Alcoholysis method of polylactic acid catalyzed by cao/mcf mesoporous basic molecular sieve

A molecular sieve catalyzed alcohol and polylactic acid technology, which is applied in the direction of molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of difficult catalyst separation, cumbersome synthesis steps, harsh reaction conditions, etc., and achieve reusable performance Good, simple recycling process, stable catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 11

[0045] Catalyst preparation:

[0046] P 123 (EO20PO70EO20) (MW: 5000) was purchased from Sigma; orthoethyl silicate (TEOS), 1,3,5 trimethylbenzene (analytical pure) and tetrahydrate and calcium nitrate (analytical pure) were purchased from Shanghai Sinopharm Chemical Reagent Co., Ltd. Company; concentrated hydrochloric acid (HCl) (36%-38%) analytically pure, purchased from Laiyang Economic and Technological Development Zone Fine Chemical Plant.

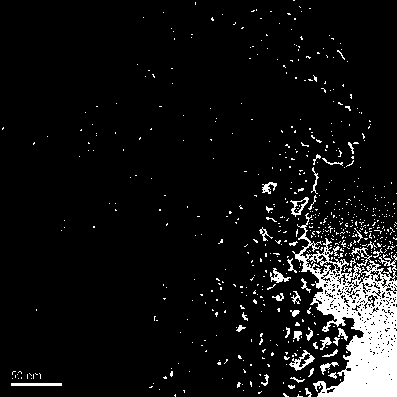

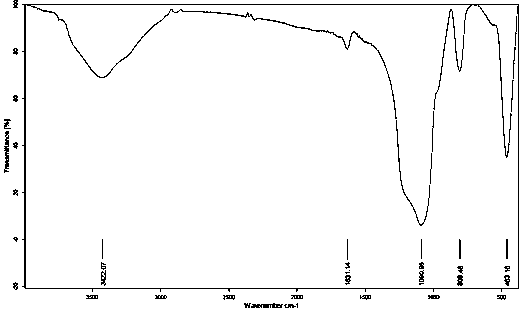

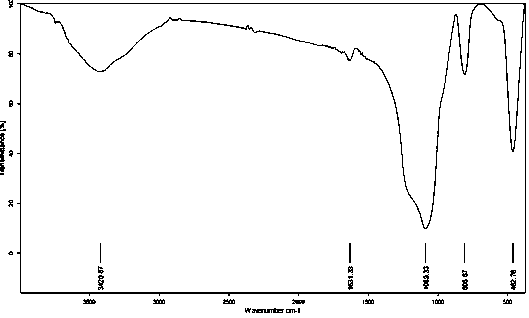

[0047] Preparation of MCF: Weigh 2 g of commercially available P123 as a template, soak it in an aqueous HCl solution with a concentration of 1.6 mol / L, stir at 38°C for 2 hours until P 123 Dissolve completely, add 2g of mesitylene and 23mg of NH 4 F is a pore-enlarging agent. After continuing to stir for 2 hours, add 4.5g of TEOS (tetraethyl orthosilicate) dropwise and acidify for 24 hours, then transfer it to a hydrothermal synthesis kettle for crystallization at 100°C for 24 hours, and filter, wash and dry the product , roasting...

Embodiment 12

[0052] In an autoclave with a thermometer, add 5g of PLA in sequence (the molecular weight of PLA is 2.0×10 4 ~6.0×10 4 g / mol), 11.2g methanol, 0.83g CaO / MCF (prepared in Example 1.1), stirred and reacted (300 rpm) at 120°C for 3h, after the reaction, filtered under reduced pressure to filter out unreacted polylactic acid The unreacted methanol is recovered by atmospheric distillation at 70°C with the catalyst and filtrate, and the product methyl lactate is obtained by distillation under reduced pressure at 100°C. The product 6.2 g of methyl lactate was obtained. The alcoholysis rate of polylactic acid is 92%, and the selectivity of methyl lactate is 85.90%.

Embodiment 13

[0054] In an autoclave with a thermometer, add 5g of PLA, 11.2g of methanol, and 0.66g of CaO / MCF (prepared in Example 1.1) in sequence, and stir the reaction (300 rpm) at 125°C for 3h. Filtrate under reduced pressure to filter out unreacted polylactic acid and catalyst. The filtrate is distilled at 70°C under normal pressure to recover unreacted methanol, and then distilled under reduced pressure at 100°C to obtain the product methyl lactate. The product 6.1 g of methyl lactate was obtained. The alcoholysis rate of polylactic acid was 91.4%, and the selectivity of methyl lactate was 84.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com