Hoop type feeder clamp facilitating pipe diameter adjusting

A technology of feeder card and tube diameter, which is applied in the field of optical fiber communication, can solve the problems of fixed size of feeder card and small application range, etc., and achieve good fixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

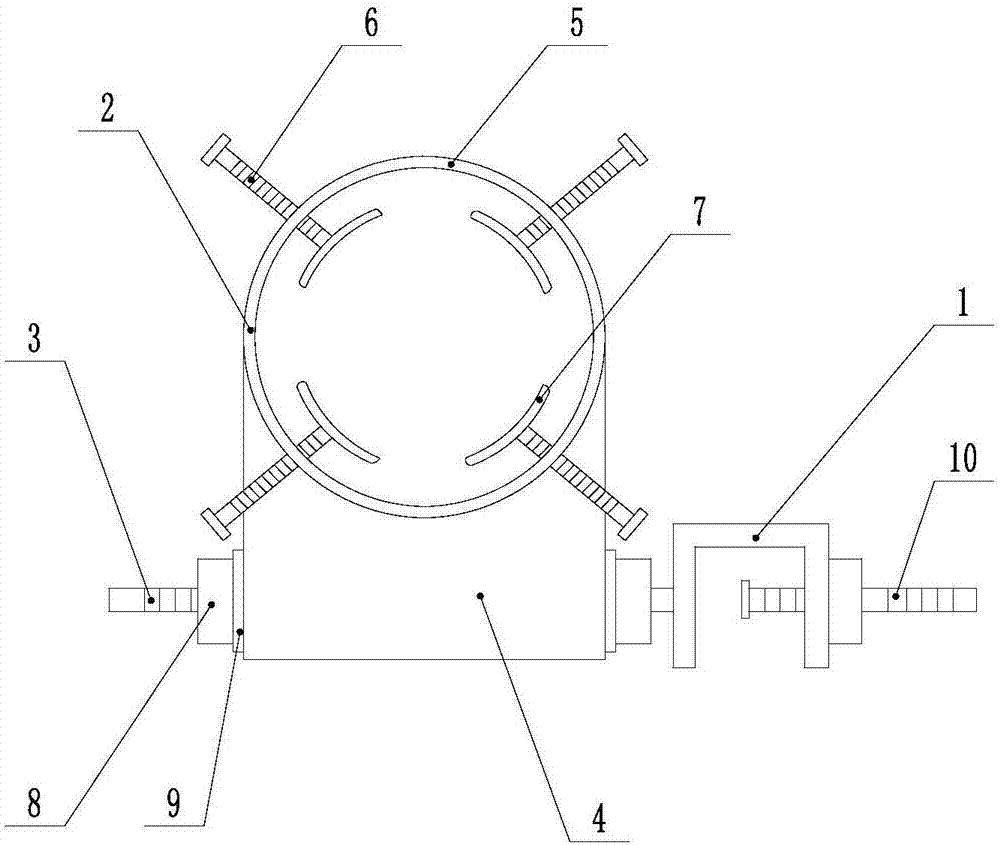

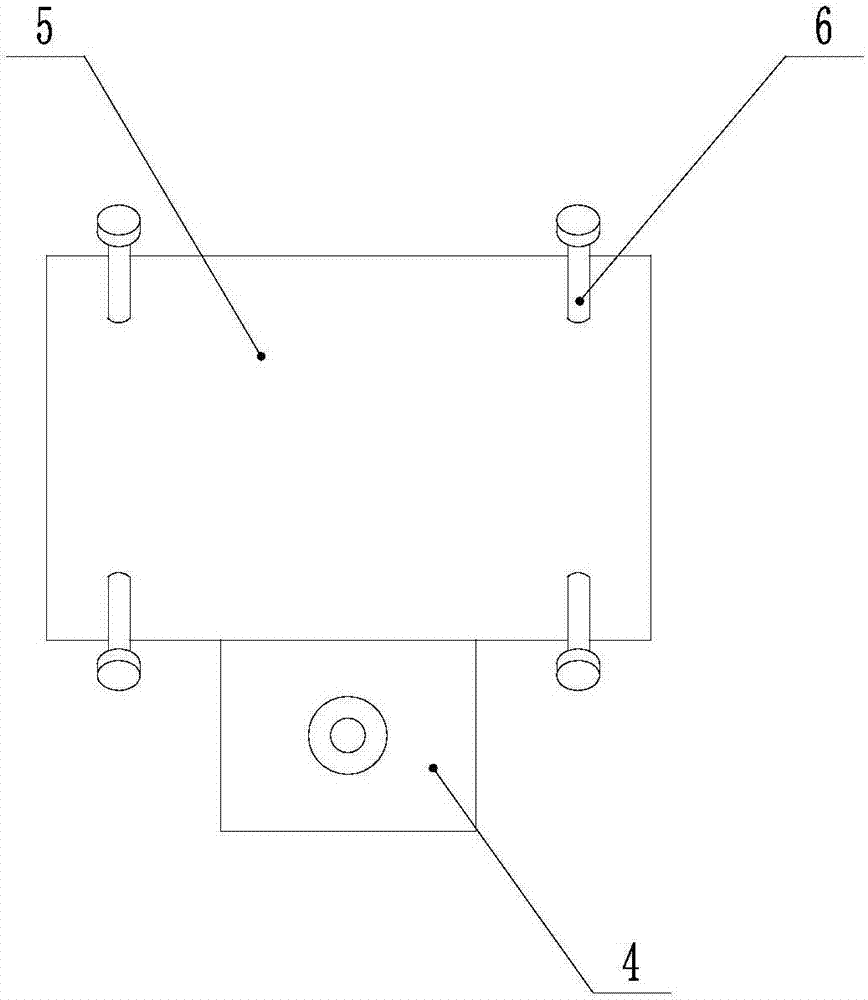

[0027] like figure 1 , figure 2 As shown, the hoop-type feeder card, which is convenient for adjusting the pipe diameter, includes a C-type fixing frame 1 and an optical fiber sheath 2, and the C-type fixing frame 1 and the optical fiber sheath 2 are connected by a screw 3; The installation part 5, the screw 3 passes through the connection part 4, and can be fixed on the connection part 4, the installation part 5 is a cylindrical structure provided with a through hole, and a telescopic rod 6 is arranged through the pipe wall, and the telescopic rod 6 can be The end of the telescopic rod 6 located in the through hole of the installation part 5 is provided with an arc-shaped adjustment plate 7, and the C-type fixing frame 1 has three installation surfaces, and the