Building wall verticality testing equipment

A technology for testing equipment and building walls, used in measuring devices, measuring fixed angles, instruments, etc., can solve the problems of uneven wall surface, inability to use, slow detection, etc., to achieve reliable test data, strong detection applicability, The effect of a high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific preferred embodiments.

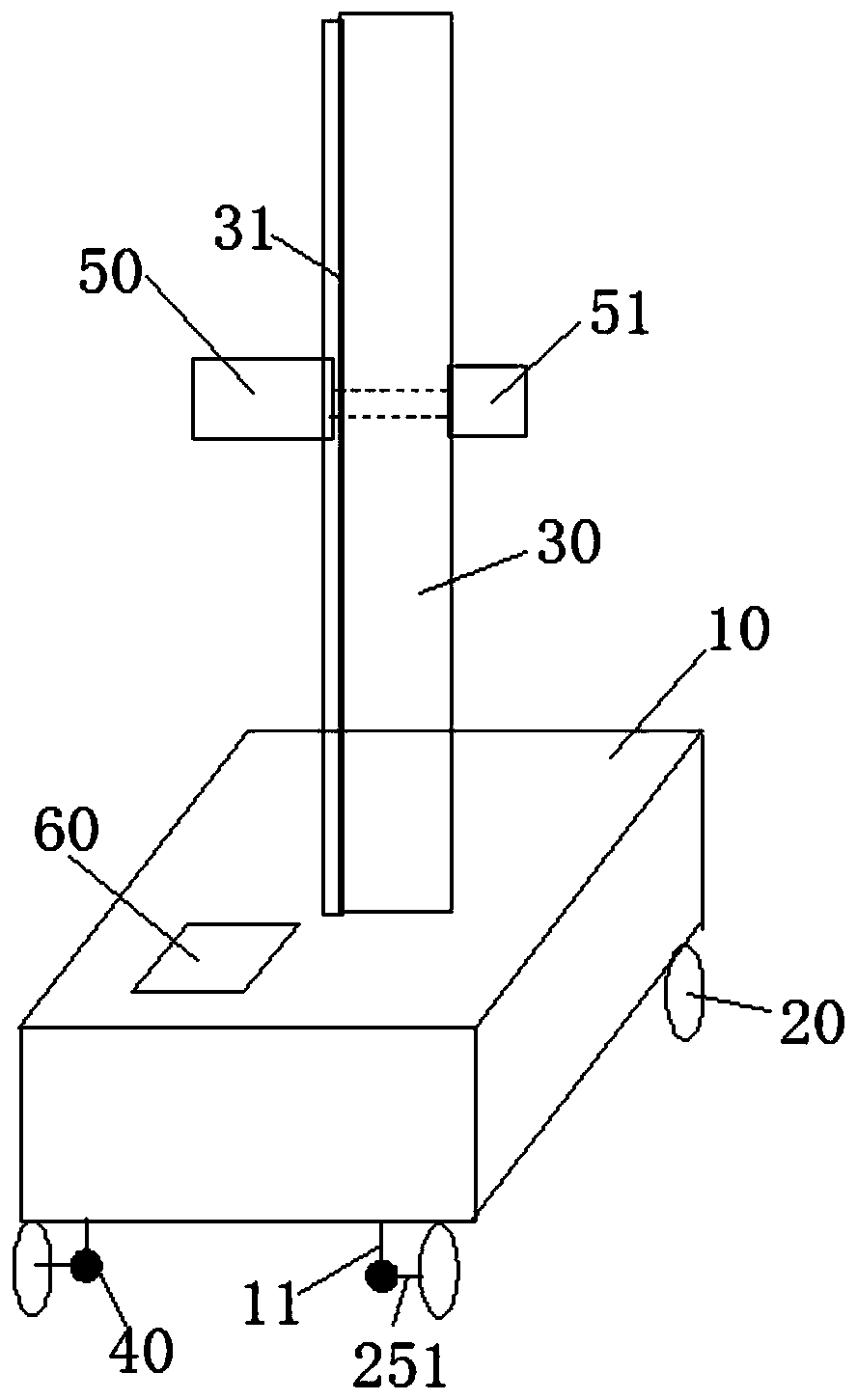

[0041] Such as figure 1 As shown, a building wall verticality detection device includes a horizontal base 10 , driving rollers 20 , a vertical plate 30 , a height sensor 40 , a displacement sensor 50 and a display control panel 60 .

