Tea fertilizer and preparation method thereof

A fertilizer and tea technology, which is applied in the field of tea fertilizer and its preparation, can solve the problems of excessive pesticide residues in tea, lack of prevention and control of diseases and insect pests, and damage to the ecological environment of tea gardens, so as to enhance the prevention and control of tea diseases and insect pests, improve the effect of insecticidal and antibacterial, and prevent and control The effect of tea pests and diseases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

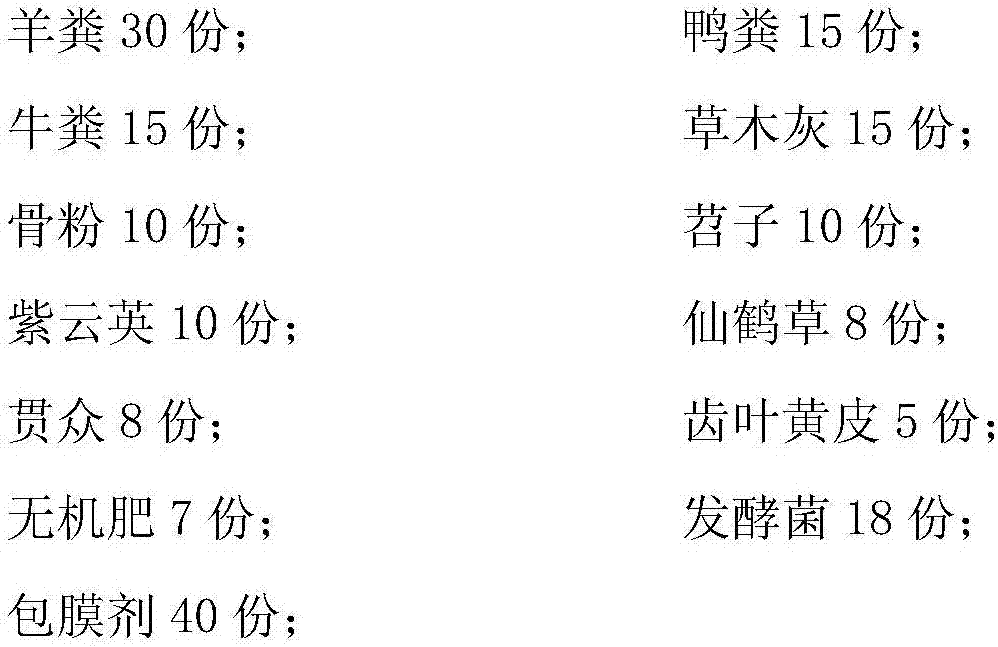

Embodiment 1

[0029] 1) Preparation of coating agent

[0030] S1: by weight, take the following raw material components:

[0031] 5 parts of chitosan; 3 parts of starch;

[0032] 4 parts of bentonite; 1 part of iron acetate.

[0033] S2: Dissolve the weighed chitosan in acetic acid solution at 55°C to prepare a chitosan solution with a mass concentration of 5%; mix the weighed starch and water at a volume ratio of 1:8, Gelatinize at 80°C for 30 minutes to obtain starch gelatinization solution; crush and sieve the weighed bentonite to 100 mesh to obtain bentonite powder;

[0034] S3: Mix and stir the chitosan solution, the starch gelatinization solution, the bentonite powder and ferric acetate until uniform, then add glycerin and polyethylene glycol to continue stirring, heat up to 90°C under stirring, and drop For the cross-linking agent, continue to stir for 1 hour, add ammonium chloride dropwise, continue to stir for 10 minutes, and degas under reduced pressure to obtain the coating ag...

