Production line for tenofovir

A production line, a pair of technologies, applied in the direction of sustainable manufacturing/processing, chemical industry, climate sustainability, etc., can solve the problems of hindering precipitation reaction, low product purity, low distillation efficiency, etc., to reduce calorific value and product purity High efficiency and high distillation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

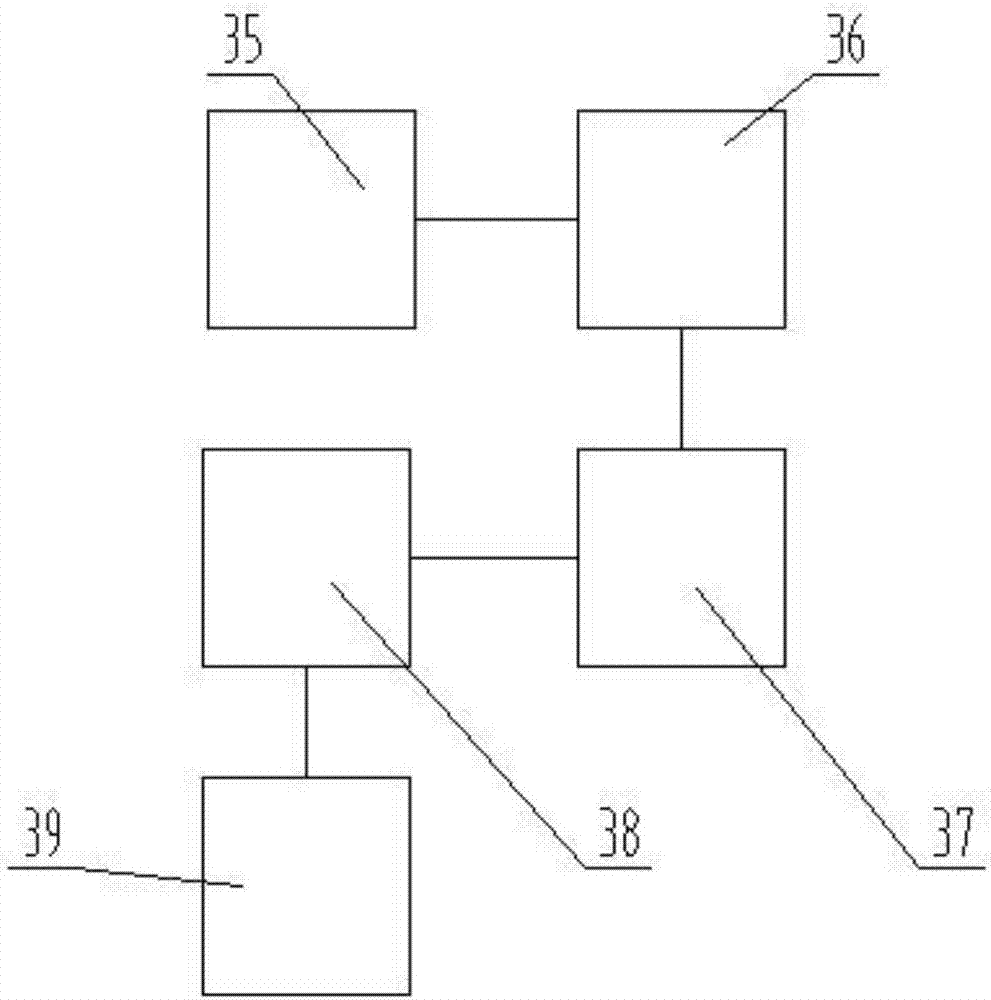

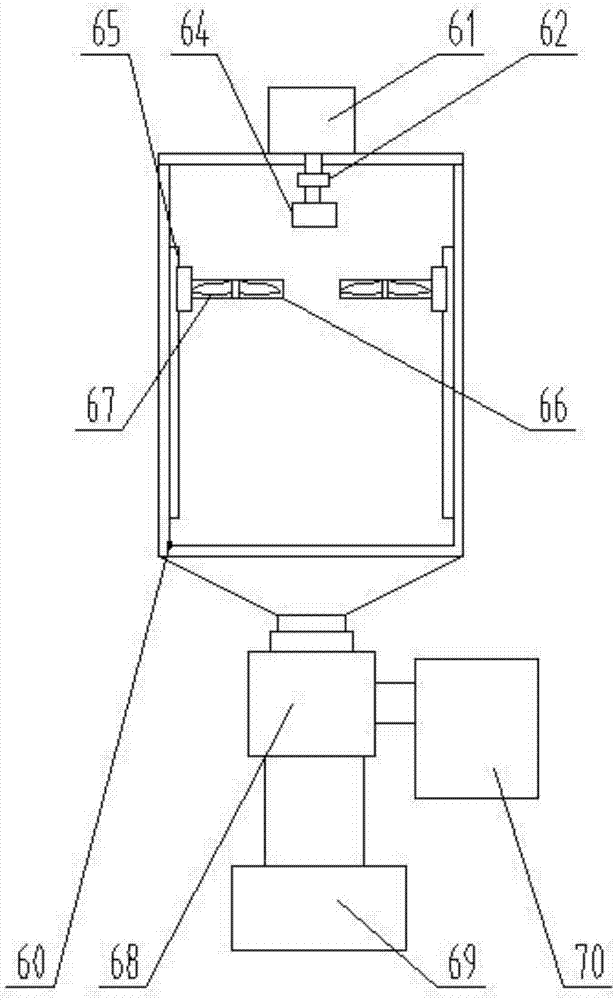

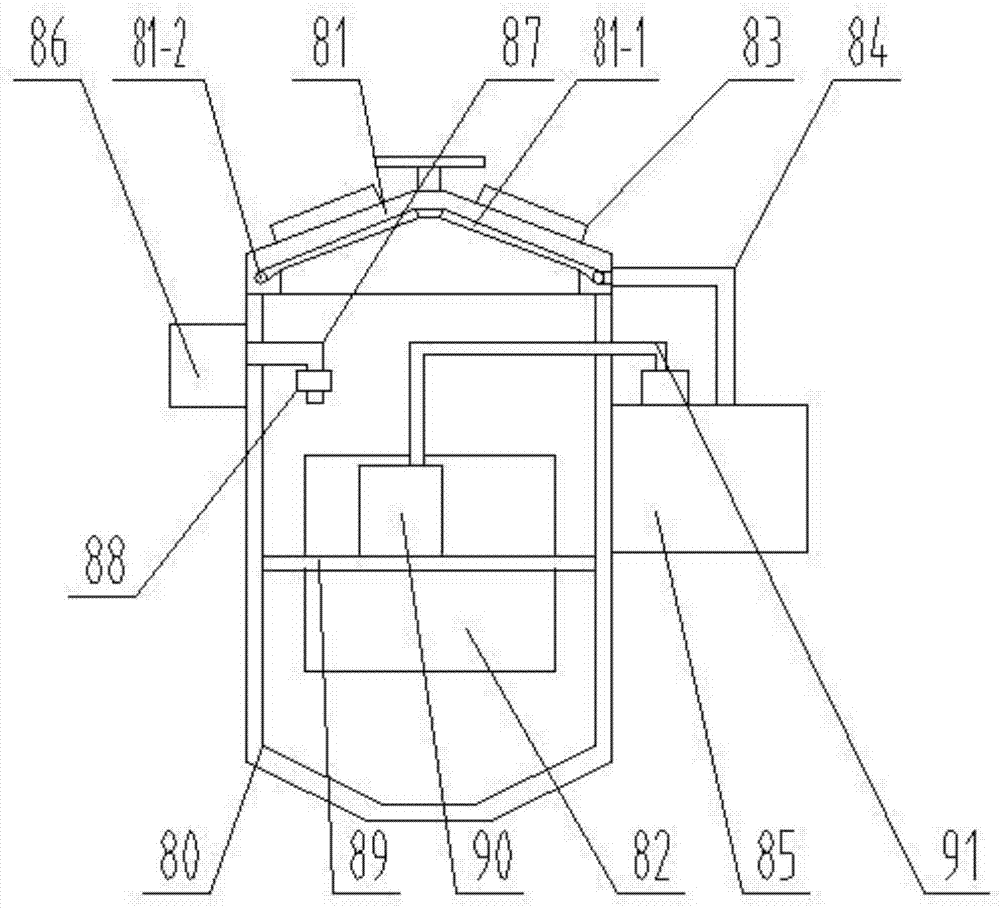

[0020]As shown in the accompanying drawings, the present invention includes a primary reactor 35, a low-temperature reactor 36, a distillation reactor 37, a secondary reactor 38 and a reclaiming precipitation tank 39, and the primary reactor 35 includes a reactor body 10 and at least two uniform reactors. The material plate 11, the two ends of the leveling plate 11 are respectively provided with rotating shafts, the reaction kettle is provided with the mounting bracket 12 of the leveling plate 11, the rotating shaft at one end of the leveling plate 11 is provided with a gear 13, and the gears 13 of a plurality of leveling plates 11 It also has a ring gear driver 15, which is provided with a variable speed gear set and a rocker, and the ring gear driver 15 is installed on the top of the reactor body 10, and drives the ring gear 14 to rotate; The discharge pipe of the reactor body 10 is provided with a filter screen 16; the low-temperature reactor 36 includes a low-temperature re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com