Metal-tube sectional material rewinder

A pipe profile and rewinding machine technology, which is applied in the field of metal pipe profile preparation, can solve the problems of uneven pipe arrangement, high energy consumption, and low efficiency, and achieve the effects of shortening the processing cycle, optimizing the process, and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

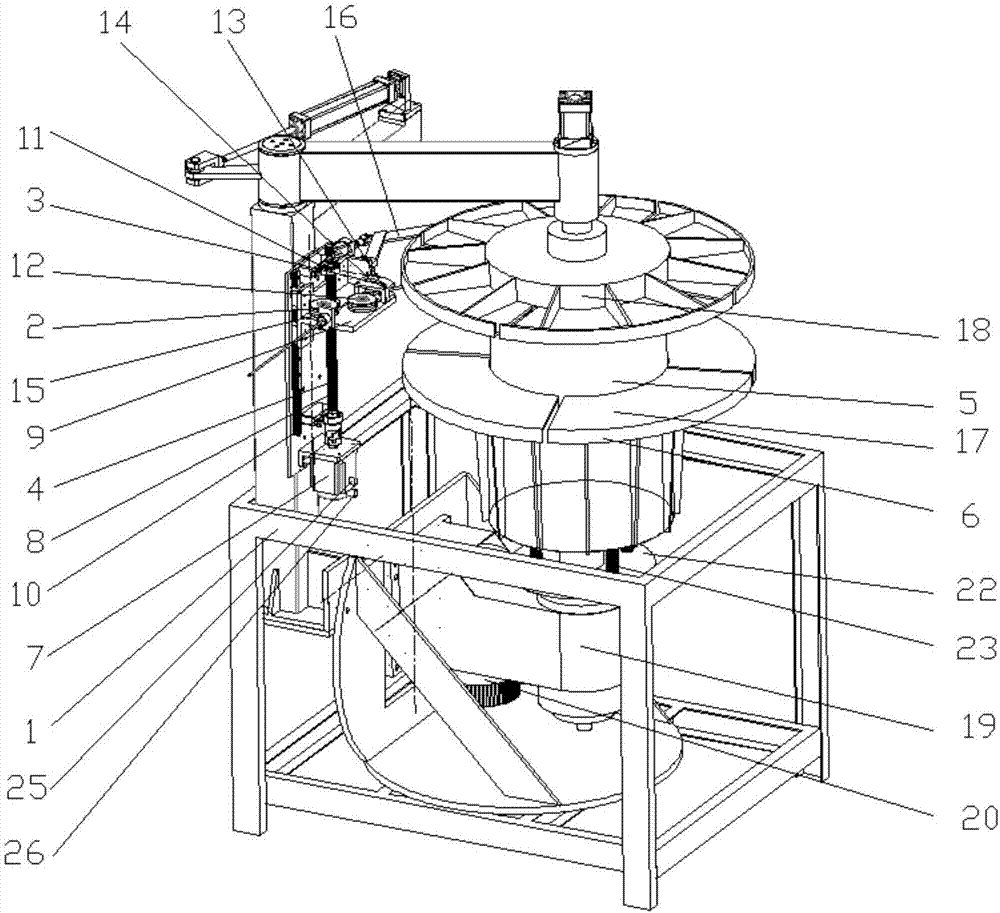

[0031] Such as figure 1 As shown, it is a metal pipe profile rewinding machine, including a machine frame 1, and the upper left side of the frame 1 is provided with a metal pipe guiding device 2 and a sizing and pre-bending mechanism 3. There is an automatic pipe arrangement control mechanism 4 on the left side, and a motor-driven pipe winding shaft 5 and an unwinding mechanism 6 are provided in the middle of the frame. The copper pipe to be rewound is placed in the guide device 2, and the output metal is guided After the pipe is bent by the sizing and pre-bending mechanism 3, it is rewound and collected at the pipe winding shaft 5 under the control of the automatic pipe discharge control mechanism 4, and finally uncoiled by the unwinding mechanism 6 after rewinding and rewinding.

[0032] Specifically, the automatic pipe arrangement control mechanism 4 described in the automatic pipe arrangement control mechanism includes a motor 7, a screw guide shaft assembly 8, a fixed sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com