A 110kv overhead line front and rear cable type double circuit steel pole type terminal tower

A technology for cable terminals and overhead lines, which is applied in the field of cable-type double-circuit steel pipe pole-type terminal towers before and after 110kV overhead lines. Operation, reduce floor space and reduce investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to better understand the present invention, the implementation manner of the present invention will be explained in detail below in conjunction with the accompanying drawings.

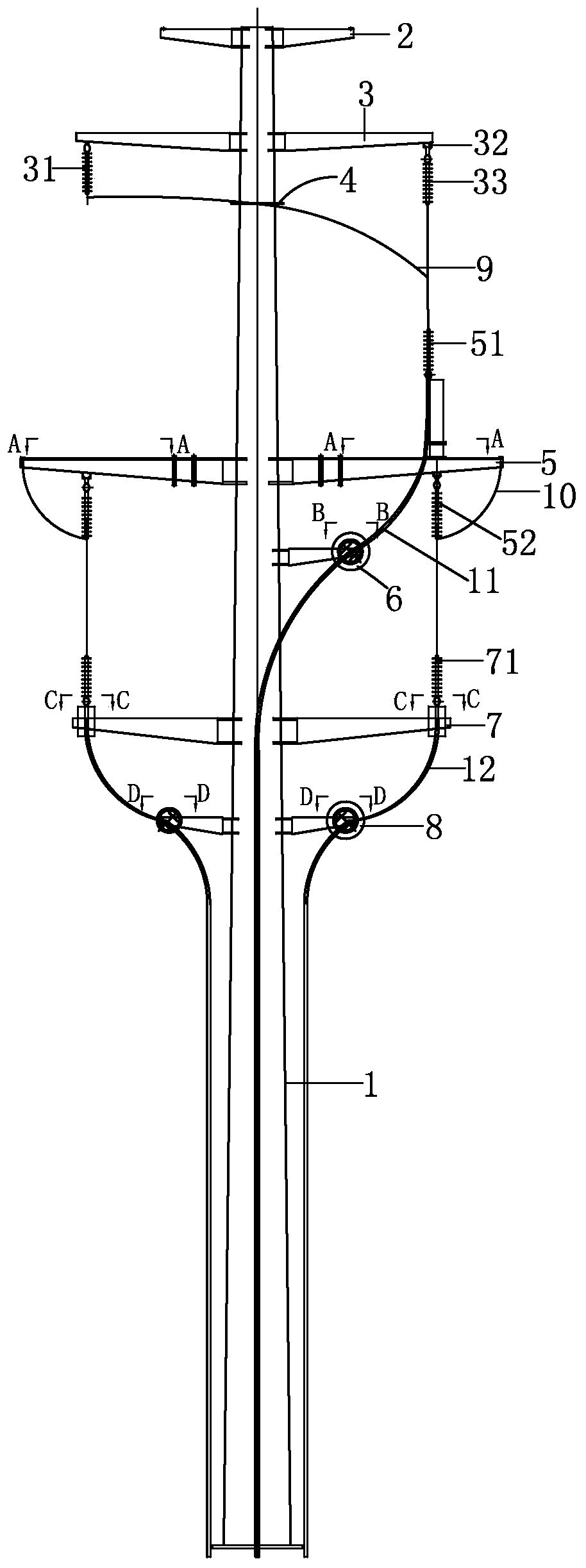

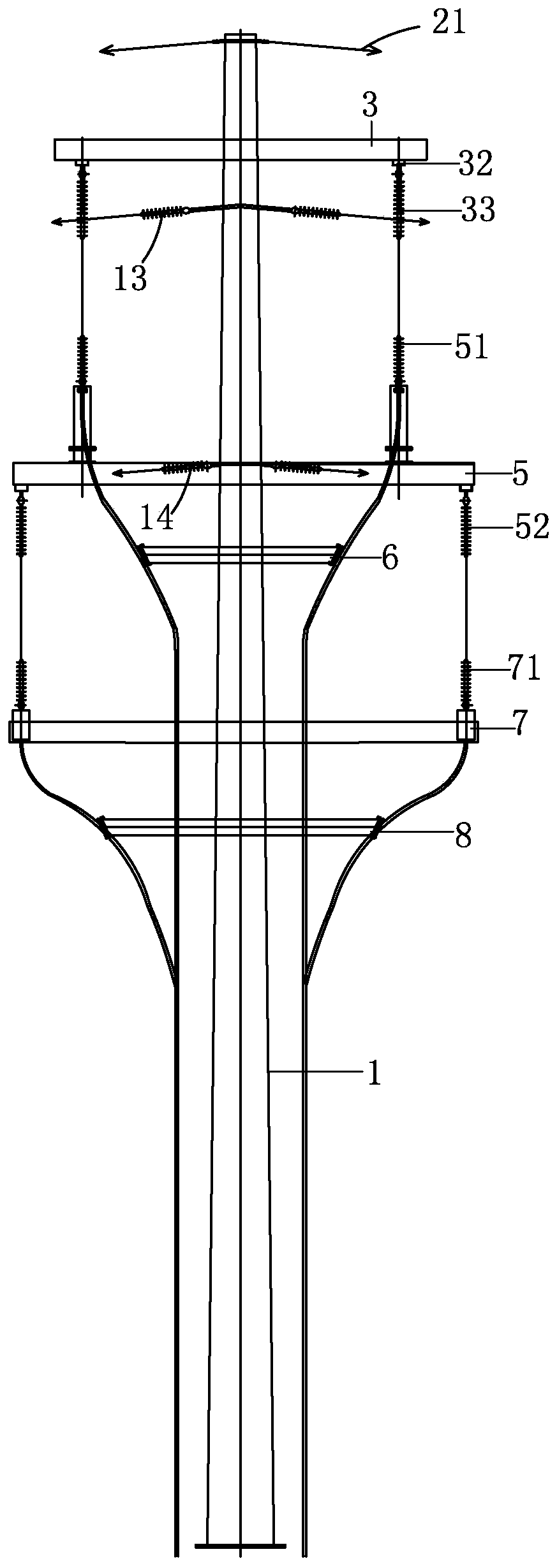

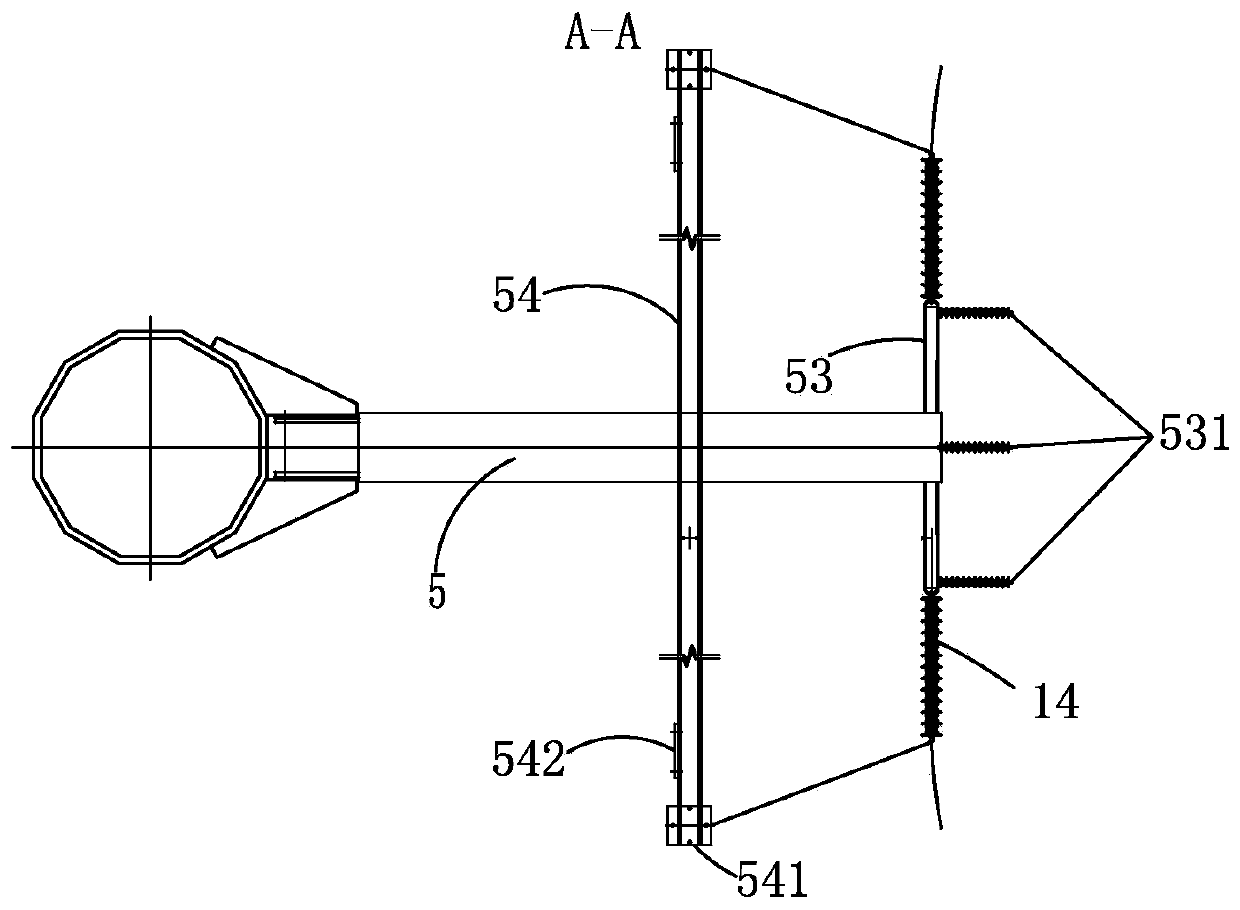

[0025] Such as Figure 1 to Figure 6 As shown, a 110kV overhead line front and rear cable-type double-circuit steel pole terminal tower includes a tower body 1, a front overhead circuit, a rear overhead circuit, a lightning arrester, cables, and cable terminals. The tower body is sequentially provided with Lightning conductor cross-arm 2, middle-phase wire jumper series cross-arm 3, middle-phase wire cross-arm 4, side-phase wire cross-arm 5, middle-phase cable fixed cross-arm 6, side-phase cable terminal fixed cross-arm 7, side-phase cable Fixed cross-arm 8; the front overhead circuit and the rear overhead circuit are two loops of independent operation; the front overhead circuit and the rear overhead circuit all include two lightning conductors 21, a middle phase conductor 9, and a sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com