Roll paper cutting device

A cutting device, a technology for paper rolls, applied in the direction of winding strips, transportation and packaging, sending objects, etc., can solve the problems of troublesome loading and unloading, cumbersome locking and unlocking, inability to separate, etc., to achieve moving and The effect of convenient loading and unloading, flexible and convenient retraction, and high quality of pressing paper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0030] figure 1 It is a schematic diagram of a large web and a small web. The function of the web cutting device is to cut the large web and rewind it into a small web.

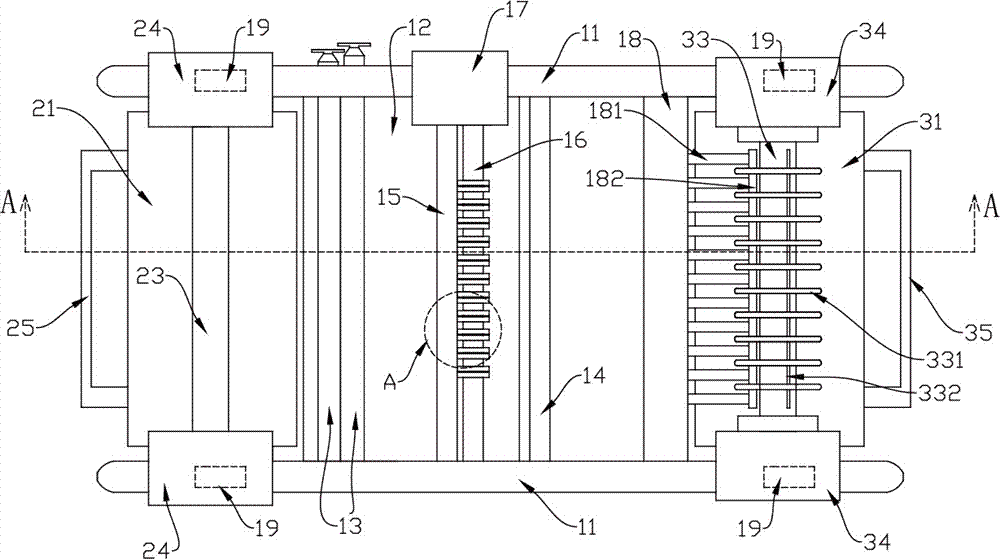

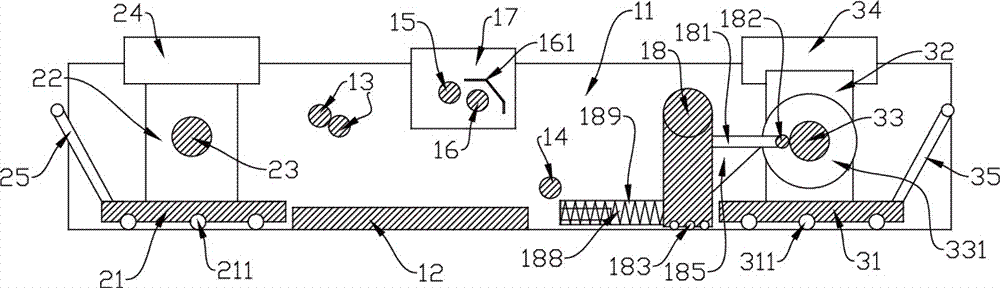

[0031] See Figure 2~11 , The web cutting device involved in the present invention, a web cutting device in the present invention, includes a main body, a cutting assembly, a paper feeding platform, a paper discharging platform, and a paper pressing device.

[0032] The main body includes two vertical main body side plates 11 arranged in parallel, and the two main body side plates 11 are connected by a connecting plate 12 to maintain structural stability. One end of the main body is a paper input end, and the other end is a paper output end. The main body is provided with guide rollers 13, 14 and a cutting assembly.

[0033] Described cutting assembly comprises th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com