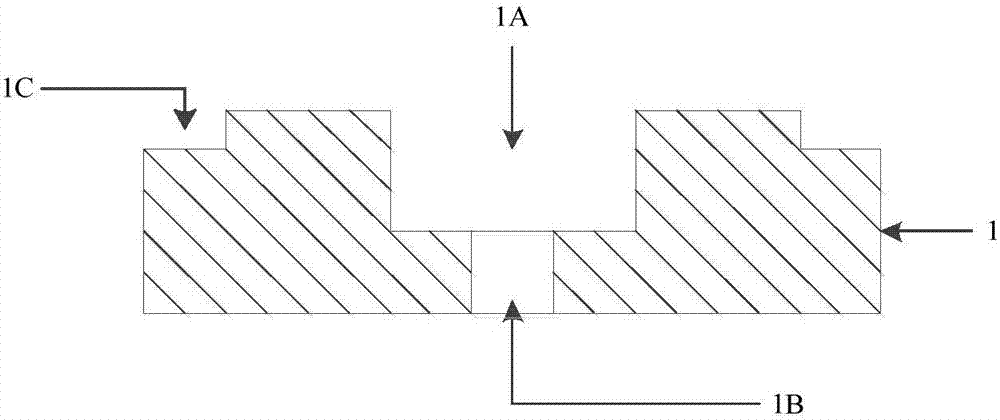

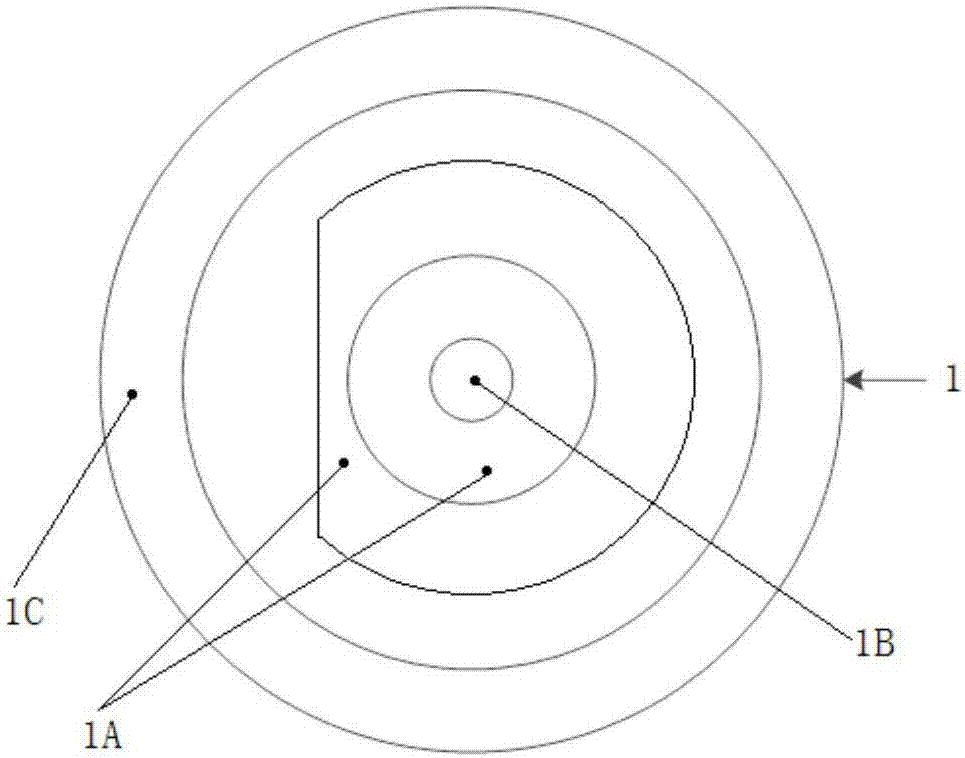

[0028] The embodiment is basically as attached figure 1 , 3 , shown in 4: the present embodiment provides a kind of microcircuit internal atmosphere detection test fixture, and it is made up of mother clip body 1, sub-clip body 2, cover body 3, and the central part of one end of described mother clip body 1 is provided with concave The pressure cavity 1A is used to place the sub-clamp body 2, and the pressure cavity 1A is provided with a through connection channel 1B for accommodating the device to be tested (not shown), and the female clamp body 1 is connected to the pressure cavity 1A The outer edge of the same side of the mouth is provided with a relief part 1C for installing a sealing ring (not shown), and the cover body 3 covers the mouth of the pressure chamber 1A and covers the sealing ring; its female clip body 1 Both the clip body and the sub-clip body 2 adopt an optimal circular structure, of course, in different embodiments, a square or oval structure can also be u...

Embodiment 2

[0035] The difference between this embodiment and Embodiment 1 is that the pressure chamber 1A is two, one large and one small, distributed in a stepped shape, and the cross section of the larger pressure chamber 1A is D-shaped, with a sealing gasket ( not shown). In this way, the sub-fixture 2 also has the same D-shaped cross-section as the larger pressure chamber 1A cross-section, so that the sub-fixture 2 will not rotate in the pressure chamber 1A, and the bottom of the larger pressure chamber 1A is provided with a seal The pad can further seal the connection channel 1B of the female clip body 1, which is beneficial to the internal atmosphere detection test of the device to be tested.

Embodiment 3

[0037] The difference between this embodiment and the first and second embodiments is that the sub-clip body 2 is integrated on the cover body 3 to form an integrated structure; in this way, it is convenient for test operation and fixture arrangement. At the same time, the outer wall of the sub-clamp body 2 is provided with anti-skid lines, forming an interference fit with the pressure chamber 1A, which can further reduce the generation of extra gas inside the clamp.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com