Hand-operated horizontal movement device for air intensifier

A technology of a horizontal moving device and an air intensifier, which is applied in the directions of supporting machines, engine bases, engine frames, etc., can solve the problems of inconvenient installation and inconvenient adjustment of horizontal movement of air intensifiers, and achieves convenient and flexible movement and adjustment. The effect of horizontal flexible movement control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

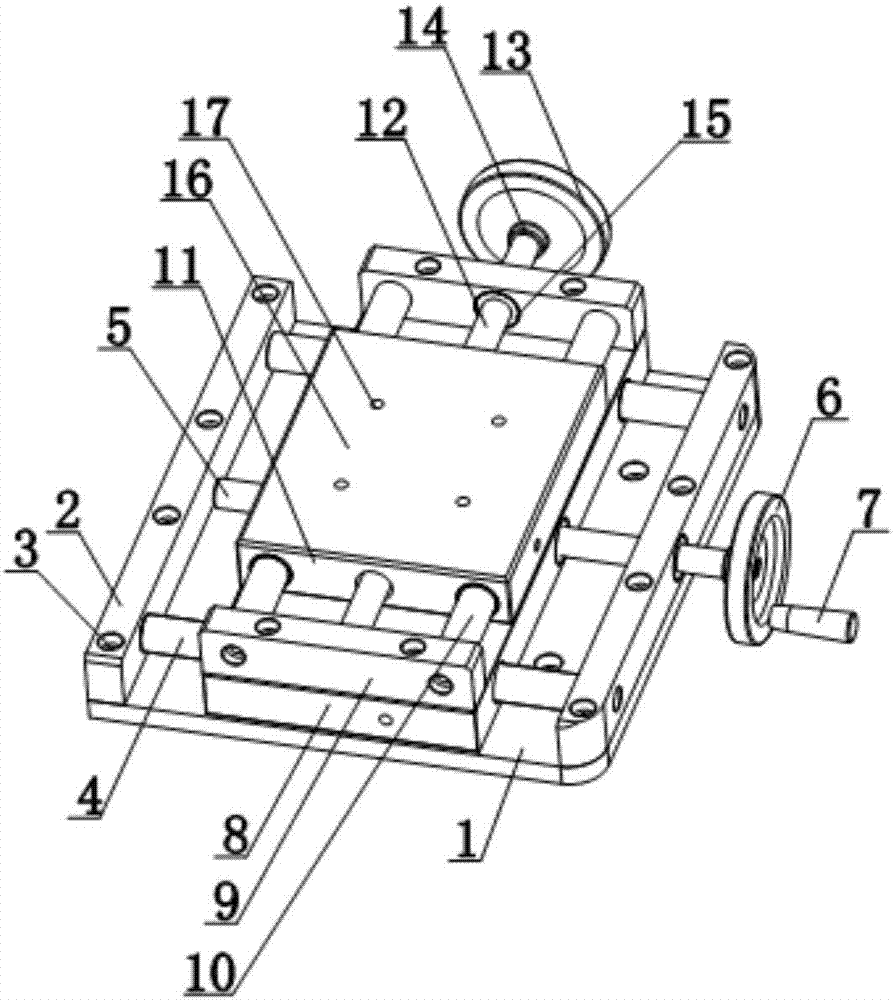

[0014] like figure 1 As shown, a hand-operated horizontal moving device for an air booster includes a bottom plate 1, a first fixed block 2 is provided on both sides of the bottom plate 1, and a first guide shaft 4 is arranged between the two ends of the first fixed block 2 , the middle part of the first fixed block 2 is provided with a first rotating threaded column 5, and the outer end of the first rotating threaded column 5 is provided with a first rotating wheel 6; the first guide shaft 4 and the first rotating threaded column 5 are sleeved with Moving plate 8, the both sides of moving plate 8 are all provided with the second fixed block 9, be provided with the second guide shaft 10 between the two ends of the second fixed block 9, be provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com