A method for jointly extracting igy, phosvitin, lecithin, egg oil and defatted egg yolk powder from egg yolk

A high yolk protein and combined extraction technology, applied in the field of egg deep processing, can solve the problems of complex composition of egg yolk, difficulty in making the best use of everything, and few researches on comprehensive utilization of egg yolk, etc. The effect of high oil lift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

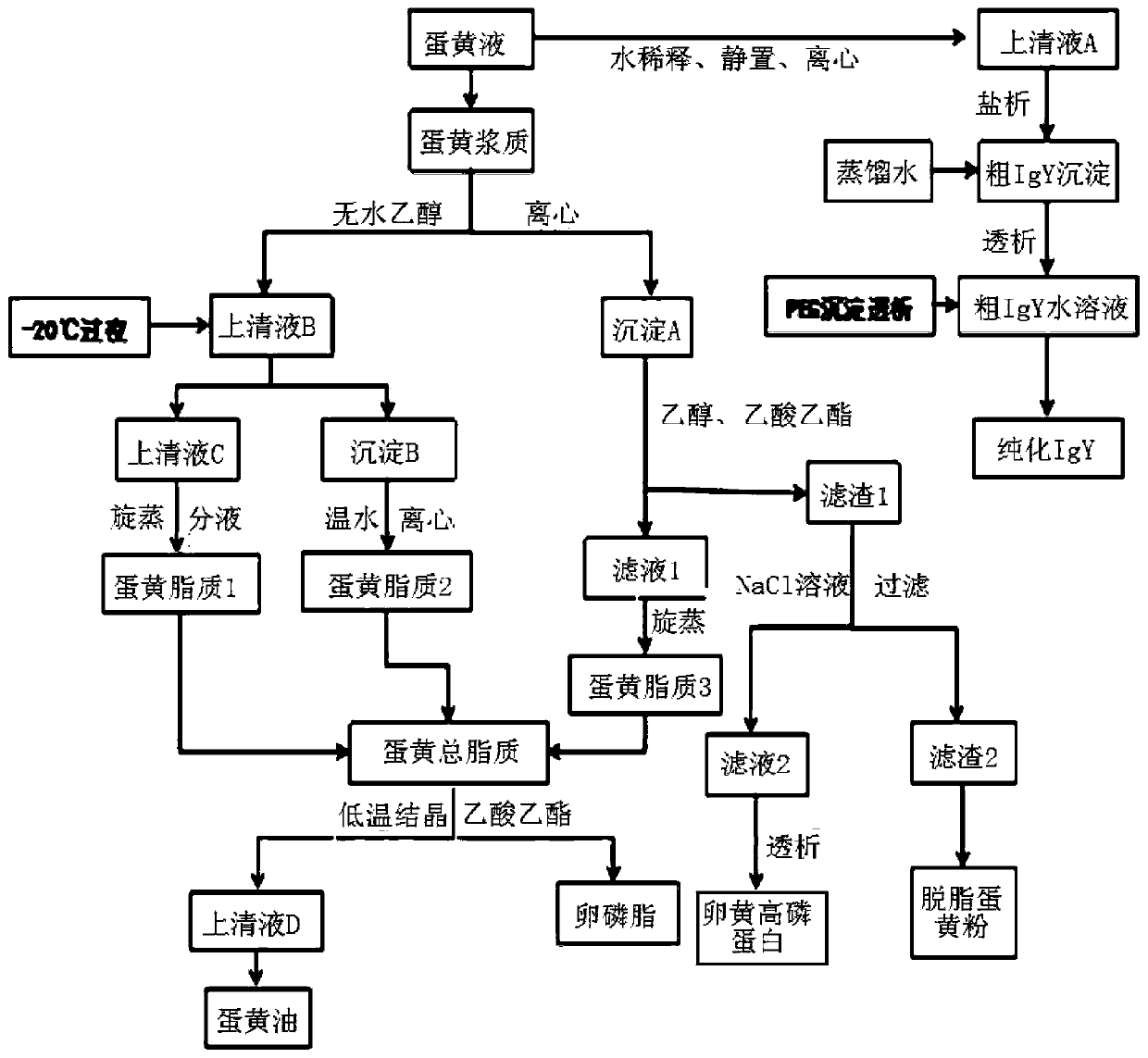

Image

Examples

Embodiment 1

[0022] (1) Take 500ml egg yolk stock solution, add 9 times volume of distilled water to dilute, adjust pH=5.5, stir well and let stand overnight in a refrigerator at 4℃, take it out and centrifuge at 10000rpm for 15min to obtain supernatant A and egg yolk slurry; Add ammonium sulfate and sodium chloride to supernatant A to precipitate IgY, so that the final weight concentrations of the two reach 28% and 0.5%, respectively. Then, the precipitate obtained by centrifugation is completely dissolved in distilled water, and the crude IgY aqueous solution is obtained after dialysis to remove salt. Then add PEG6000 to the crude IgY aqueous solution and adjust the pH=5.0. The final weight concentration of PEG6000 is 8%, put it in the refrigerator for 1h and centrifuge to obtain the purified IgY precipitate. Finally, the purified IgY precipitate is re-dissolved in distilled water and dialyzed Remove PEG6000 to obtain purified IgY aqueous solution, which can be lyophilized to obtain IgY fi...

Embodiment 2

[0029] (1) Take 500ml of egg yolk stock solution, add 3 times volume of distilled water to dilute, adjust pH=4, stir well and let stand overnight in a refrigerator at 4℃, rotate at 10000rpm, centrifuge for 15min, obtain supernatant A and egg yolk slurry; then supernatant Solution A was added with ammonium sulfate and sodium chloride to precipitate IgY, so that the final concentration reached 20% and 1%, respectively, and then the precipitate obtained by centrifugation was completely dissolved in distilled water, and the crude IgY aqueous solution was obtained after dialysis and desalination, and then added to the crude IgY aqueous solution Add PEG6000 and adjust the pH=7.0, the final concentration of PEG6000 is 4%, put it in the refrigerator for 1h and centrifuge to obtain the purified IgY precipitate. Finally, the purified IgY precipitate is dissolved in distilled water again, and the PEG6000 is removed by dialysis to obtain purified IgY. Aqueous solution, IgY finished product ...

Embodiment 3

[0036] (1) Take 500ml of egg yolk stock solution, add 12 times the volume of distilled water to dilute, adjust pH=7.0, stir well and let stand overnight at 4℃, rotate speed 10000rpm, centrifuge for 15min to obtain supernatant A and egg yolk slurry; then add supernatant A IgY was precipitated with ammonium sulfate and sodium chloride to make the concentration reach 35% and 0.1% respectively, and then the precipitate obtained by centrifugation was completely dissolved in distilled water, and the crude IgY aqueous solution was obtained after dialysis to remove the salt, and then PEG6000 was added to the crude IgY aqueous solution and Adjust pH=3.0, PEG concentration is 10%, put in the refrigerator for 1h and centrifuge to obtain purified IgY precipitate. Finally, the purified IgY precipitate is dissolved in distilled water again, and dialyzed out PEG6000 to obtain purified IgY aqueous solution, which is freeze-dried IgY finished products can be obtained;

[0037] (2) Add 400ml of ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com