Diamond abrasive disc based on spot welding and manufacture process thereof

A manufacturing process, diamond technology, applied in the direction of manufacturing tools, metal processing equipment, grinding devices, etc., can solve the problems of relatively large heat-affected zone, high production cost, performance impact, etc., to achieve easy control operation, avoid random sliding, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

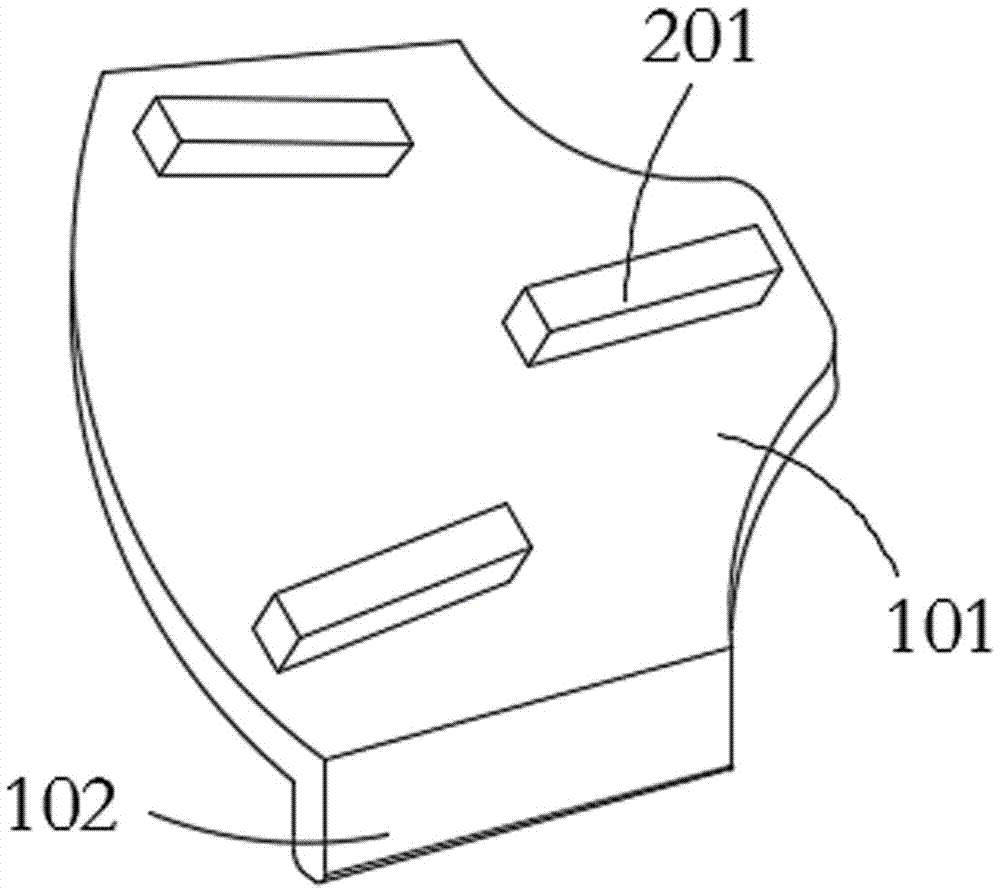

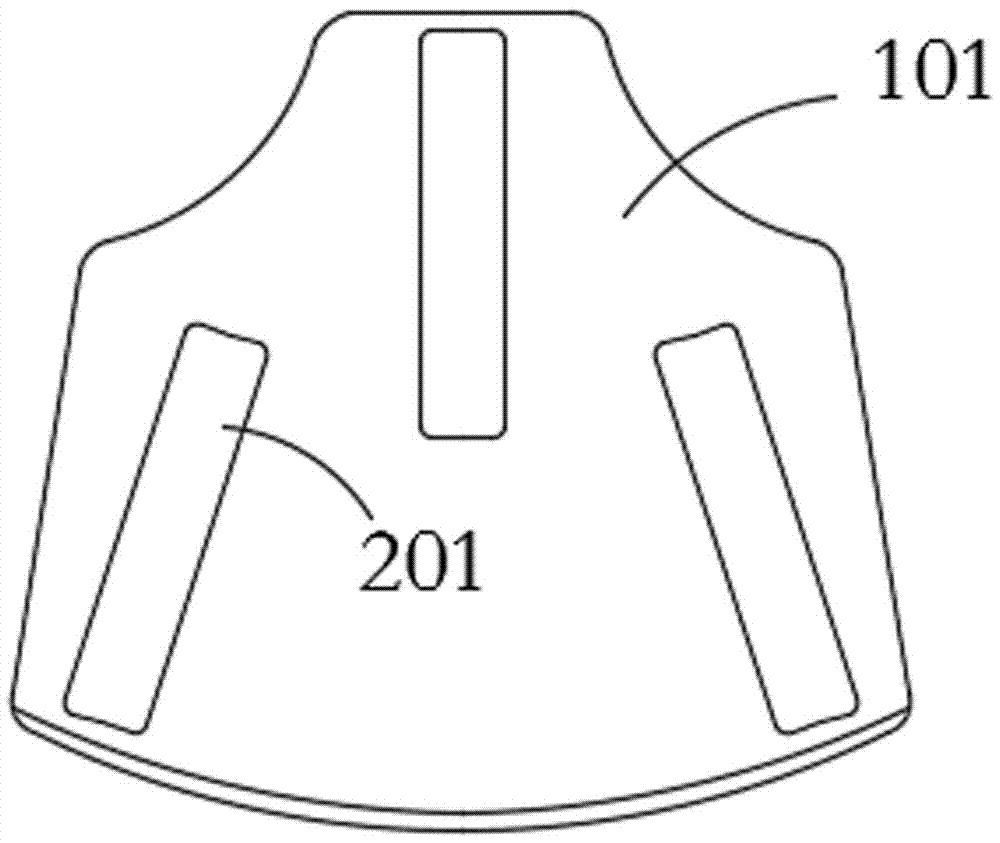

[0038] see Figure 1-8 , the present invention provides a technical solution: a diamond grinding disc based on spot welding, comprising an iron substrate 101, the top surface of the iron substrate 101 is welded with a cutter head assembly 201, and the cutter head assembly 201 is a cuboid structure, its There are three groups, which are evenly distributed on the top surface of the iron sheet substrate 101 .

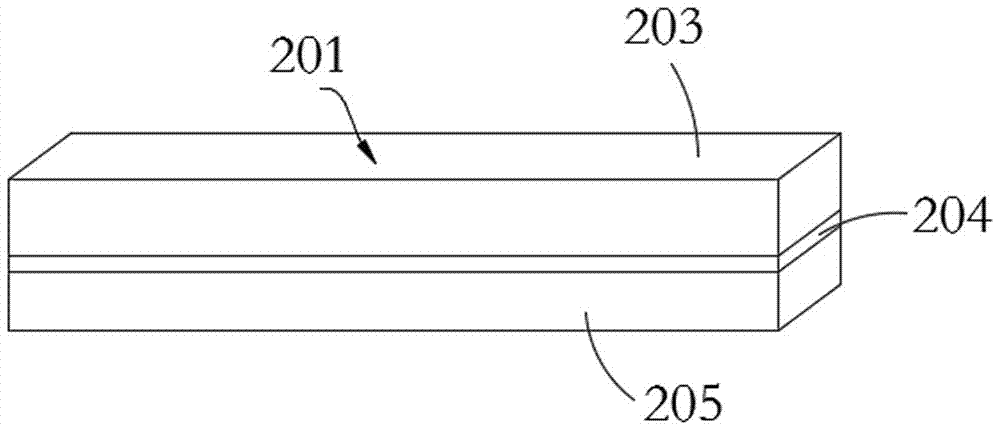

[0039] see Figure 1-5 , the cutter head assembly 201 comprises an iron bar 205, a connecting layer 204 and a cutter head 203, the iron bar 205 is fixed on the iron sheet substrate 101 by spot welding, the connecting layer 204 is positioned on the top surface of the iron bar 205, and the cutter head 203 is positioned at the connecting layer 204 Above, the cutter head 203 and the iron bar 205 in the cutter head assembly 201 can be firmly fused together by using the connecting layer 204 at a relatively low temperature.

[0040] The connection layer 204 here can also be an ...

Embodiment 2

[0057] see Figure 1-8 , the present invention provides a technical solution: a diamond grinding disc based on spot welding, comprising an iron substrate 101, the top surface of the iron substrate 101 is welded with a cutter head assembly 201, and the cutter head assembly 201 is a cuboid structure, its There are three groups, which are evenly distributed on the top surface of the iron sheet substrate 101 .