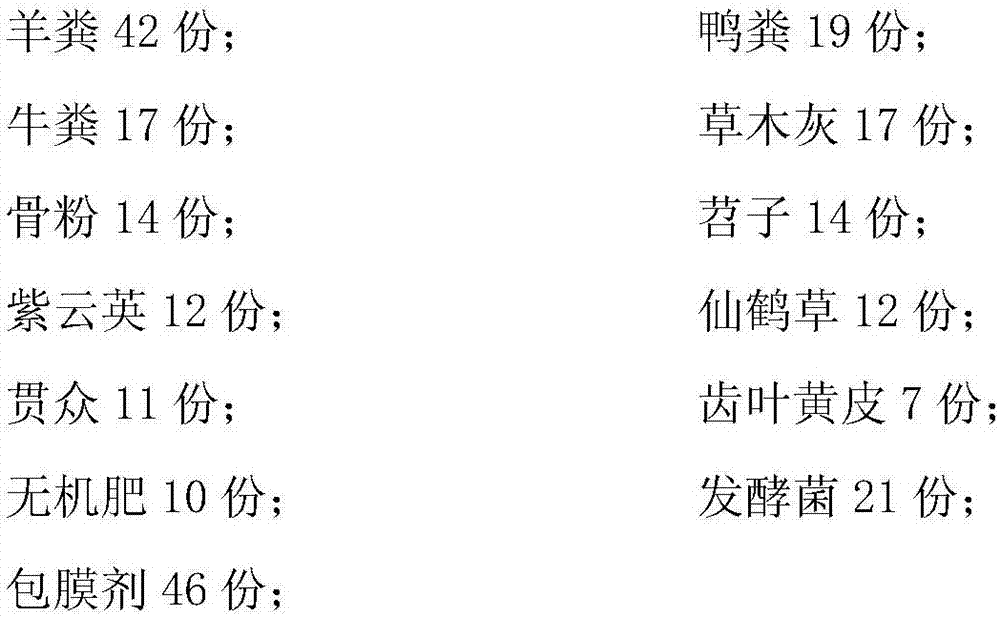

Embodiment 2

[0044] 1) Preparation of coating agent

[0045] S1: by weight, take the following raw material components:

[0046] Chitosan 7 parts; Starch 5 parts;

[0047] 5 parts of bentonite; 2 parts of iron acetate.

[0048] S2: Dissolve the weighed chitosan in acetic acid solution at 55°C to prepare a chitosan solution with a mass concentration of 5%; mix the weighed starch and water at a volume ratio of 1:8, Gelatinize at 80°C for 30 minutes to obtain starch gelatinization solution; crush and sieve the weighed bentonite to 100 mesh to obtain bentonite powder;

[0049] S3: Mix and stir the chitosan solution, the starch gelatinization solution, the bentonite powder and ferric acetate until uniform, then add glycerin and polyethylene glycol to continue stirring, heat up to 92°C under stirring, and add dropwise For the cross-linking agent, continue to stir for 1 hour, add ammonium chloride dropwise, continue to stir for 10 minutes, and degas under reduced pressure to obtain the coating a...

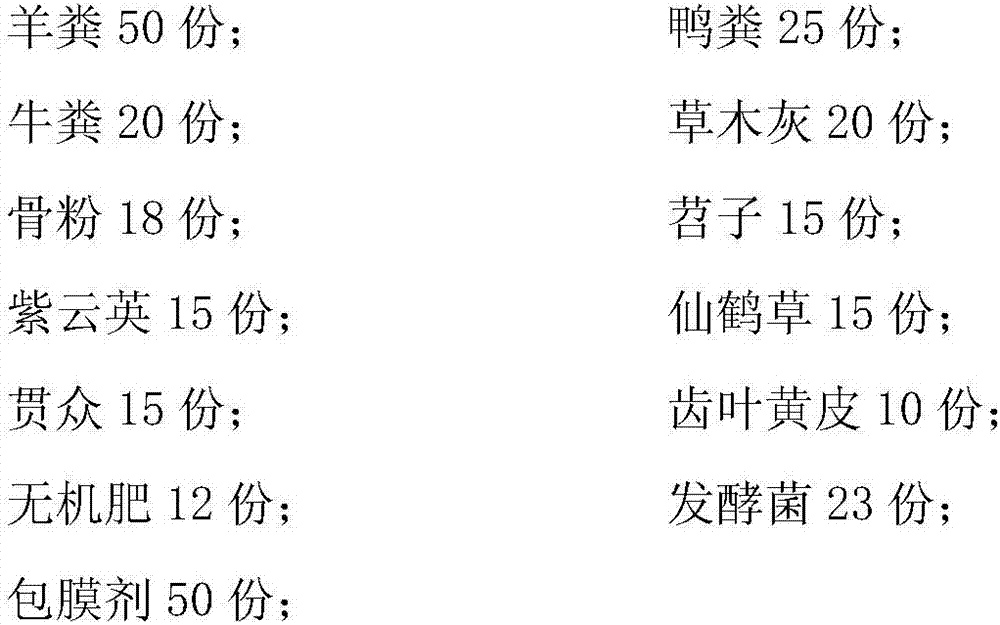

Embodiment 3

[0059] 1) Preparation of coating agent

[0060] S1: by weight, take the following raw material components:

[0061] 10 parts of chitosan; 8 parts of starch;

[0062] 8 parts of bentonite; 3 parts of iron acetate.

[0063] S2: Dissolve the weighed chitosan in acetic acid solution at 55°C to prepare a chitosan solution with a mass concentration of 5%; mix the weighed starch and water at a volume ratio of 1:8, Gelatinize at 80°C for 30 minutes to obtain starch gelatinization solution; crush and sieve the weighed bentonite to 100 mesh to obtain bentonite powder;

[0064] S3: Mix and stir the chitosan solution, the starch gelatinization solution, the bentonite powder and ferric acetate until uniform, then add glycerin and polyethylene glycol to continue stirring, heat up to 95°C under stirring, and drop For the cross-linking agent, continue to stir for 1 hour, add ammonium chloride dropwise, continue to stir for 10 minutes, and degas under reduced pressure to obtain the coating ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com