Sludge pretreatment device

A pretreatment device and sludge technology, applied in the direction of dewatering/drying/concentrating sludge treatment, etc., can solve the problems of affecting the dehydration rate, slow conveying speed, low production efficiency, etc., and achieve stable movement and simple device structure. , the effect of high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

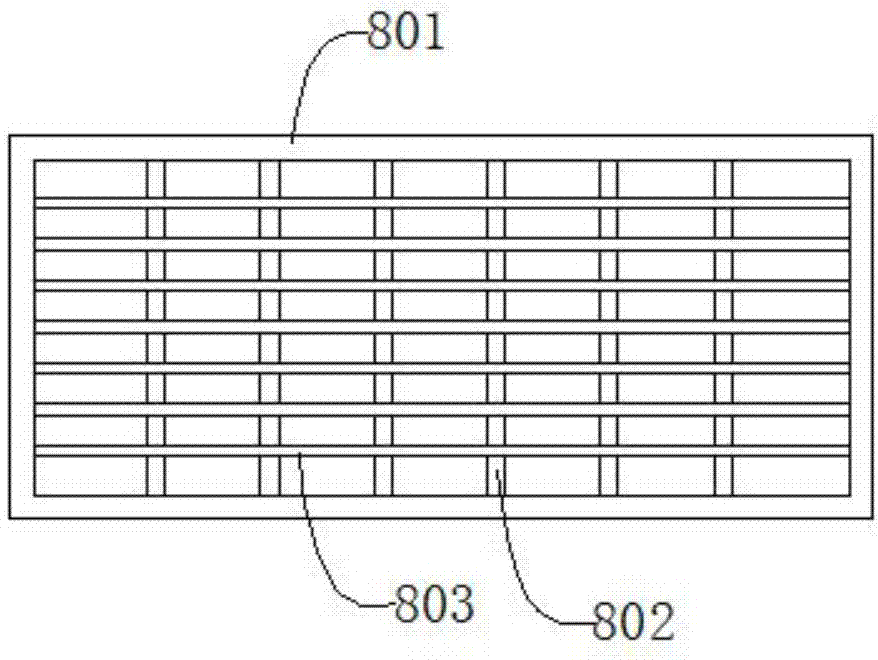

[0037] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6As shown, a sludge pretreatment device includes a support plate 1, a bracket 2, a feeding nozzle 3, an upper feeding bin 4, a motor 5, an impeller 6, a feeding nozzle 7, a lower grid 8, a guide rod 9, an upper Grille 10, swing mechanism 11, connecting plate 12, limit plate 13, steel ball 14, described support 2 is positioned at the upper end of support plate 1, and described support 2 is connected with support plate 1 threadedly, and described feeding nozzle 3 is located at the lower end of the support plate 1, the feeding nozzle 3 is threadedly connected with the support plate 1, the upper material bin 4 is located at the upper end of the bracket 2, the upper material bin 4 is threadedly connected with the bracket 2, and the motor 5 is located at the upper end of the upper feed bin 4, the motor 5 is screwed to the upper feed bin 4, the impeller 6 is located at the lower end of the motor 5 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com