Stretching cushion locking device

A locking device and a stretching pad technology, applied in the field of forging equipment, can solve the problems of large size, increased construction cost, complex structure, etc., and achieve the effects of satisfying strength and life, convenient manufacturing and maintenance, and simplifying equipment mechanism.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

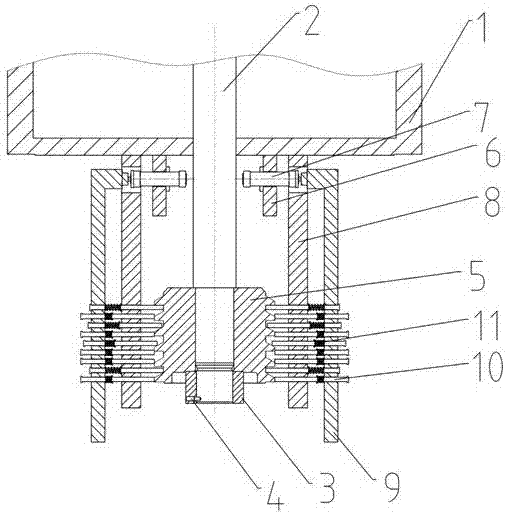

[0023] According to the first embodiment of the present invention, a locking device for stretching pads is proposed, which can be used to lock the stretching pads on the press, see the attached figure 1 , The structure of the device includes a tension pad cylinder 1, a pull rod 2, a nut 3, a pin 4, a locking sleeve 5, a mounting plate 6, a cylinder 7, a bracket 8, a moving plate 9, a locking column 10, and a spring 11.

[0024] The pull rod 2 is connected with the stretch pad piston (not shown in the figure), and moves up and down with the piston. The bottom of the stretch pad cylinder 1 is located on both sides of the pull rod 2 and is fixedly installed with a mounting plate 6 and a bracket 8. The mounting plate 6 is installed on On the inner side of the bracket 8, a cylinder 7 is fixedly installed on the mounting plate 6, and the piston rod of the cylinder 7 passes through the relief hole on the bracket 8 to connect to the moving plate 9 outside the bracket 8, so that the cyl...

Embodiment 2

[0027] The difference between this embodiment and Embodiment 1 is that the mechanical transmission device of screw feed is used to replace the cylinder 7, and other structures are the same as that of Embodiment 1. The mechanical transmission device of screw feed is the same as the cylinder, and belongs to The driving parts with reliable and stable power and simple structure have lower requirements on installation conditions and working environment than hydraulic systems.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com