A kind of preparation method of waste zinc-manganese battery-biomass adsorbent

A biomass adsorbent, zinc-manganese battery technology, applied in chemical instruments and methods, alkali metal compounds, alkali metal oxides/hydroxides, etc., can solve the problem of consumption of chemical activators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The invention provides a method for preparing a waste zinc-manganese battery-biomass adsorbent, the specific steps are as follows:

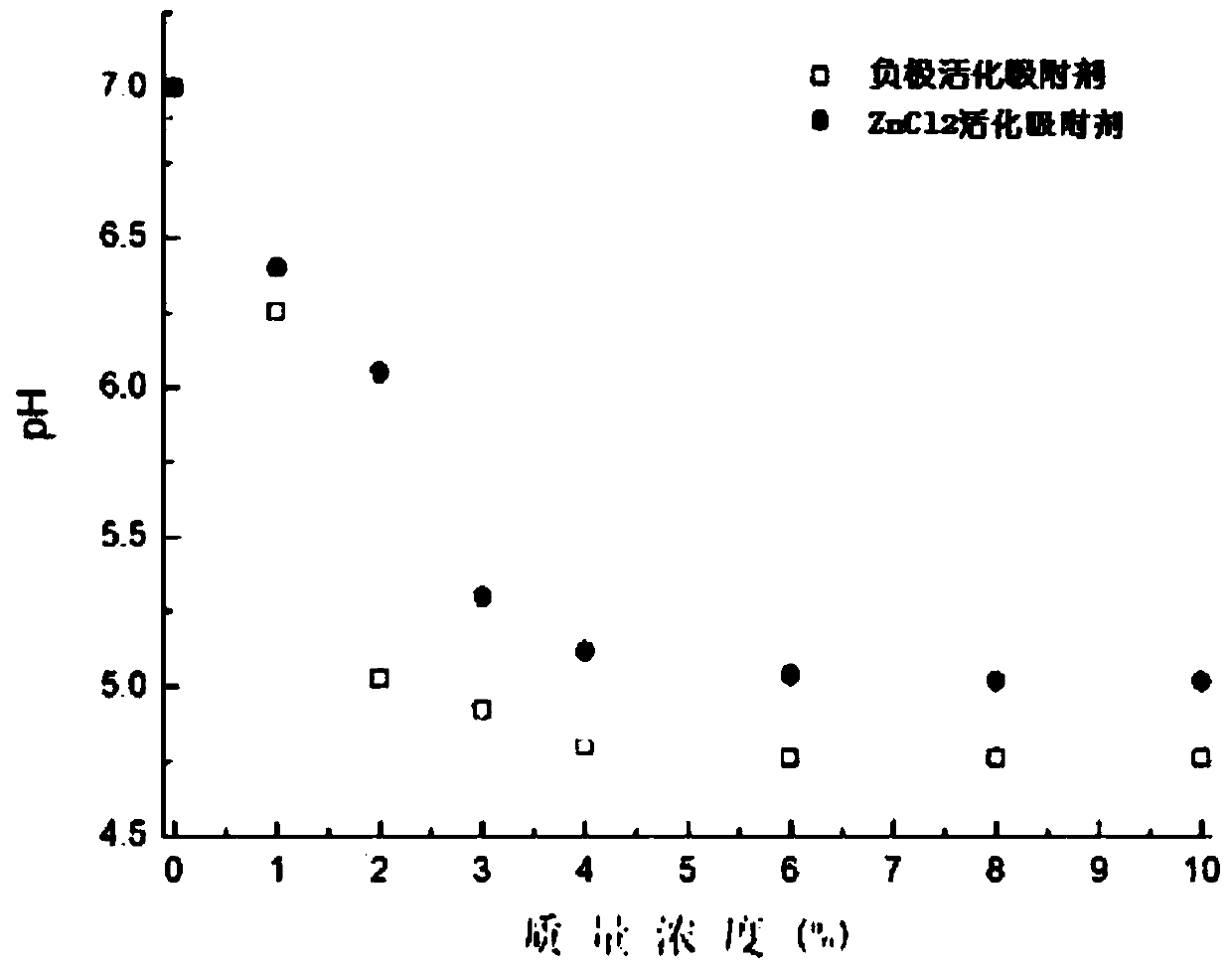

[0031] Step 1, determine the amount of negative electrode material and hydrochloric acid: calculate and generate 2mol / L~3mol / L ZnCl respectively 2 The mass of the required negative electrode material and the volume of hydrochloric acid of 8mol / L~12mol / L; wherein the negative electrode material is converted according to the mass percentage content of 50%~60% of the tested Zn;

[0032] Among them, in the process of weighing the negative electrode material and hydrochloric acid, in order to make the adsorbent prepared by the preparation method of the present invention have better performance, there will be an excess of no more than 5% by mass, but it will not affect the entire preparation process;

