Water-based wool-feel bottoming material and preparation method thereof

A technology of cashmere feeling and base material, which is applied in the field of surface treatment agents for synthetic leather, can solve the problems that surface treatment agents cannot meet the demand, and achieve the effect of unique hand feeling, good temperature resistance and increased cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

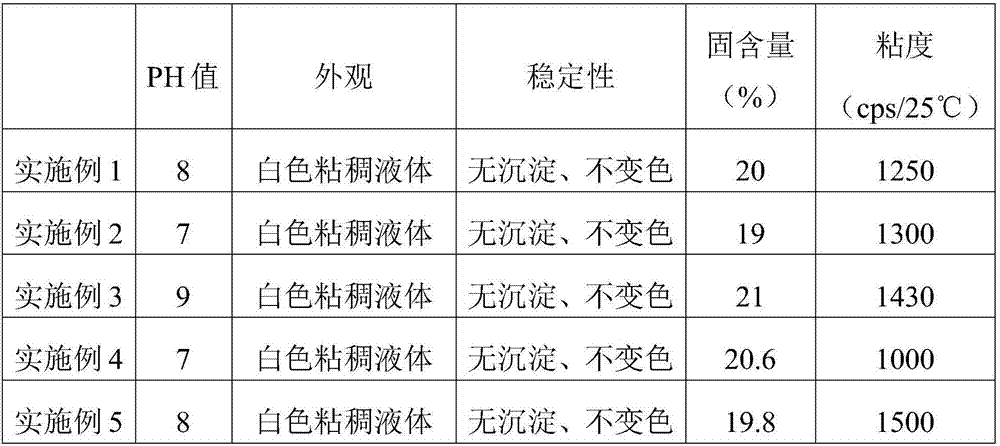

Examples

Embodiment 1

[0020] The water-based velvet primer is composed of the following components: 41kg water-based resin, 42kg deionized water, 4kg butyl ether, 4kg isopropanol, 6kg silica matting powder, 2.3kg thickener, 0.4kg dispersant , Wetting agent 0.3kg.

[0021] The preparation method of the water-based velvet feeling primer of the embodiment of the present invention 1 comprises the following steps:

[0022] 1) Weigh each component in proportion, mix 20.5kg water-based resin with 42kg deionized water, 4kg butyl ether, 4kg isopropanol, 6kg silica matting powder, 0.4kg dispersant and 1.15kg thickener Stir well;

[0023] 2) Add 0.3kg of wetting agent to the mixture obtained in step 1), and stir evenly;

[0024] 3) Slowly add the remaining 1.15kg of thickener, and check the viscosity value of the mixture. The obtained detection value is 1250cps / 25°C, and the mixture is qualified;

[0025] 4) Add the remaining 20.5 kg of water-based resin to the qualified mixture obtained in step 3), and st...

Embodiment 2

[0027] The water-based velvet primer is composed of the following components: 40kg of water-based resin, 38kg of deionized water, 4.2kg of butyl ether, 4kg of isopropanol, 5kg of silica matting powder, 2kg of thickener, and 0.3kg of dispersant , Wetting agent 0.3kg.

[0028] The preparation method of the water-based velvet feeling primer of the embodiment of the present invention 2 comprises the following steps:

[0029] 1) Weigh each component material in proportion, mix and stir 20kg water-based resin, 38kg deionized water, 4.2kg butyl ether, 4kg isopropanol, 5kg silica matting powder, 0.3kg dispersant and 1kg thickener Uniform;

[0030] 2) Add 0.3kg of wetting agent to the mixture obtained in step 1), and stir evenly;

[0031] 3) Slowly add the remaining 1kg of thickener, and check the viscosity value of the mixture. The obtained detection value is 1000cps / 25°C, and the mixture is qualified;

[0032] 4) Add the remaining 20kg of water-based resin to the qualified mixture...

Embodiment 3

[0034] The water-based velvet primer is composed of the following components: 45kg water-based resin, 43kg deionized water, 5kg butyl ether, 5kg isopropanol, 8kg silica matting powder, 5kg thickener, 0.5kg dispersant, Wetting agent 0.5kg.

[0035] The preparation method of the water-based velvet feeling primer of the embodiment of the present invention 3 comprises the following steps:

[0036] 1) Weigh each component material in proportion, mix 22.5kg water-based resin with 43kg deionized water, 5kg butyl ether, 5kg isopropanol, 8kg silica matting powder, 0.5kg dispersant and 2.5kg thickener Stir well;

[0037] 2) Add 0.5 kg of wetting agent to the mixture obtained in step 1), and stir evenly;

[0038] 3) Slowly add the remaining 2.5kg thickener, and check the viscosity value of the mixture. The obtained detection value is 1430cps / 25°C, and the mixture is qualified;

[0039] 4) Add the remaining 22.5 kg of water-based resin to the qualified mixture obtained in step 3), and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com