Fabricated point-anchor retaining wall

A prefabricated, retaining wall technology, applied in water conservancy projects, artificial islands, excavation, etc., can solve the problems of long construction period and high cost, and achieve the effects of component quality assurance, accurate size and fast implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

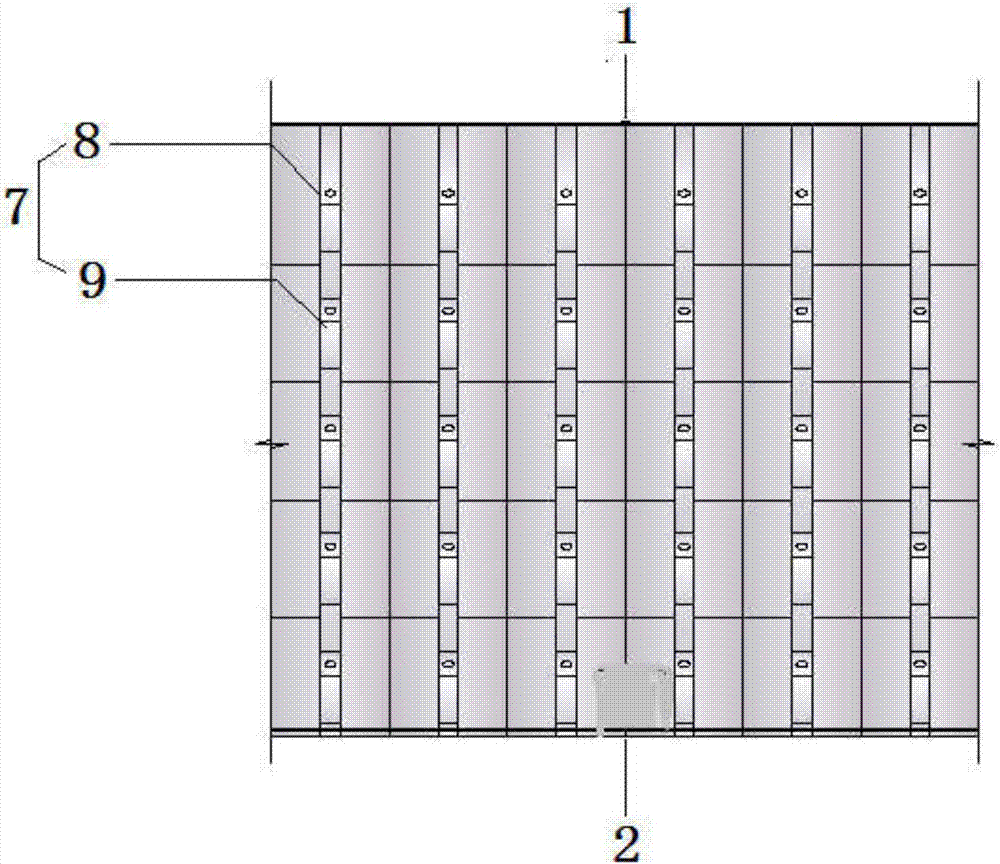

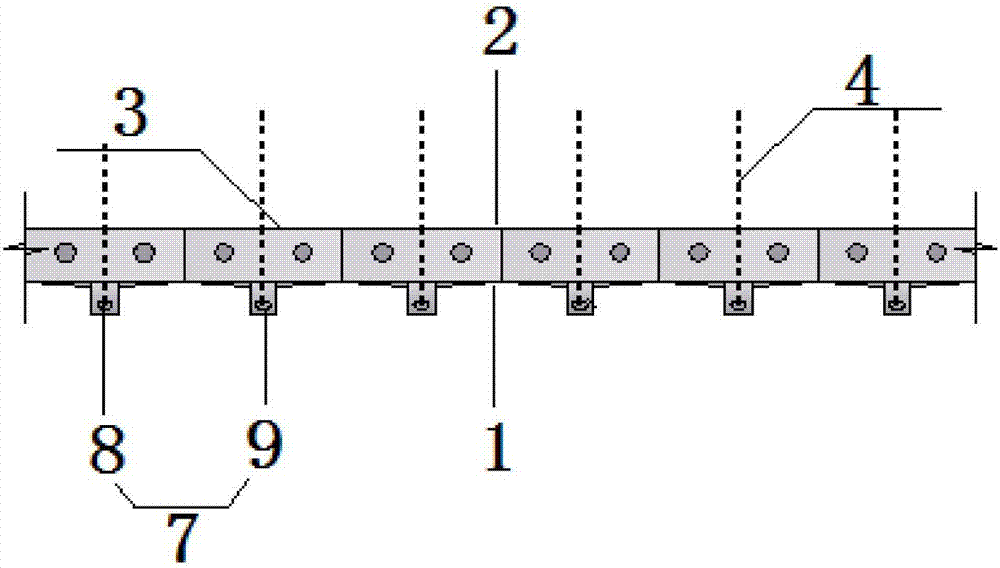

[0019] Example: see Figure 1-5 , a new type of prefabricated point anchor retaining wall of the present invention, comprising a slope top 1, a rotary grouting pile 3, a prestressed anchor cable 4 and a prefabricated anchor block assembly 7, and a rotary grouting pile is installed between the slope top 1 and the slope bottom 2 Pile 3, the prestressed anchor cable 4 passes through the rotary grouting pile 3 and the sliding fracture surface 5 in turn, the right end of the prestressed anchor cable 4 is fixedly connected with the rotary grouted anchor 6, and the left end of the prestressed anchor cable 4 It is fixed on the left side of the rotary grouted pile 3 by the prefabricated anchor block assembly 7, the prefabricated anchor block assembly 7 includes a top prefabricated anchor block 8 and a plurality of top prefabricated anchor blocks 9, and the bottom of the top prefabricated anchor block 8 and the standard The upper and lower parts of the prefabricated anchor block 9 are p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com