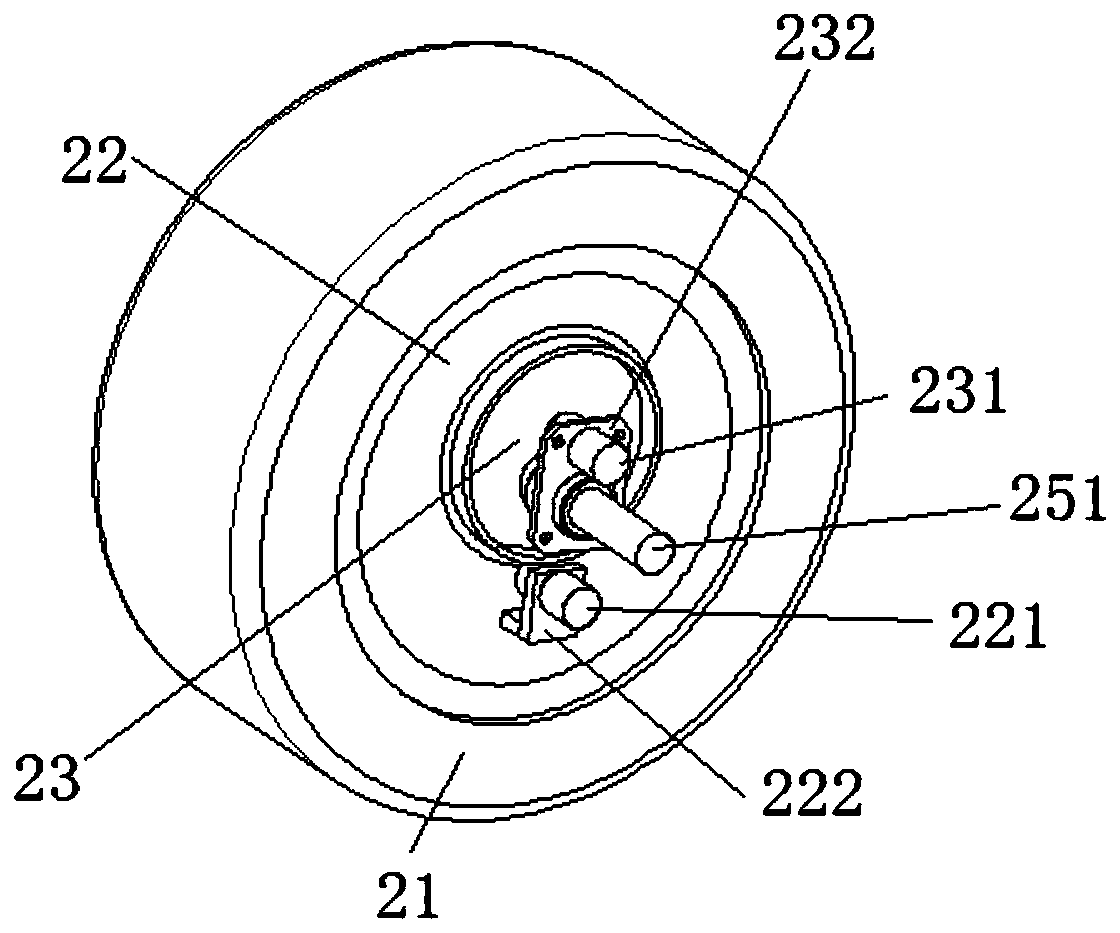

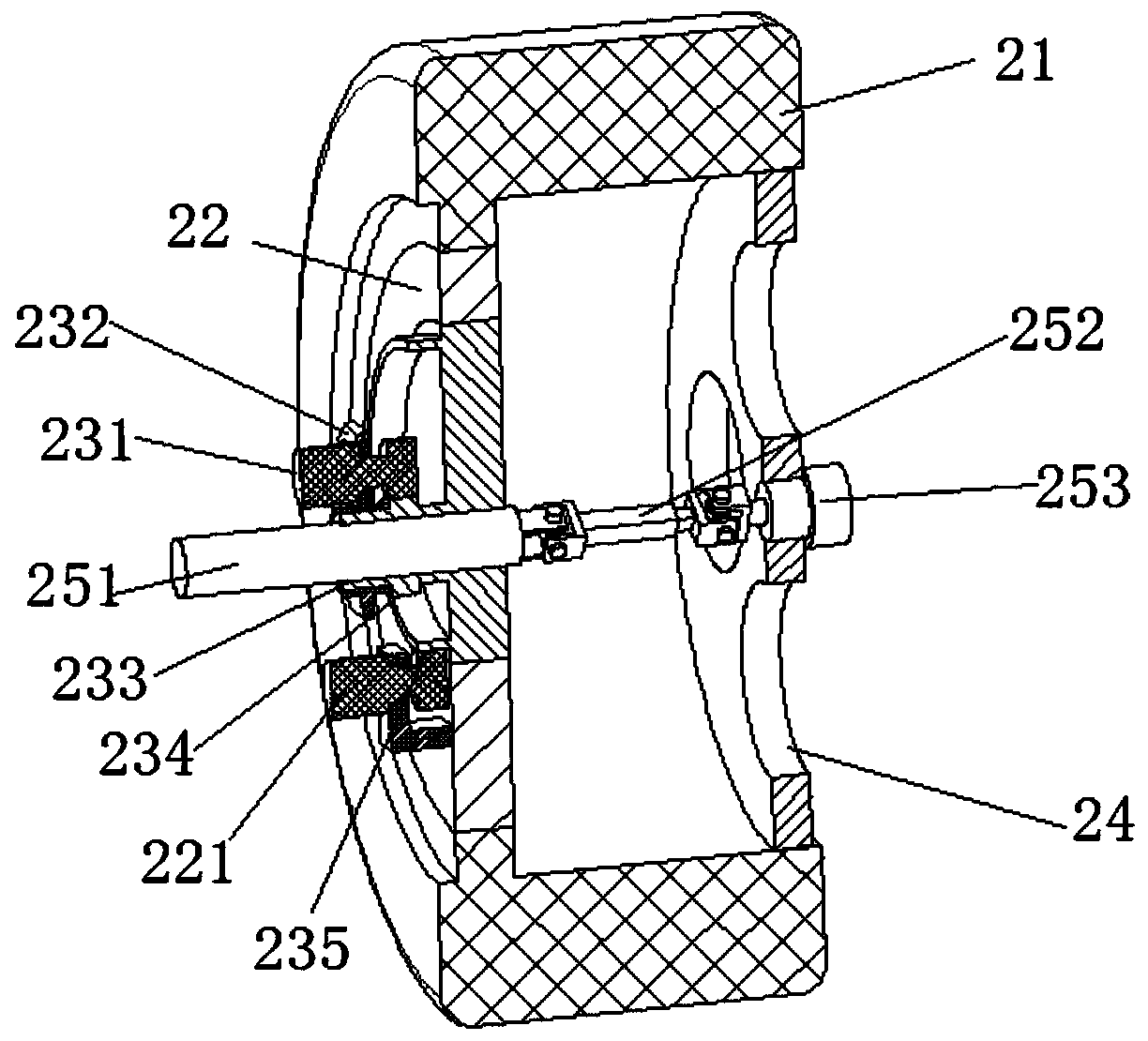

[0042] The bottom of the horizontal base is provided with four driving rollers, and the bottom of the horizontal base is preferably connected to the driving shaft 251 of each driving roller through the cantilever 11 .

[0043] The vertical board is fixedly arranged at the bottom center of the horizontal base, and the vertical board is provided with a vertical slide rail 31 .

[0044] The height of the vertical plate is preferably liftable or foldable, so as to adapt to the detection of the verticality of walls of different heights and to be easy to store. Since lifting or folding are prior ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com