Any pressure relief curve pressure control method of hydraulic pressure device

A control method and curve pressure technology, applied in fluid pressure actuation devices, fluid pressure actuation system testing, fluid pressure actuation system components, etc., to meet process requirements and improve the effect of pressure relief pressure curve control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described below in conjunction with the accompanying drawings.

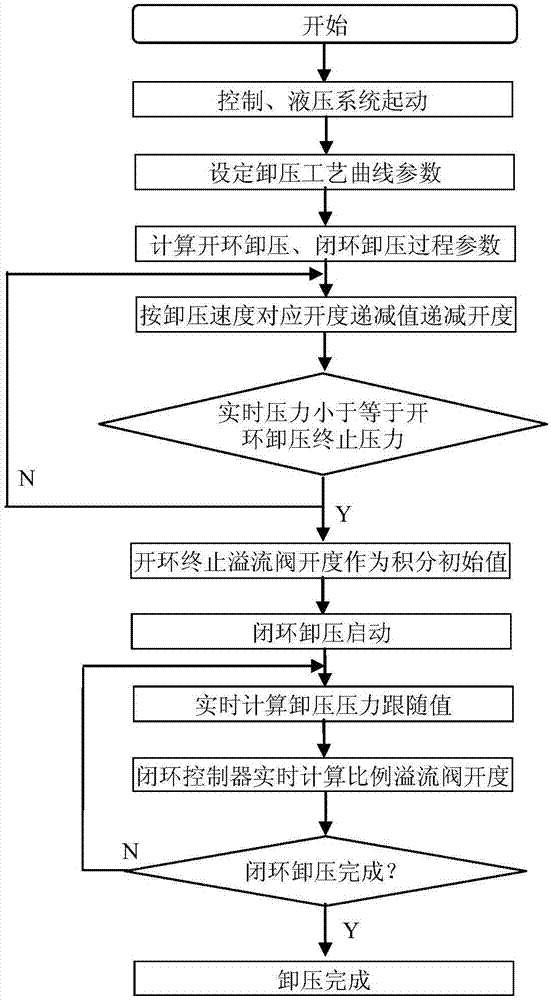

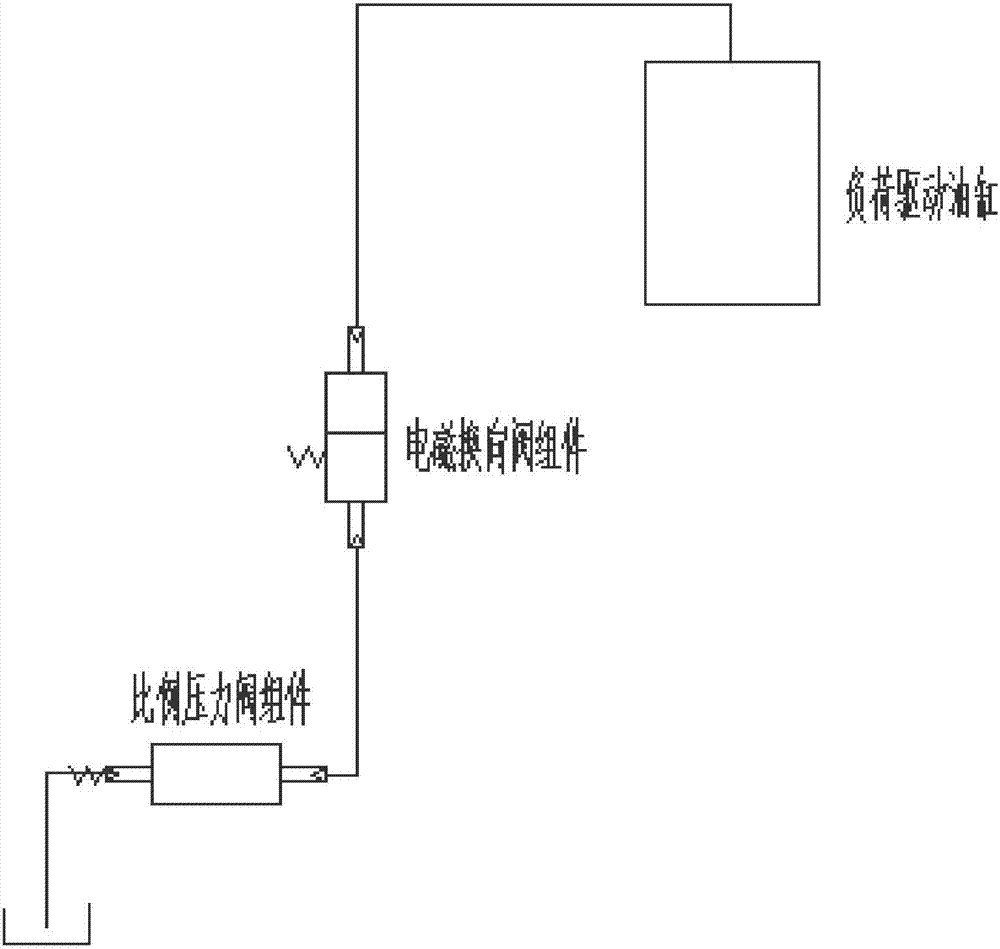

[0052] as attached figure 1 , 2 As shown, a pressure control method for an arbitrary pressure relief curve of a hydraulic pressure device, including: a calculation method for the opening degree of the proportional relief valve at the beginning of pressure relief, a calculation method for the opening degree of the proportional relief valve for open-loop pressure relief, and a calculation method for closed-loop pressure relief control Method, by running the above calculation method on the processor of the control system, the precise control of the pressure relief process is realized. Specifically:

[0053] 1) Calculation method of proportional relief valve opening at the beginning of pressure relief, which requires:

[0054] a) design experiments, and carry out mathematical model modeling on the hydraulic pressure loading system;

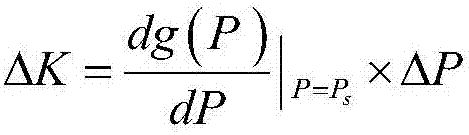

[0055] b) The data acquisition platfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com