Absorber tray liquid holdup monitoring method for wet flue gas desulfurization system

A wet flue gas desulfurization and liquid holdup technology, which is applied to volume measuring instruments/methods, liquid/fluid solids measurement, measuring devices, etc., can solve the problem of monitoring liquid holdup of wet flue gas desulfurization absorption tower trays that have not yet been found. methods, etc., to achieve the effect of reducing the number of layers, easy to implement, and improving desulfurization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

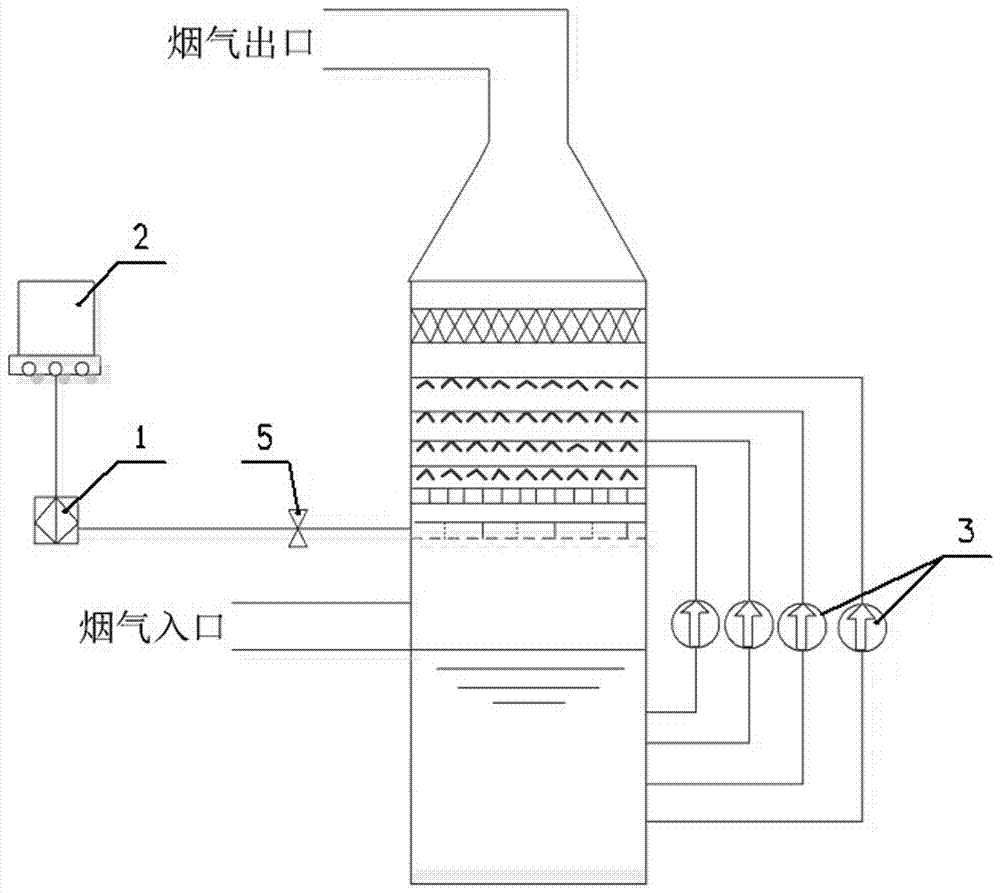

[0024] see figure 1 , the wet flue gas desulfurization system absorption tower tray liquid holdup monitoring method of the present invention monitors the tray liquid holdup by cyclically monitoring the liquid levels at different positions on the tray:

[0025] 1) Arrange pressure detection holes (pressure measurement points) evenly at the bottom of the tray, each pressure detection hole is connected to the pressure sensor 1 through the corresponding pressure measurement pipeline, and the solenoid valve 4 is installed on each pressure measurement pipeline;

[0026] 2) Through the solenoid valve 4, control whether each pressure measuring pipeline is connected with the pressure sensor 1, and selectively or according to a certain rule, test the pressure of the relative position of the corresponding pressure detection hole;

[0027] 3) The output signal of the pressure sensor is connected to the display instrument or the monitoring system 2, and the display instrument or the monito...

Embodiment 2

[0030] see figure 1 , the wet flue gas desulfurization system absorber tray liquid holdup monitoring method of this embodiment differs from Embodiment 1 in that each pressure measuring pipeline is connected to a pressure sensor through a multi-way valve 5, and one pressure sensor is used to realize the whole The monitoring of pallet pressure saves the number of sensors, reduces system complexity and saves investment.

Embodiment 3

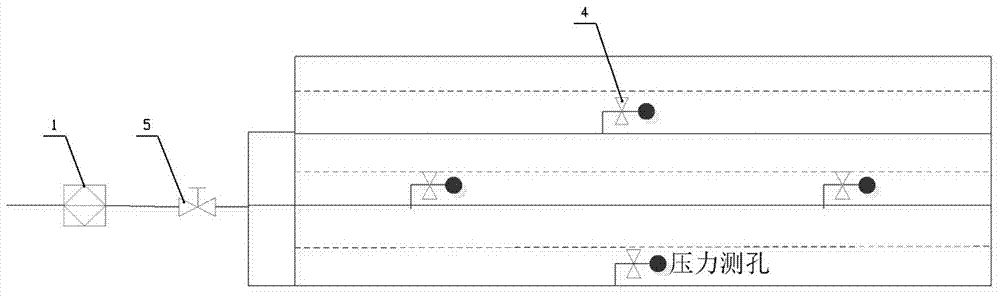

[0032] see figure 1 , figure 2 , the wet flue gas desulfurization system absorption tower tray liquid holdup monitoring method of this embodiment is different from Embodiment 1 in that: the pressure measuring points are set in units and correspond to the trays; each pressure measuring pipe passes through a solenoid valve It is connected to the main pipeline of the pressure measuring point, and then connected to the pressure sensor through a multi-way valve. The upper and lower layers of the main pipeline of the pressure measuring point are arranged in a staggered manner to play the role of uniform gas distribution and partially serve as a tray.

[0033] see figure 2 , the solid line and dotted line are the main pipes of the upper and lower pressure measuring points respectively, and the main pipes of the lower pressure measuring points (shown by the dotted line) are arranged just below the center line of the two upper pressure measuring point main pipes (shown by the solid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com