Pressure vessel valve suitable for automatic locking

A pressure vessel and automatic locking technology, which is applied in the field of pressure vessel valves, can solve problems such as misopening of the hand wheel, and achieve the effects of avoiding misopening, improving the limit effect, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

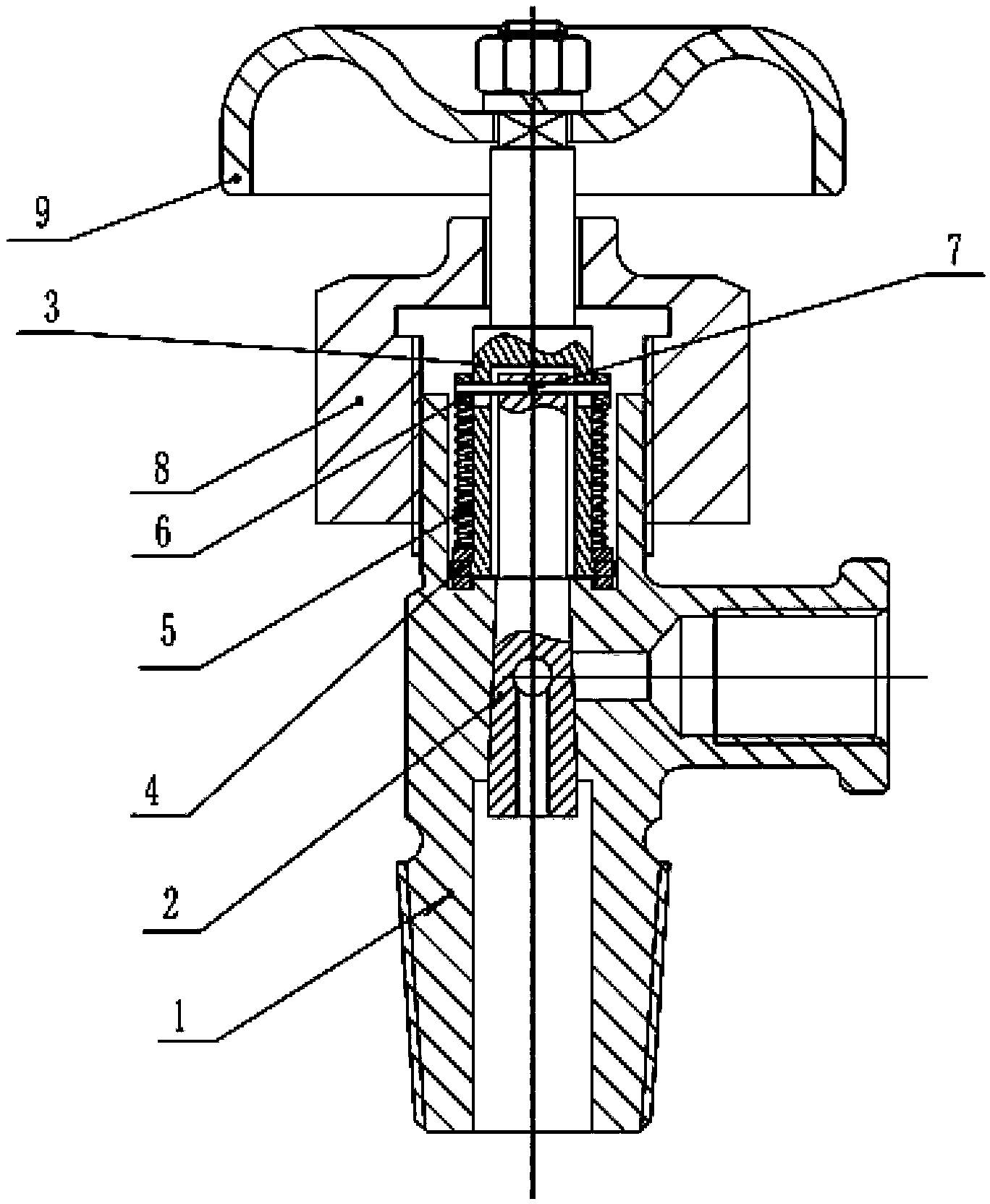

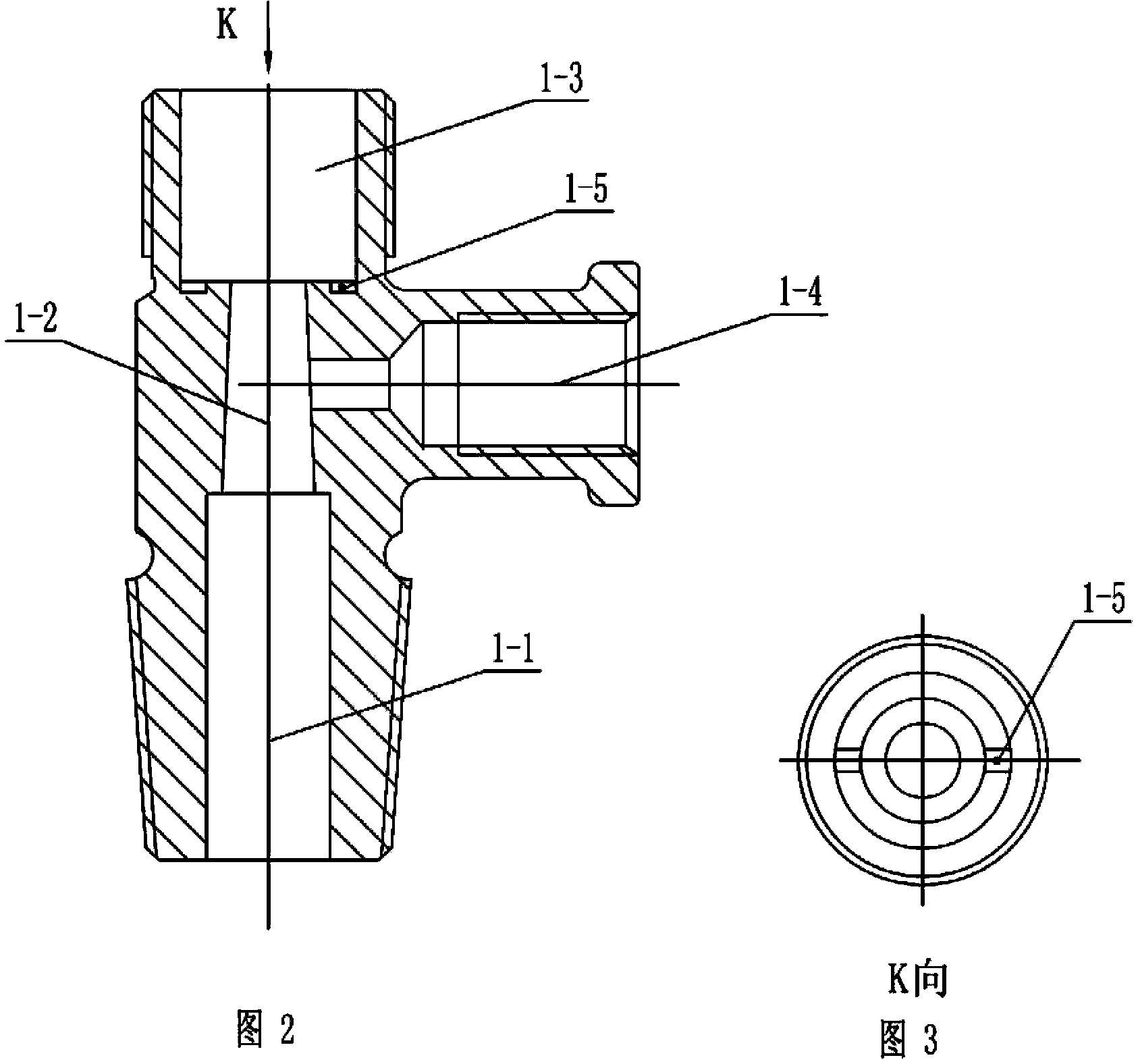

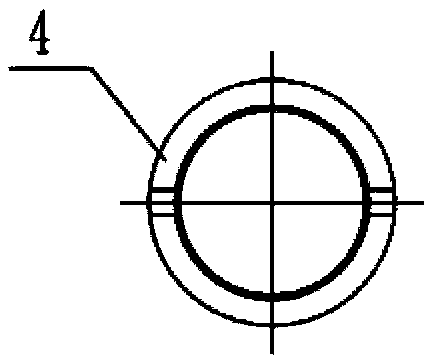

[0025] See Figure 1-10 , the pressure vessel valve suitable for automatic locking in this embodiment includes: a valve body 1, a valve stem 2 arranged in the valve body 1, a lock lever 3 arranged at the upper end of the valve stem 2, and a hand lever arranged at the top of the lock lever 3. Wheel 9; valve stem 2 includes: conical section 2-1 and cylindrical section 2-2 connected to the upper end of the conical section 2-1; valve body 1 includes: the first cylindrical cavity 1-1 at the bottom, the same A conical cavity 1-2 with an axis set at the upper end of the first cylindrical cavity 1-1, which is suitable for sealing fit with the conical section 2-1 of the valve stem 2, and a coaxial line set at the conical cavity The second cylindrical cavity 1-3 at the upper end of 1-2; the side wall of the conical cavity 1-2 is provided with an exhaust port 1-4; the diameter of the upper port of the conical cavity 1-2 is smaller than the second cylindrical cavity 1-3 in diameter to fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com