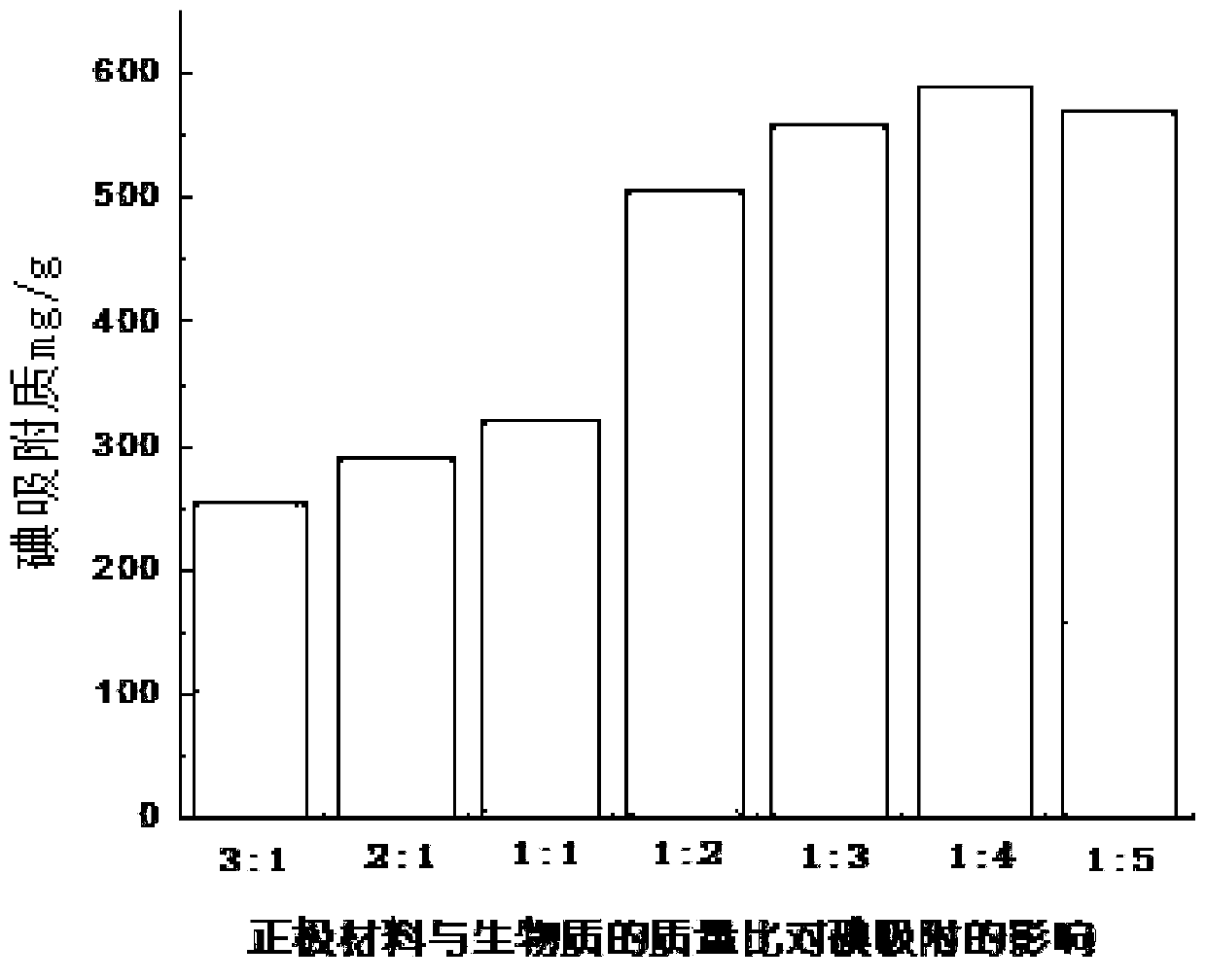

[0033] Step 2, weighing of deionized water, positive electrode material and biomass: weigh the deionized water, positive electrode material and b...

Embodiment 1

[0050] Calculate and generate 2mol / L ZnCl respectively 2 The quality of required negative electrode material and the volume of the hydrochloric acid of 8mol / L; Wherein the mass percent content of the Zn that negative electrode material is tested is 50% and is converted, and the consumption of negative electrode material and hydrochloric acid is respectively 20g and 50ml; The mass and the quality of the negative electrode material are 2.5:1 to weigh 50ml of deionized water, the total mass of the positive electrode material and biomass and the sum of deionized water and hydrochloric acid are to weigh the positive electrode material and biomass according to the solid-liquid ratio of 1:4, the positive electrode The material and sawdust are 20g according to the mass ratio of 1:4, and the sawdust is crushed and mixed with the positive electrode material as a mixed raw material; the obtained negative electrode material is added to a 250ml flask, and 50ml of deionized water is added fo...

Embodiment 2

[0052] Calculate and generate 3mol / L ZnCl respectively 2 The quality of required negative electrode material and the volume of the hydrochloric acid of 12mol / L; Wherein the mass percent content of the Zn that negative electrode material is tested is 56% and is converted, and the consumption of negative electrode material and hydrochloric acid is respectively 20g and 50ml; The quality and negative electrode material quality are 3:1 to measure deionized water 60ml, the total mass of positive electrode material and biomass and the sum of deionized water and hydrochloric acid are 1:4 to weigh positive electrode material and biomass by solid-liquid ratio, positive electrode The material and peanut shells are taken at a mass ratio of 1:5 to take 30g, and the peanut shells are crushed and mixed with the positive electrode material to form a mixed raw material; the obtained negative electrode material is added to a 250ml flask, and 60ml of deionized water is added to carry out a 15min ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com