installation surface has a fixing function in the horizontal and vertical directions. The screw 10 can fix the C-shaped fixing frame on the wall or other plane. Compared with the existing feeder card, the telescopic ...

Embodiment 2

[0030] This embodiment further describes the present invention on the basis of Embodiment 1.

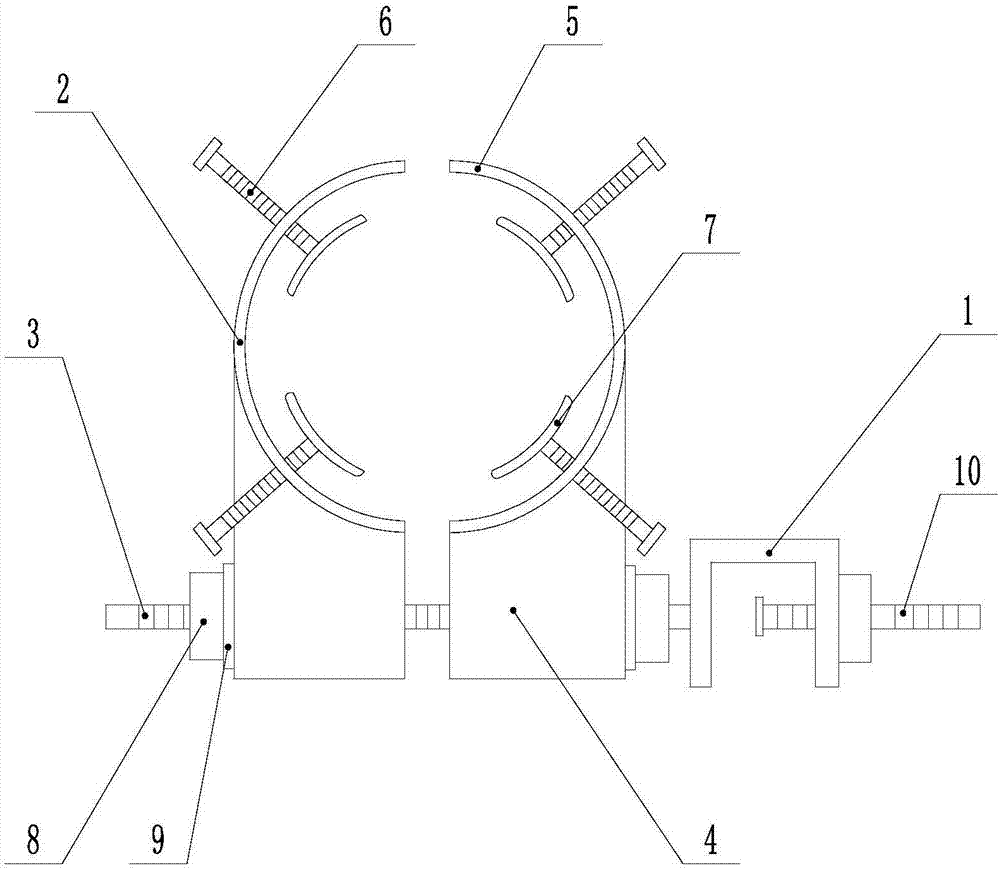

[0031] like image 3 As shown, the hoop-type feeder card is convenient for adjusting the pipe diameter. The connecting part 4 and the mounting part 5 are divided into two parts. The mounting part 5 is divided into two symmetrical semi-cylinders, and the two parts of the mounting part 5 are respectively connected to the connecting part. On the two parts of 4, the two parts of the connecting part 4 are connected by the screw 3, and both parts of the connecting part 4 can move along the axis of the screw 3. By adjusting the distance between the two parts of the connecting part 4, the installation can be adjusted. The distance between the two parts of section 5 makes it suitable for optical fibers of different specifications and has a wider application range.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com