[0058] see Figure 1-5 , the cutter head assembly 201 comprises an iron bar 205, a connecting layer 204 and a cutter head 203, the iron bar 205 is fixed on the iron sheet substrate 101 by spot welding, the connecting layer 204 is positioned on the top surface of the iron bar 205, and the cutter head 203 is positioned at the connecting layer 204 Above, the cutter head 203 and the iron bar 205 in the cutter head assembly 201 can be firmly fused together by using the connecting layer 204 at a relatively low temperature.

[0059] The connection layer 204 here can also be an ...

Embodiment 3

[0076] see Figure 1-8 , the present invention provides a technical solution: a diamond grinding disc based on spot welding, comprising an iron substrate 101, the top surface of the iron substrate 101 is welded with a cutter head assembly 201, and the cutter head assembly 201 is a cuboid structure, its There are three groups, which are evenly distributed on the top surface of the iron sheet substrate 101 .

[0077] see Figure 1-5 , the cutter head assembly 201 comprises an iron bar 205, a connecting layer 204 and a cutter head 203, the iron bar 205 is fixed on the iron sheet substrate 101 by spot welding, the connecting layer 204 is positioned on the top surface of the iron bar 205, and the cutter head 203 is positioned at the connecting layer 204 Above, the cutter head 203 and the iron bar 205 in the cutter head assembly 201 can be firmly fused together by using the connecting layer 204 at a relatively low temperature.

[0078] The connection layer 204 here can also be an ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com